1st

Model: Race Car

|

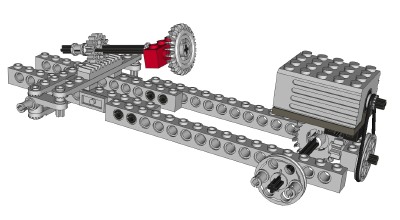

This

rather

sleek looking race car features rack and pinion steering and a

motorized rear axle. The "body" is actually similar is style to

the 8865 Test Car.

The front wheels can be steered using a gear at the driver's

position. The wheel drives a 16 tooth pinion.

The pinion drives

the steering rack. The

steering mechanism itself uses

steering arms and toothed links.

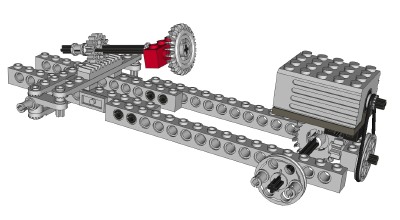

The motor connects to a pulley via a belt as shown in the computer

image. The belt drives the solid rear axle through a set of 8 and 24

tooth gears. Since the total reduction is only about 9:1, the

high speed motor drives the car pretty fast.

|

Click to download the LDraw

file of this model.

Model by Benjamin Wendl

Click for an animation of

the

steering in motion.

Click for an animation car driving.

|

2nd

Model: Helicopter

|

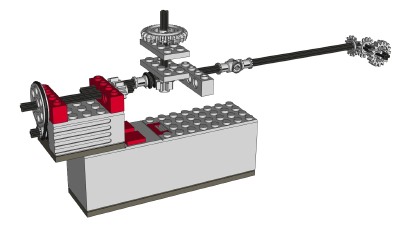

This

mid-sized

helicopter seems to clearly be a model of the Sikorsky S-64

Skycrane. Like the S-64, its wide landing gear allows it to lift

full size cargo containers. In this case, the cargo is the

battery box which can be detached from the helicopter.

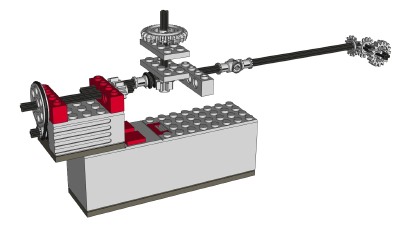

The main and tail rotors are motorized as shown in the computer

image. The motor drives a pulley wheel through a belt.

After a pair of 8 tooth spur gears, a worm gear drives the main rotor

with a reduction of about 24:1. The tail rotor works in parallel

following a set of 14 tooth bevel gears, and is geared to move 8 times

faster than the main.

|

Click to download the LDraw

file of this model.

Model by Benjamin Wendl

Click for an animation of

the rotors in motion.

|

3rd

Model: Tow Truck

|

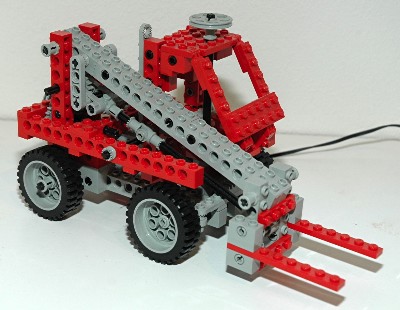

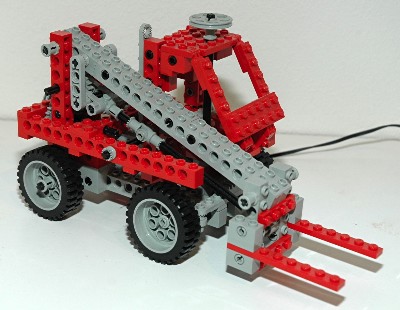

This

small

tow truck features rack and pinion steering and a motorized rear

winch.

The front wheels can be steered using an overhead "hand of god"

wheel. The

wheel drives a pair of 24 tooth gears which drive a

pinion. The pinion drives the steering rack. The

steering mechanism itself uses

steering arms and toothed links.

The motor drives an 8 tooth spur gear which, in turn, drives a 24 tooth

crown. The next stage is also 8:24. Finally, a belt drives

the final stage which is connected to a string and powers the

winch. Final gear reduction is about 27:1.

|

|

4th

Model: Forklift

|

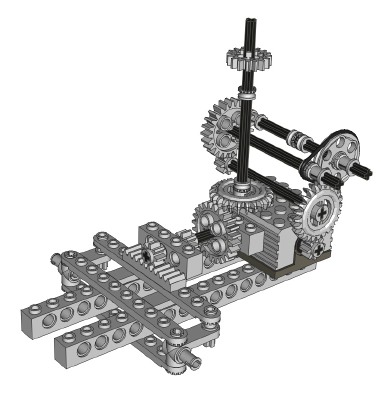

This

forklift

is very well done and features rack and pinion steering and

motorized forks. The construction method is quite complicated and

asymmetric. The construction techniques are similar to those

found in the 8851 excavator.

The front wheels can be steered using an overhead "hand of god"

wheel. The wheel drives a pair of 8 tooth pinions through a set

of 14 tooth bevel gears. The pinions drive the steering rack. The

steering mechanism itself uses

steering arms and toothed links.

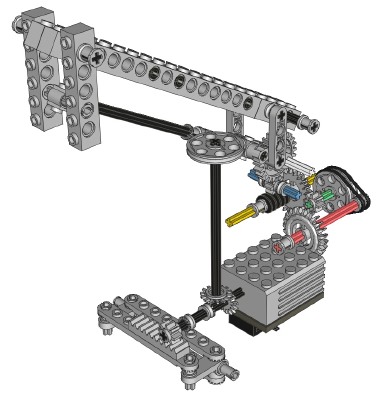

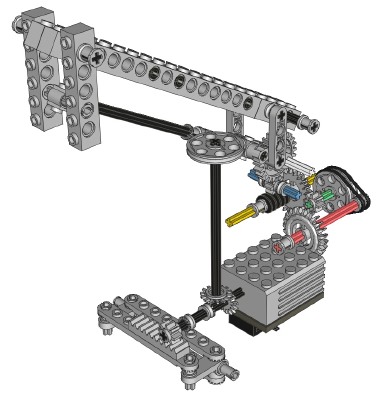

The motorized forklift uses one of the more convoluted gear trains and

among the higher gear reductions in Technic. The computer

image at the right is color coded for convenience. First, an 8

tooth spur gear on the motor drives a 24 tooth crown (red axle).

Next, a pair of belts drive through pulley wheels (green axle).

Following that are another set of 8 and 24 tooth gears (yellow

axle). On the yellow axle is a worm gear which drives an 8 tooth

spur gear on the blue axle. The white axle has the final 24 tooth

gear which also drives a pair of liftarms. The liftarms make up

part of a 4 bar linkage which lifts the forks and keeps them parallel

to the ground. Assuming the pulleys are about 3:1, the final gear

reduction is (24:8 x 3:1 x 24:8 x 8:1 x 24:8) 648:1. It takes

about 5 seconds to lift the forks.

The use of a worm gear results in a system which cannot be backdriven

(because the axial friction is higher than the

backdriving torque due to the screw pitch angle) which allows the forks

to be supported so that they do not fall under their own weight.

|

Click to download the LDraw

file of this model.

Model by Benjamin Wendl

Click for an animation of

the

steering in motion.

Click for an animation of

the forks lifting. |