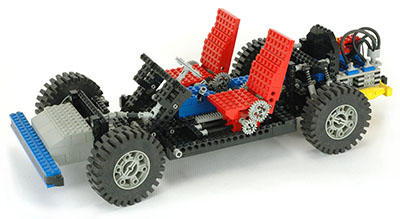

Differential

Gear

A specialized differential gear was introduced. The

ring gear, which has 28 teeth, can act as either a spur gear or a crown

gear due to the tooth profile (like the crown gear). This part is

made to be used in conjunction with 3 of the new 14 tooth bevel

gears. One bevel gear goes on each side attached to an axle, and

a third acts as a planet gear and rides on a pin in the cage. The

assembly acts like a real differential in every way: wheels can turn at

different speeds or together, wheels turn opposite directions if the

ring gear is fixed, and one wheel drives at double speed if the other

is held.

The new 14 tooth bevel gears were the first gears LEGO®

made which were purpose-designed to work on perpendicular axes.

The gear is only 1/2 stud thick and the teeth do not have any back iron

(webbing between the teeth), so it is a bit weak, but future iterations

would correct this.

Shock

Absorber

The shock absorber was an important step. Finally, models could

have real suspension. This part was eventually used for other

purposes, including holding mechanisms over center.

The shock absorber consists of a telescoping mechanism inset with a

helical compression spring. The spring is quite stiff compared

with the weight of parts it typically supports. The shock bottoms

before the spring reaches solid height.

Pulley

The new pulley is smaller than the previous, and has a nice round

groove for driving belts or rubber bands. It is also only 1/2

stud thick, so it fits in smaller spaces.

Plate

The new 3x2 plate with a centered hole on one end can be used to

support axles or pins, and is a way to align studded construction with

Technic beam holes, which are located halfway between the studs.

|

|