Tamiya Flakpanzer Gepard Project

Page 3: Building the Suspension

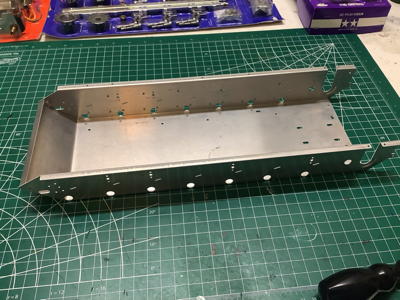

Here is the formed aluminum sheet metal chassis which forms the backbone

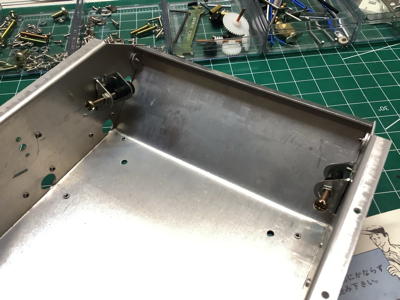

of the tank assembly. The picture on the right shows a pair of

brackets which support adjusting screws. These screws will be used

to push the front axle forward which will serve to tension the tracks

using the front sprockets.

These cast parts are the suspension trailing arms. The slot on the

inner end connects to the rectangular torsion bar (a simple steel

plate) shown which supports the weight of the vehicle and allows

articulation over obstacles and terrain features. The serrations

you see on the spindles are all that holds the road wheels on. A

flexible rubber bushing will be pushed over these serrations and act

both as a wheel bearing and a retainer. The picture on the right

shows the seven arms installed on one side of the chassis. Each

has a bump stop which limits the maximum possible travel.

These pictures show how the torsion bars work. The picture on the

left shows the brackets bolted to the chassis which serve as end locks

for the torsion bars. The torsion bars insert into the X-shaped

recesses. The reason they are X-shaped is so the same part can be

used on both sides. The right hand picture shows all of the

torsion bars installed. Note that the left and right side are

offset slightly in the longitudinal direction.

Here we see the parts that make up the faux shock absorbers. These

are just for show since the piston just slides freely within the

cylinder. On the real tank these would be filled with fluid and

act as dampers. On the right you can see the installed dampers as

well as the 4 return rollers.

Here are the parts to build a road wheel. Each of the seven road

wheels per side is actually made up of dual wheels with a gap between

for the track guide. Each is comprised of two wheels and two

rubber tires as shown. The picture on the right shows the

completed suspension. The chassis can now roll freely.

©2021 Eric Albrecht