Features

|

|

Pneumatics

This model contains a double acting pneumatic system. The components of

this system are connected with rubber tubing.

A single pump provides air pressure. Depression of the piston

produces pressure. The pressure is fed to an inlet of a selector

valve (switch) with two outputs. Selection of the switch in

either direction allows pressure to flow to either chamber of the

actuators.

Finally, there are two pneumatic actuators which have ports at the

head and rod ends

to accept input from the switch. Head end pressure extends the

piston, while rod end pressure retracts it. This model uses a

pair of actuators in series connected via rotors.

|

|

|

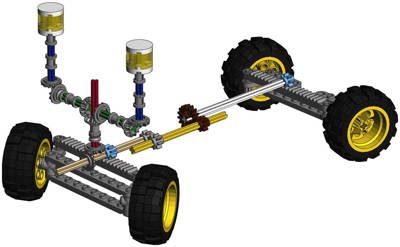

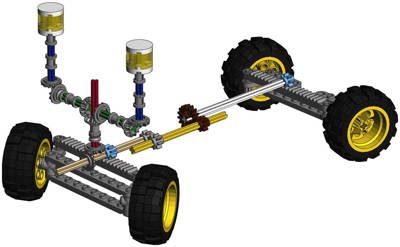

Steering

The front wheels can be steered using a pair of overhead "hand of god"

controls. The steering

knobs are designed to look like flashing lights. The overhead

control turns the blue axles in the computer image which then turn the

green axles in parallel through a set of bevel gears. The

vertical red axle mates with both bevel gears, linking the two inputs

together and transferring torque downward. The longitudinal axle

shown in tan then drives the front gear rack. Two more

pairs of gears on the brown and white axles reach the rear axle which

turns in the opposite direction. The steering mechanism itself

uses the steering arms

and toothed links.

The two light blue pinion gears move the front and rear axles at

different rates which results in a larger steering lock in front.

This is due to the brown spur gear pair (16:8) which halves the

rotation of the rear steering axle. The center of rotation is

then roughly at the central unsteered axle.

|

Click for an animation of the

steering in motion. |

|

Luffing Boom

The boom can be pivoted from a position parallel to the ground up to an

angle of about 60 degrees. A pair of pneumatic actuators drive

this motion. They operate in series and extend to luff the

boom.

This is the first time pneumatic actuators were used in series.

Since no special parts existed to accomplish this connection, they are

attached with a pair of rotors and some axles and pins. To keep

the actuators from rolling around their long axis, another pair of

black links on the side clock them to the angle of the boom.

One bit of unexpected design here is that the retract ports of the

cylinders are also plumbed. This has two effects. First, it

slows the descent of the boom since the retract ports cannot just suck

freely from atmosphere. Second, it allows the boom to actually be

pressurized down to hold it down against the chassis. This allows

you to carry around the model using the boom as a convenient handle!

|

Click for an animation of the

boom

luffing.

|

|

Telescoping Boom

The boom can telescope to approximately 180% of its original length. A

smaller inner boom is constructed of beams topped by gear racks.

It rides upon a support made from another set of black beams

constructed upside down. The resulting smooth surface supports

the telescoping motion.

A crank on the right side drives an axle parallel

to the boom via a worm gear and an 8 tooth pinion. This axle runs

the entire

length of the boom, spliced with another pair of 8 tooth spur

gears. At the upper end of

the boom, the

rotation is turned 90 degrees through a set of 12 tooth bevel

gears. The

cross axle contains a final 16 tooth spur which translates the entire

inner

boom axially as it mates with the rack.

There are stops at either end of the inner boom to prevent it from

extending or retracting too far. The cantilever moment of the

inner boom is significant, so a solid structure braced with vertical

liftarms and rotors is required to keep the whole thing from prying

apart.

As can be seen in the animation, the sheave is effectively raised by

the telescoping of the boom. Since the length of the boom has

increased, less cable is available in the vertical direction.

|

Click for an animation of the

boom

telescopic motion.

|

|

Hoist

A hoist is available which uses LEGO® string to

lift a sheave. A pulley wheel on the right side is used as a

crank

and directly

rotates an axle to which the string is affixed. This axle acts as

a

winding drum and raises and lowers the sheave.

A 16 tooth gear on the left side acts as a ratchet which mates with a

pawl. This supports the tension in the cable.

Even though the metal hook is fairly heavy, sometimes when the cable is

being payed out the weight is not enough to unspool it resulting in a

rat's nest of tangled cable.

|

Click for an animation of the hoist

in

motion.

|

|

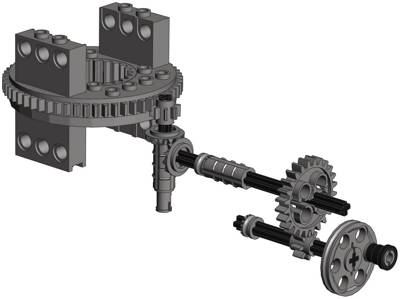

Slewing

The rotation of the superstructure is accomplished via a crank on the

rear. The crank turns a set of 8 and 24 tooth spur gears, then a

pair of 12 tooth bevels. A final 8 tooth pinion mates with the

outer 56 tooth ring gear on the top of the turntable. This

results in a total reduction of (24:8 x 12:12 x 56:8) = 21:1.

Because no pneumatic hoses or axles pass between the base and the boom,

the

boom can slew 360 degrees without becoming twisted.

|

|

|

Outriggers

There are two pairs of outriggers behind the front and rear wheels

which are

constructed using 1x4 liftarms and standard beams. The pads are

made from cams.

A crank on each side independently drives the front and rear outrigger

on that side. The crank drives a worm gear which then drives a 24

tooth spur gear resulting in 24:1 reduction. An axle on the 24

tooth gear runs the entire length of the chassis and directly drives

the rotation of the driving links of the outriggers. A secondary

linkage below the driving links makes this a 4-bar linkage.

Because the arms are 3 studs apart at one end and only 2 studs apart at

the other, the outrigger arm rotates as it deploys.

Due to a careful selection of geometry, the outriggers are

self-locking. When fully deployed, weight on the foot tends to

rotate the two sets of liftarms together, locking the assembly, rather

than trying to backdrive them. It is this geometry, rather than

the worm gear, that prevents the outriggers from collapsing under

weight.

The outriggers provide a wide base for stability and are

slightly taller than the tires so that all 6 tires are lifted off of

the

ground.

|

Click for an animation of the

outrigger

in motion.

|

|

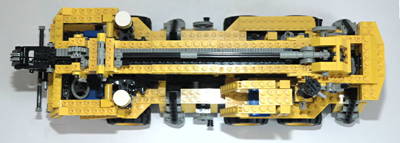

Wheels and Tires

This set uses six of the smaller size 20x30 balloon tires and wheels. |

|