9V Electric

System

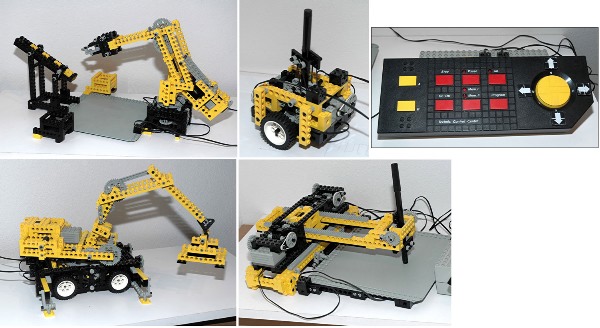

1990 saw the release of a brand new motor system.

The old 4.5V motor and battery box were replaced with new 9V versions.

- The new battery box held 6 AA (LR6) size batteries (1.5V)

in series and was 4x14 studs in area. There was a single

electrical output connection. A rocker switch controlled polarity

to run the motor either forwards of backwards. This is a very

sturdy motor box although if you ever get corrosion inside from the

batteries it will take you a very long time to rebuild it.

- The new 9V motor was 4x5 studs in area with a single axle

output. Typically a small toothed bushing was used as a pulley on

this output. This is a high speed motor which requires

significant gear reduction to be used for any useful function.

- A new blue belt was typically used as the main drive system

from the motor. Use of a belt allowed the motor to slip rather

than stall if too much torque was applied. Unlike the old rubber

bands, this belt was not made from rubber but some other type of

elastomer which does not degrade over time when installed under

tension. There was also a smaller white belt.

- The new electrical wires (not shown) used a 2x2 plate with

4 contacts. This connector was specifically designed to make sure

that it could never be shorted. The polarity of the motor could

be reversed by rotating the connector 90 degrees.

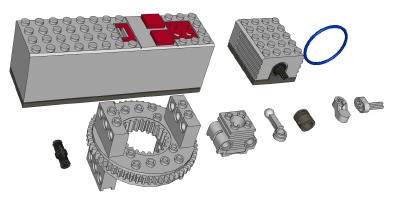

Modified Friction Pin

The new black friction pin looked very similar to the old. The

major difference is that a longitudinal slot was added which makes the

pin compress slightly when installed. This makes it much easier to remove than the old

variety. This part would become a staple of Technic construction

up to the present day. There are probably more of this part in

Technic sets than any other.

Turntable

A new turntable was introduced as a vast improvement over the old 4x4

circular variety. It was a large diameter and featured both an

internal (24 tooth) and external (56 tooth) ring gear so it could be

driven by gear systems

on the model. The internal ring gear was attached to the lower

half of the turntable, and the external ring gear to the upper.

The internal ring gear was the same size as a 24

tooth spur which fit perfectly inside. With 6 pin holes on the

top and the bottom, it

could support significant weight. It was used on many of the

larger sets for many years.

Engine

Elements

While the old reciprocating engines had a unique 2x2 piston part, the

rest of the engine was made with standard parts. That changed in

1990 with the introduction of a whole new engine system comprised of

parts designed to work together. This system would be used on a

wide variety of sets for decades.

- A 2x2 cylinder block featured a round bore and simulated

cooling fins on the exterior Two pin holes on either end were

used to mount it.

- A round piston fit snugly inside the bore of the cylinder

and had a spherical ball receptacle on the lower end.

- The connecting rod has a ball joint at the top and a hole

at the bottom. The rod was offset 1/2 stud width so that opposing

pistons could be aligned in the same plane, something which was not

possible with the old engines.

- A crankshaft end piece had an axle on one end and an axle

recess offset 1/2 stud on the other end. This allowed a

crankshaft to be constructed with a 1 stud stroke.

- A central crankshaft piece had an axle recess on either end

offset one stud with. It was used for engines with more than two

cylinders requiring a longer crankshaft.

Tire

A new 20x30 solid foam balloon tire was introduced which fit on the

existing 20x30 wheel.

|

|