Tamiya Flakpanzer Gepard Project

Page 4: Building the Gearbox

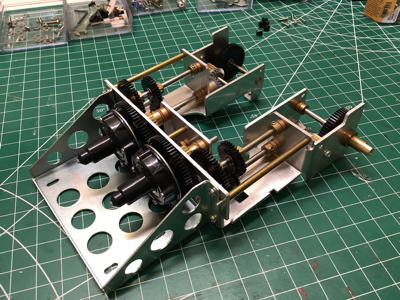

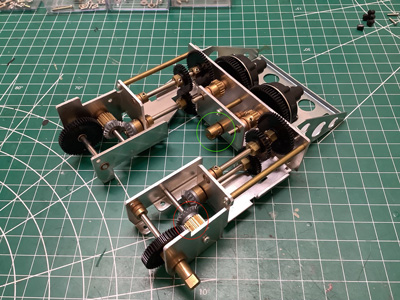

The gearbox comes out of the packaging already built as shown.

There are several interesting things to note. The right and left

side gear trains are mirrored but otherwise identical. The two

black spur gears mate together making them rotate in opposite

directions. The gears range from molded plastic to sintered metal

to machined brass. Most of the gear pairs match brass to plastic

with the exception of the bevel gears which are both metal (I hesitate

to use the word steel). The motor input location can be seen in

the right hand picture circled in green. There are no bearings in

this gearbox. In general, the gears are locked to the shafts with

set screws so that the shafts rotate with the gears. The shafts

fit into brass bushings pressed into the sheet metal housing. All

of these sliding joints need to be lightly lubricated for the gearbox to

run smoothly. It is not tolerant of dirt and grit getting

into it. Axial motion of the shafts is prevented with brass

collars and cork washers. There are five total gear stages which

progress as described below:

- Pinion/Spur = 15:64

- Stage 1 = 15:50

- Stage 2 = 36:36

- Stage 3 = 20:20

- Stage 4 = 20:50

- Overall = 35.6:1

Note that two of the gear stages are 1:1 and therefore provide no

reduction. The overall ratio of 35.6:1 is not very much reduction,

but keep in mind that this was originally intended to run on 6V. I

did have one repeating problem with this gearbox. The two gears

circled in red on the right connect the 3rd and 4th gear stages and are

meant to rotate together but there is no mechanical connection between

them. They rely on the friction of a light press fit to

work. I found that it didn't take much resistance for this joint

to begin slipping which effectively stops the tank. I separated

them, roughed up the mating surfaces, then pressed them back

together. That seemed to do the job and I've had no further

problems.

I didn't tear down the entire gearbox, but I was compelled to take apart

the clutch and see how it worked. An exploded view of the parts

is shown on the left and a cross section from the Leopard A4 manual

(which uses the same gearbox) is shown on the right. The large

black gear is the spur gear which is driven by the motor directly from

the pinion so it is always spinning. I've circled the areas which

are the key to the whole thing working. You may have to zoom in on

the picture on the left to see the flat spot on the brass collar and

on the metal disc that I'll call the rotor. The flat spot makes

these rotate together. The rotor has radial grooves on it to help

it grip the cork stators. When the spring is engaged (which is the

default), the rotor is locked between the cork stators which are in

turn locked to the annular metal plates on either side. Pressing

the metal button at the end of the clutch housing compresses the spring

as the housing slides aft. This releases the clutch by

disconnecting the spur gear from the shaft. This is a really

clever system which allows a single motor to drive both tracks while

disengaging either side with the clutch for steering. Note that

the clutch can be partially slipped which allows gentle turning.

Zero turn radius (tracks turning in opposite direction) is not possible

with this system though. One last little detail relates to the

brake shown on the bottom right. Simply releasing one side would

disconnect that track from the motor, but it would still be able to

freewheel which would not be enough to allow for sharp turning.

The whole shaft slides back when the clutch housing is pressed which

grounds the shaft to the gearbox housing effectively forcing it to

stop. There was a lot of engineering put into this gearbox.

Not bad for a guy (Dr. Taki) who had only recently transferred from the accounting

department.

This view shows how the motor pinion drives the clutch gears. The

left hand gear is driven directly while the right hand gear is driven

from the left.

This little mechanism converts servo motion into steering

controls. Those old servos didn't have much torque so it was

important for this mechanism to offer a lot of mechanical

advantage. The very long crank arm shown on the right is driven by

the servo horn. This crank rotates the square drive socket shown

on the left. This socket presses the left or right cam

backward. These cams contact the buttons at the end of the

mechanical clutches, disengaging them.

This is a close-up view showing the operation of the steering

system. The picture on the left shows the system at neutral with

both clutches engaged. The gap between the cams and the clutch

buttons can be seen through the square windows and must be calibrated to

be as small as possible. There should be no drag when driving

straight, but very little servo motion should be required to engage the

system. The picture on the right shows a right hand turn.

The square window on the right shows the cam pressing

on the clutch and disengaging it. This is a contact point with

relative motion so it would eventually wear out if driven often.

Now the gearbox has been installed into the chassis. The only

protruding areas are the shafts which will connect to the drive

sprockets.

The motor is mated to the gearbox only after the gearbox has been

installed into the chassis. The vintage silver can motor is shown

on the left. The slotted metal collar on the motor drives an

identical collar on the gearbox through a plastic key. The tabs on

the key are rotated 90 degrees on one side compared to the other.

This allows the key to slide on two axes so that the joint can take up

any misalignment between the motor and the gearbox as the motor

spins. The misalignment is visually noticeable and this system

seems to compensate very well. Note that the motor is wired

through a switch on the back panel. This is not really needed for

the RC version, but if you wired it to simply drive straight ahead then

this would be the power switch.

Now the tracks can be fit to the chassis. On

the left you can see how the idler sprocket spins freely on a brass

bushing on the front axle. Again, note that there are no bearings

anywhere on this model. The front axle can be adjusted forward

or back to tension the tracks.

©2021 Eric Albrecht