| Previous

Year |

|---|

| Next Year |

| New Sets for 1995 |

| New Parts for 1995 |

|

|

||||

1995 - Tech Play/Build

|

Sets |

|

8210 Nitro GTX Bike |

8225 Road Rally V |

8280 Fire Engine |

|

8412 Nighthawk |

8422 Circuit Shock Racer |

8440 Formula Flash |

8460 Pneumatic Crane Truck |

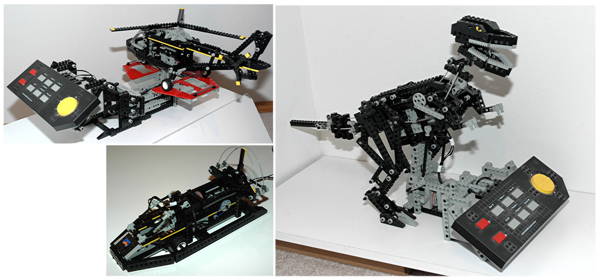

8485 Control Center II

|

|

Parts |

|

| Wheels and Tires Two new sizes of wheels and tires were introduced which matched the general aspect ratio and tread pattern of the big 81.6 x 34 ZR from set 8880. The new mid sized tires are called 49.6 x 28 VR and the smallest are 30.4 x 14 VR. What is the difference between the title "VR" and "ZR"? I have no idea other than that this may be a speed rating. Rack Gear The previous rack gear had been a 1x4 unit which attached to the top of a plate using studs. The new 1x8 rack gear pictured was something different. Beside being longer, it also had holes at the end to which ball joint or axles could be attached. Additionally, there were no stud tubes on the bottom. This meant that it could still sit over a plate, but could also slide along the studs on that plate. This part became very common for decades and was later released in other lengths. Stopped Axle This handy little part looks like a 3L axle, but has the additional feature of a stop collar and stud on one end. If inserted into the hole in a Technic beam, the stop collar drops into the counterbore on the beam and disappears. This leaves you with an exposed stud on one end and a rotatable axle which which will not pull out of the hole. This little part only existed in dark gray until 2010 and has been used many times in many models. Bevel Gear The old standard 14 tooth bevel gear was replaced this year with a 12 tooth bevel gear. Beside the obvious difference in tooth count, the other difference is that the new bevel gear has a solid web behind the teeth which gives it considerable extra strength. Link A 16L link (tie rod) was introduced to Technic. This long two-force member was only used in a single Technic model, 8235. Handle Many original Technic sets used a large pulley as a crank in combination with a pin as a handle. Later, it became more common to use the smaller pulley with a half pin. The disadvantage to this is that the 1/2 pin does not rotate in the hole and therefore has to rotate in your fingers as you turn the crank. This was solved in 1995 with a little round handle that snapped over the pin and rotated allowing faster, easier cranking. For some reason, this part only existed in 1995 and was never used again. The disappearance of this part is a mystery since I see no obvious flaw in it, but it is quite rare as a result of its short life. Pin Joiner A round pin joiner was introduced. This part is the length of a pin and can lock a pin inserted from each end due to a circumferential groove in the center halfway along the length. It can either be used to extend the length of a pin or can be slid over an axle as a spacer or decorative element. Liftarm A 1x3 liftarm was introduced. This very important part was a significant harbinger of the future. 6 years earlier in 1989 the first liftarm was introduced (1x4). This 1x3 liftarm also has an axle slot at either end and a hole in the center. Unlike the earlier part, it is not 1 stud thick at one end but remains 1/2 stud thick along the entire length. Many, many more liftarms would be introduced in the future and in fact would eventually become the primary Technic construction part almost entirely replacing traditional beams. Flex System End Connector A new kind of flex system end connector was introduced. The previous connector had to be pushed onto the cable from the side. The bending stress from this often fractured the cable. With the new connector, the cable is inserted and then a flap is snapped closed over the cable ferrule which prevents it from pulling out. This improved method made the flex system much more durable. In addition to the standard new end connector, there was also an end to end connector which allowed two cables to be connected with an axle hole in the center. Gearboxes There were also two new gearboxes introduced which made the assembly of certain gear combinations simpler for younger children. At least one of the two gearboxes were used in the majority of the Tech Play models. The worm gearbox (shown in yellow in the animation) supported a 24 tooth spur gear and a worm gear along with their associated perpendicular axles. With the worm axle used as an input, this gearbox allowed a 24:1 reduction and could be integrated into models using the studs on top and bottom or the holes on the sides. The bevel gearbox (shown in white in the animation) allowed a pair of perpendicular bevel gears to be mated in either a horizontal or vertical plane and provided support for the axles. |

|