Features

|

|

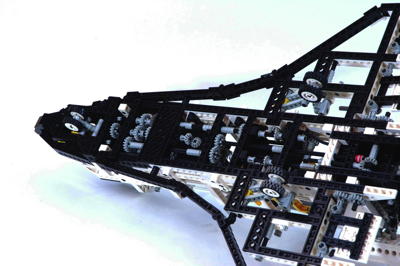

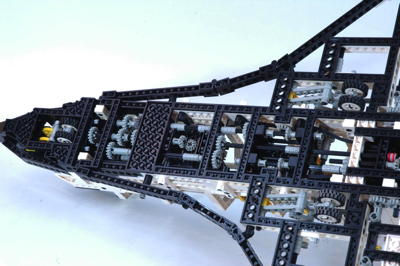

Mechanical Functions

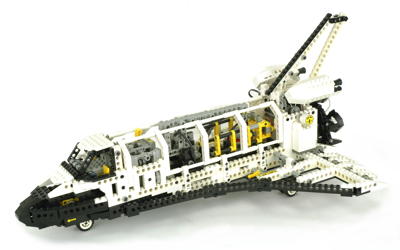

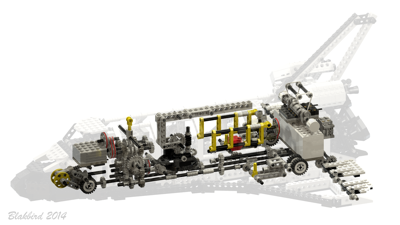

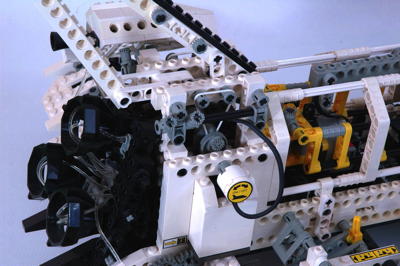

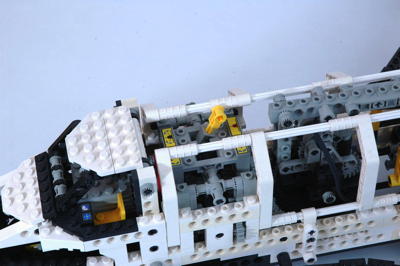

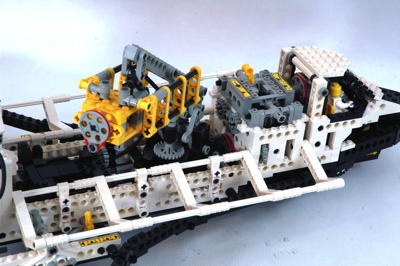

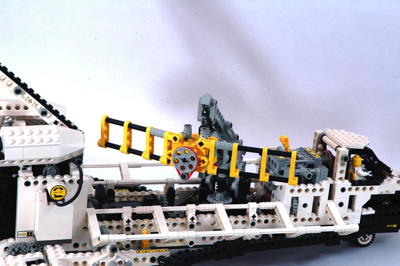

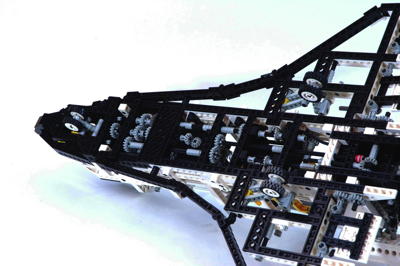

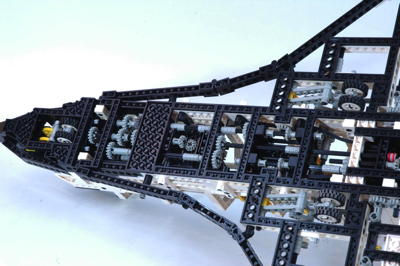

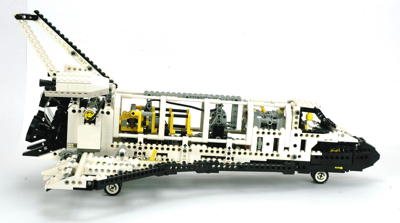

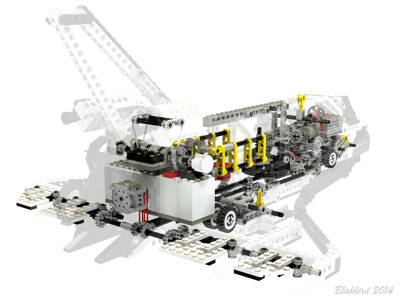

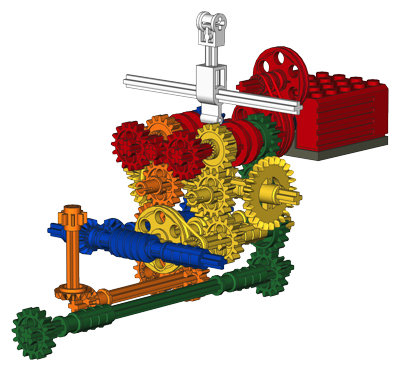

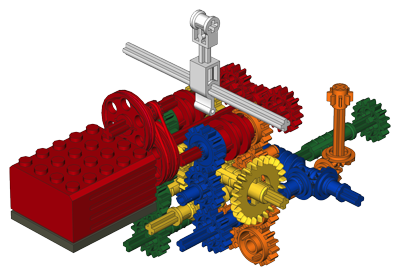

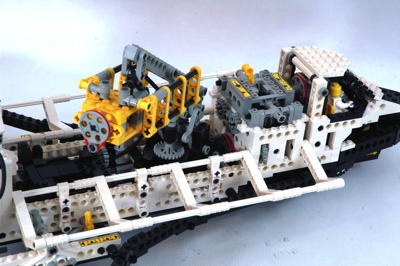

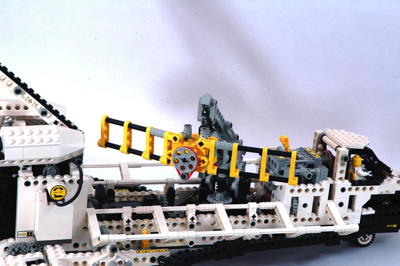

If there was any lingering doubt about what it is that makes 8480 so

great, these images should clear up the confusion nicely (make sure to

look at the full size versions). You can see that the insides of

the model are positively packed with mechanical and electrical

functions. In fact, the gearing is so dense that it is difficult

to see what is happening without dissecting the functions individually. This is precisely what will follow below.

|

|

|

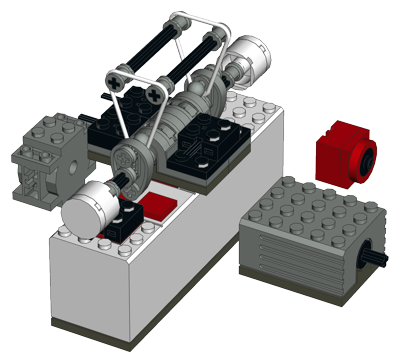

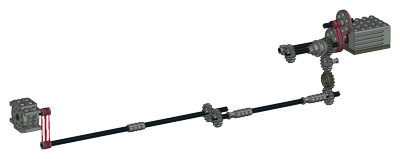

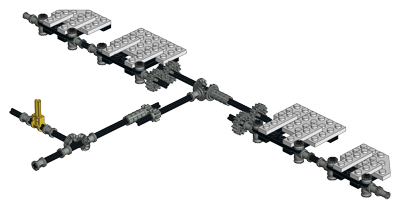

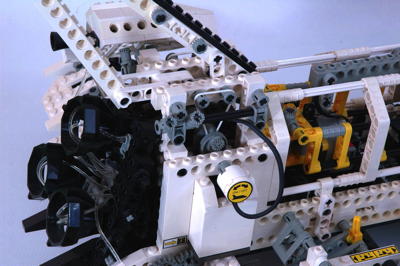

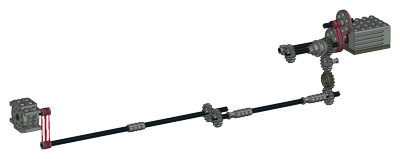

Electrical System

8480 features by far the most complex electrical system up to that time

with two motors, two switches, and a fiber optic system. A 9V

(6xAA) battery box is tucked away in the aft fuselage where it blends in

nicely and yet remains easily accessible. The battery output goes

to a 2x4 electrical plate which spans a pair of pole reversers.

These are used as both on-off switches and as a means to reverse the

polarity of the motors. An axle protruding from each switch is

accessible from outside the model and centered by a rubber band overhead

as seen in the computer image. Simply turn the round knob and a

motor runs as long as the knob is held. Release the knob and the

motor shuts down. Turn the knob the other direction and the motor

reverses. The knob on one side controls the main 9V motor which

runs the gearbox. The knob on the other side controls the micro

motor which is connected to the satellite. The fiber optic

box is wired to the same switch as the main motor, so it is illuminated

(but not turning) any time the main motor is running, regardless of direction.

The motors in the computer image are shown in a false location for ease

of display. They are actually located at the opposite end of the

model from the battery box and connected by very long wires which must

be painstakingly routed through the lower fuselage. The main motor

is nestled between the astronauts' seats.

|

|

|

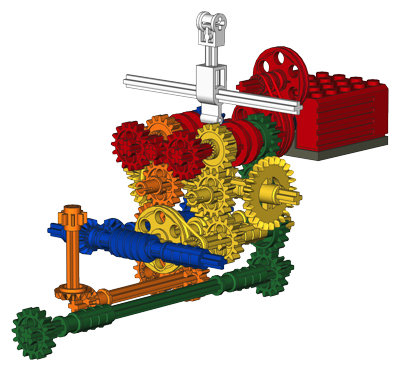

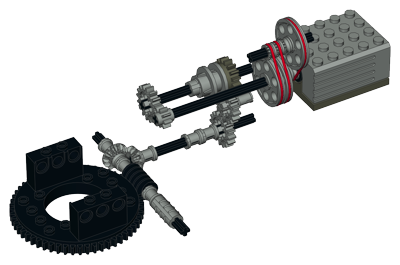

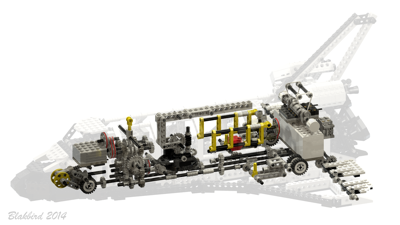

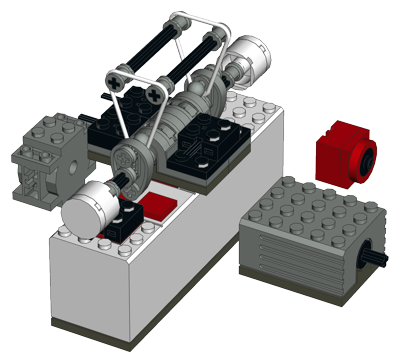

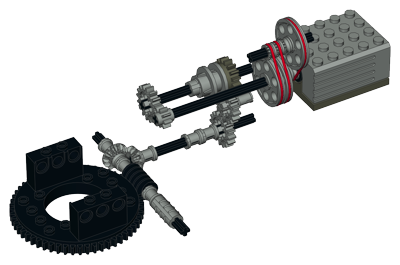

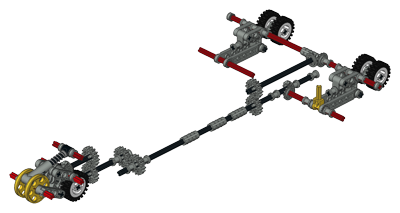

Gearbox

The heart of the model is a 4 position gearbox. It uses the same basic principles as the pioneering gearbox in 8880,

but instead of being used to change gear ratios it is used to connect a

single input motor to one of four different output functions.

The first photograph shows the shift lever and gate with the 4

positions. Each function is marked with a sticker. As the

lever is moved through the H-shaped gate, one

or the other of the two driving rings is forced into position.

Note that only one driving ring can be engaged at a time. Passing

through the center of the H returns the opposite ring to center.

Whereas 8880 had a custom shift lever and mounting plate, the shuttle

uses a new pair of shift gates and lever which would become the standard

for the immediate future.

The driving ring is the key to everything. It slides over the

ridged axle joiner. Small tabs on the driving ring allow

it to lock along these ridges, but still slide with some extra

force. The driving ring grips the longitudinal grooves on the

axle joiner causing them to rotate together. A circumferential

groove in the middle of the ring allows it to be pushed along the axle

joiner in either direction. A set of 4 driving dogs on either end

then mate with a 16 tooth idler gear allowing the idler's rotation to

be either synched with the axle or allowed to spin freely.

The animation shows how the driving rings work to engage and

disengage the clutch/idler gears. The driving ring is shown in

red. The

lower axles are joined with the gray axle joiner. The driving

ring rotates with the axles. At first, the driving ring is

disengaged so both the dark gray and green gears are not driven and

slip on the axle. The driving ring then engages the green gear

and

thus drives the blue gear. Because the driving ring does not use

gear teeth but

rather uses four tapered driving dogs, there is considerable backlash

between the driving ring and the gear. The allows the driving

ring to be engaged even while it and the mating idler gear are turning

at different speeds.

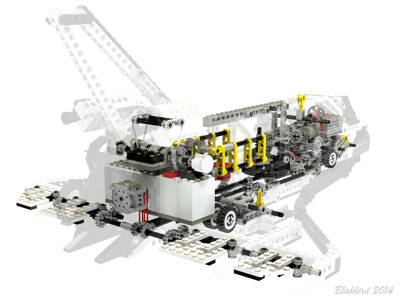

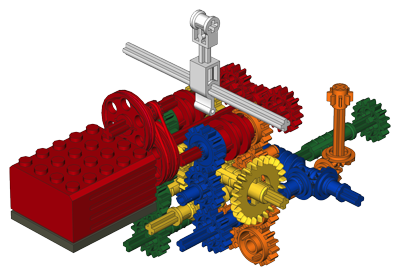

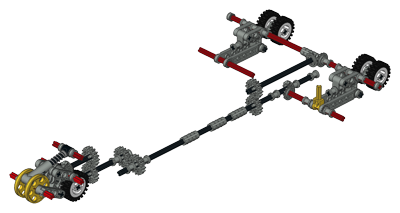

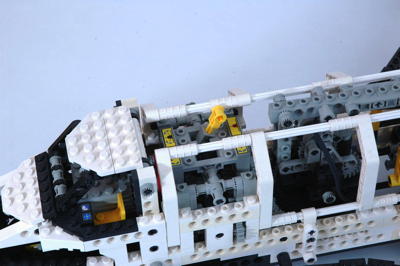

The lower computer images are color coded to show the different

gear paths for each of the 4 functions. Red is the input from the

motor which uses two stages of belts. This both reduces the

motor's speed 9:1 and allows slippage if any of the functions

stalls. The pair of red axles in the upper part of the image are

driven continuously by the motor. The white lever is used to

switch gears. Yellow is the door mechanism, blue turns the crane,

orange lifts the crane, and green runs the fiber optic engine. Any

of these functions individually is pretty complex, but making them all

fit together in such a small space with no interference is the real

achievement.

|

|

|

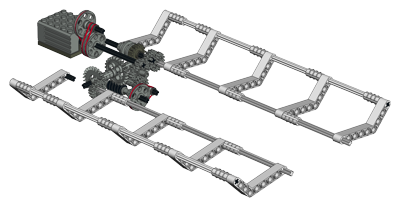

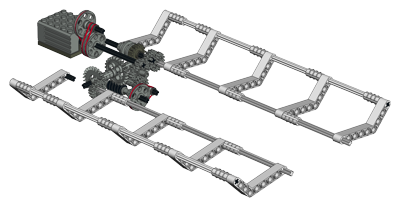

Doors

The cargo bay doors open when driven by the main motor. The doors

are synchronized to move together, although sometimes one or the other

can skip a gear tooth if too much resistance (like a finger) is present.

The computer image shows how the mechanism works. After the

initial belt reduction of the motor, there is still a lot more reduction

to come. The gearbox driving ring passes torque downward through

several levels of the gearbox via 16 tooth idler gears, then uses a belt

to provide another 3:1 reduction. Next a worm gear is used to

mate with a 24 tooth gear mounted laterally. This drives a pair of

crown gears which drive the 16 tooth gears mounted to each door.

The worm gear allows the door to maintain any position without

backdriving. Final reduction from the motor is 3:1 x 3:1 x

16:8 x 3:1 x 24:1 x 16:24 = 864:1 which drives the doors at a very reasonable speed.

Because this function has such a huge gear reduction, the use of the

additional belt further downstream from the motor provides an effective

torque limiting function.

|

Click for an animation of the cargo bay doors in motion. |

|

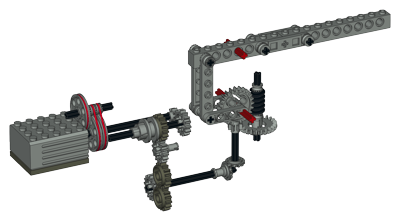

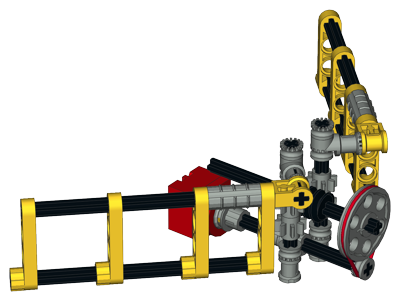

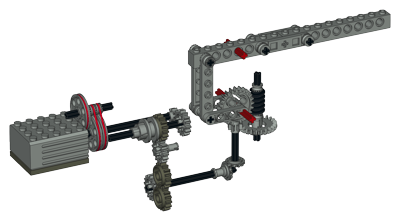

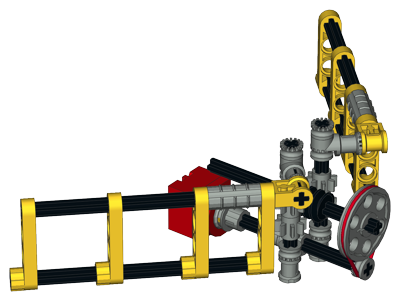

Arm Lift

The Remote Manipulator Arm can raise and lower using the same

motor. Since the arm can both lift and pivot, the lifting function

must pass concentrically through the turntable to the arm. The

whole arm only lifts about 45 degrees at full extension.

The computer image shows the torque path. After the initial belt

reduction of the motor, the gearbox driving ring passes torque downward

through several levels of the gearbox via 16 tooth idler gears. A

set of bevel gears then turns the corner and passes through the

turntable. A further 3:1 reduction happens with spur gears prior

to the worm gear. The vertical worm gear drives a 24 tooth gear

whose axle lifts the arm. It is a little tricky to picture how the

arm mechanism works, so I've color coded the axles which are grounded

to structure in red. The links pivot at these axes resulting in a

4-bar linkage.

Final reduction from the motor is 3:1 x 3:1 x 16:8 x 24:8 x 24:1 = 1296:1

|

Click for an animation of the arm lifting. |

|

Arm Rotation

The Remote Manipulator Arm can also rotate on on a turntable driven by

the same main motor. It is capable of pivoting about 70 degrees

from center in either direction before the wire which runs up the arm to

the satellite becomes taut. There are also a pair of plates which

mechanically limit the rotation at ~90 degrees.

The computer image shows the torque path, the simplest in the

model. After the initial belt

reduction of the motor, the gearbox driving ring passes torque downward

through a level of the gearbox via a 16 tooth idler gear. A set

of bevel gears then turns the corner and drives the turntable with a

worm. Final reduction from the motor is 3:1 x 3:1 x 16:8 x 56:1 = 1008:1

|

Click for an animation of the arm rotating. |

|

Satellite Deployment

The satellite hangs at the end of the arm and is driven by a micro

motor. The output pulley of the micro motor drives another pulley

through a 3:1 reduction (keep in mind the micro motor turns very slowly

to begin with). A worm gear then drives a pair of 8 tooth pinions

directly connected to the solar arrays of the satellite. Final

reduction is 3:1 x 8:1 = 24:1.

This is the slowest function of the model. Full deployment of the solar arrays takes about 10 seconds.

Because this function uses a separate motor not driven through the

gearbox and powered by a separate switch, it can be run simultaneously

with other functions. For example, it makes sense to have the solar arrays opening as the arm rotates.

|

Click for an animation of the satellite in motion. |

|

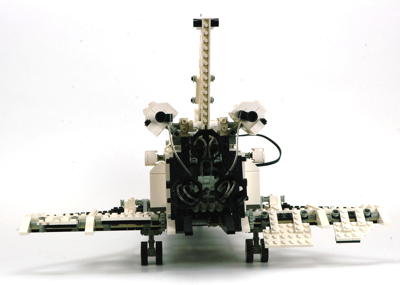

Engines

The engines use the new fiber optic system. While power is

available to the lights inside the unit any time the main motor is in

use, the unit only sequences the lights when the function is engaged at

the gearbox. After the initial belt reduction of the motor, the

driving ring passes torque downward

through several levels of the gearbox via 16 tooth idler gears before

making the long journey to the rear of the vehicle. A final 1:1

system of belts rotates the

fiber optic unit. Final reduction from the motor is 3:1 x 3:1

x 16:8 = 18:1 which drives the engines very quickly.

The fiber optics are not very bright and are certainly best appreciated

in the dark, though they are certainly also visible in the daylight.

From this angle you can see the 3 unique engine parts used for the

shuttle's main engines tilted slightly upwards. You can also see

the boosters on either side of the vertical tail.

|

Click for an animation of the engines in motion. |

|

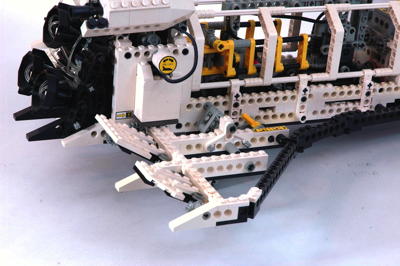

Landing Gear

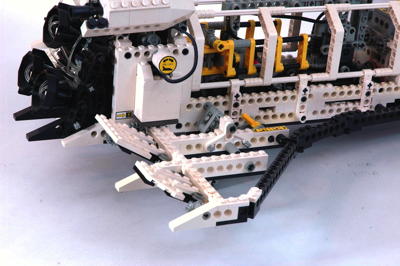

Although it is not motor driven, the landing gear is probably the most

mechanically complex feature of the model. The input is a yellow

lever on the port wing, but the spring which holds the whole system

either up or down is way up in the nose wheel well. The images at

the bottom show the gear in both the up and down positions. Note

that on this model even when the gear is up it still protrudes slightly

from the bottom of the vehicle and therefore still provides

support. When extended, the gear holds the vehicle up higher and

with a slight nose down angle, just like the real shuttle.

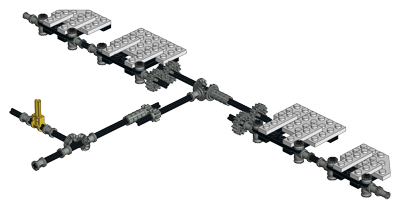

The computer image color codes all the axles which are supported by

structure in red as an aid to understanding the mechanism. The

spring in the nose gear passes over center and therefore holds the gear

against the stops in either the up or down position. The up stop

is a pair of 3L dark grey axle above the main gear, and the down stop is within the nose gear linkage.

The yellow lever rotates a lateral axle which then drives a longitudinal

axle running the length of the vehicle through a set of bevel

gears. At the aft end, a lateral axle drives the links which lower

the main gear. At the forward end, a more complicated 4-bar

linkage pivots the nose gear down. Both gear lock in such a way

when deployed that the weight of the model is transmitted directly into

structure and not through the gear train. It is a mechanism which

must really be seen in motion to be fully appreciated.

|

Click for an animation of the landing gear in motion. |

|

Ailerons

Last but least are the functional elevons. The elevons in the real

shuttle act in two different but interconnected ways. As

ailerons, they move in opposite directions on each wing for roll

control. As elevators, they move in the same direction on each

wing for pitch control. The elevons on the model function only as

ailerons.

A yellow lever on the starboard wing drives the ailerons via a 1:1

linkage as shown in the computer image. Care must be taken while

building to get the gears synchronized so all the control surfaces are level at the same time.

|

Click for an animation of the ailerons in motion. |