Tamiya Flakpanzer Gepard Project

Page 5: Building the Turret

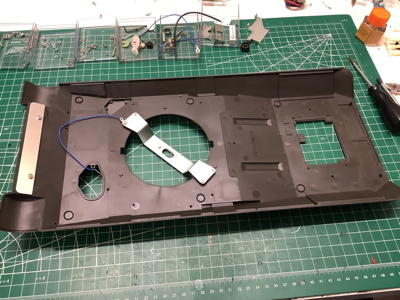

The bracket shown on the left serves as the mounting point and rotation

axis for the turret. The bottom of the turret has a protrusion

which fits into the slot and then rotates 1/6 turn (hex) to be retained

by the spring clip. This bracket also serves as a grounding point

for the turret electrical system. The picture on the right shows

it mounted to the underside of the hull along with the blue ground wire.

Here I've attached the large number of detail parts to the top of the

hull. The real Gepard has a small diesel engine installed in the

front left of the hull which is used to run generators to drive the

turret traverse, gun elevation, and radar systems. The channel you

see running along the left side is the exhaust system for that engine

which vents through the back. The large hatch on the front left is

for accessing this engine. The much larger hatch on the back is

for accessing the main drive engine. The hatch on the front right

is for the driver and contains the driver's periscopes as well as an

extra armored panel over the hatch. The model uses this hatch to

access the main power switch.

These pictures show the buildup of detail parts on the main turret

housing. The picture on the left is a single molded part. On

the right I've added smoke canisters, antenna supports, lift points,

hatches, and periscopes. The hatch even has a clever working latch

system. Everything is extremely detailed in typical Tamiya

quality, though this is even more impressive given the year of

release. Zoom in on the left picture and look at the weld beads

and bolt heads.

This is the motor used to drive the rear mounted search radar. It

has 3 stages of reduction: one at the motor pinion, another at a right

angle into the radar housing, and a final large reduction using a worm

gear. The radar dish itself is only pressed lightly onto the final

shaft so it can slip if it becomes blocked. This motor was

intended to run on only 3V from a pair of C batteries, but even so it

rotates very quickly. At first I thought it was way too fast for

scale, but then I saw some videos of the real thing which rotates at

about 60 rpm.

Here is the MPDR-12 Doppler search radar which is used to acquire

targets. It may look like only a couple of parts, but there are 13

parts here even before the mechanism for turning the radar.

The picture on the left shown how the motor drive system for the search

radar is installed into the hatch on the rear of the turret. On

the right you can see the hatch installed onto the turret. Note

that the radar can fold down to lower the profile of the vehicle for

transport. It raises when in use. This rotation is purely

manual in the model; no motorization. This rear hatch is hinged so

it can be opened to maintain the mechanism.

This little brush system is intended to allow power to pass from the

hull to the turret without tangling any wires, thus allowing 360 degree

rotation. In practice, it didn't quite work out. The white

wire has to be sandwiched between a plastic shaft and a metal collar,

but there is no slot for the wire so it ends up getting pinched very

tightly. After only a short while, my wire severed. It can

never be reattached because the collar can't be removed without

destroying the part. Luckily, I was already planning to use a

speed controlled electrical system for the turret anyway or I would have

been very upset about this failure. The picture on the right

shows the many stages of reduction between the motor and the

output. The initial stages are plastic because the torque is low,

but the final stages are metal.

The picture on the left shows the turret traverse mechanism. The

motor

is protruding at the upper right and it drives the crank at the upper

center. At the same time, it drives the crank at the lower left at

a

1:1 rotation with the turret. The little tab on the crank serves

to lift

the barrels up as the turret rotates. The barrel elevation cannot

be

controlled independently. The picture on the right shows this

system installed into the turret. The turret and radar are wired

together on the same circuit so they move together, thus requiring only 3

channels to operate the model.

The picture on the left is one of the Oerlikon 35mm cannons which

consists of 22 parts, some of them very tiny. The guns press onto

the elevation shaft with a friction fit rubber washer which makes them a

bit wobbly but easy to adjust and/or remove. The picture on the

left is the tracking radar which is gimballed on two axes (no

motorization, manual elevation and azimuth).

©2021 Eric Albrecht