Features

|

|

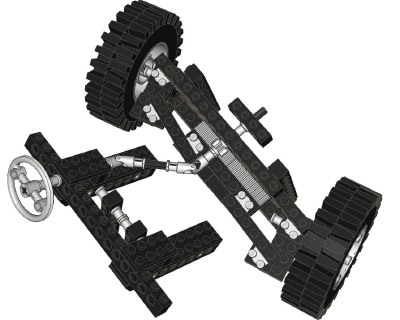

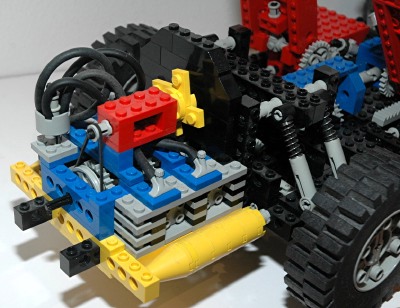

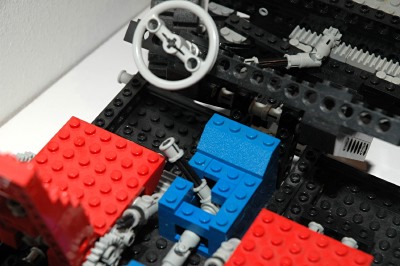

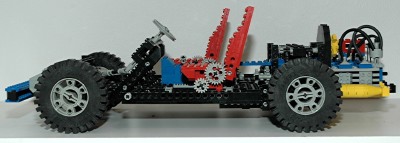

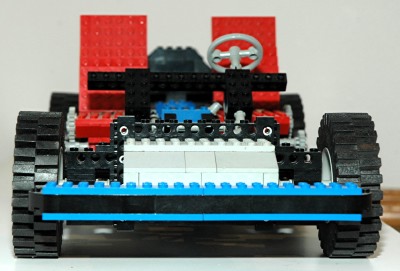

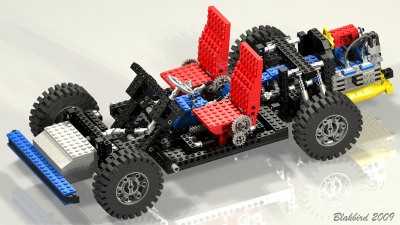

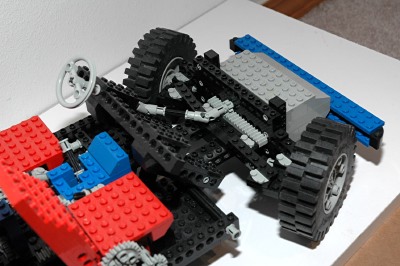

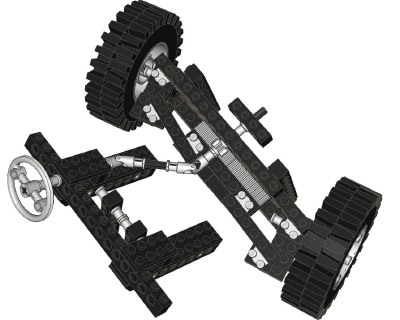

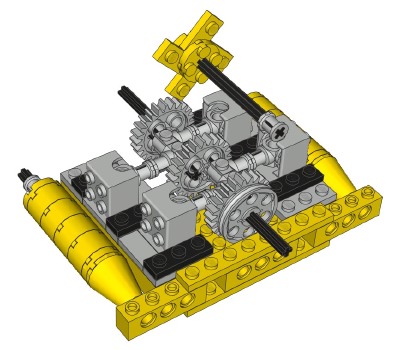

Steering

The front wheels can be steered using a wheel at the driver's

position. As can be seen in the computer generated image, the

wheel drives an axle connected to an 8 tooth pinion gear via a

pair of universal joints. The pinion drives a pair of

racks.

The racks use plates to

attach to the arms of the steering mechanism. The

steering mechanism itself uses 6

traditional 2x2 swivels with 2 pair allowing rotation of the wheels

about the vertical axis and another pair acting as steering arms

attached to the rack gear. Simple axles allow the wheels to

rotate freely.

This is the first Technic set in which the steering employs the

Ackerman Principle. You can see in the images that the tie rod

attachments are not directly behind the kingpins, but are one stud

inboard. The result of this is that the wheel on the inside of

the turn is rotated more sharply than the wheel on the outside, which

is exactly what is required for a turning in a proper circle without

skidding.

|

Click for an animation of the

steering in motion.

|

|

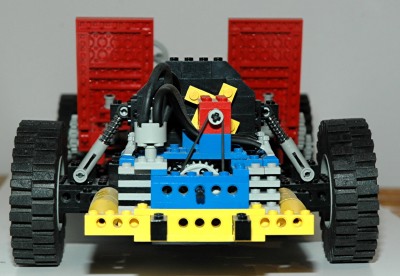

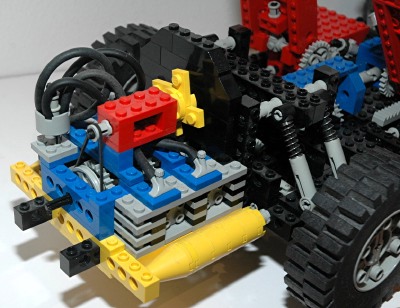

Engine and

Transmission

This set features a rear mounted 4-cylinder horizontally opposed

engine, similar to a "boxer" engine but with one crank pin per pair of

opposing cylinders.

The engine uses the offset axle holes of the 24 tooth gears to make a

crankshaft. Connectors placed end to end and clocked 90°

form rods which connect to 4 specialized 2x2 square pistons. The

"cylinders" are actually square. A belt on the rear of the

engine drives a fan.

The engine also has a number of aesthetic features such as cooling fins

(suggesting this engine is air cooled), a distributor, and a pair of

exhaust manifolds. There is also a bulkhead forward of the engine

which may be either a firewall or a radiator.

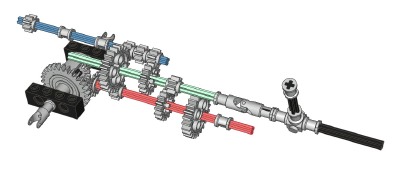

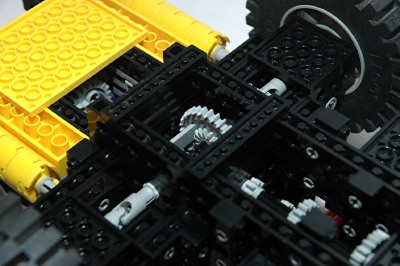

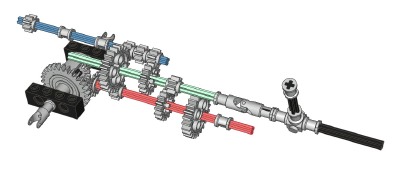

Ahead of the engine is a 3 speed gearbox / transmission (see color

coded computer

image). The green axle and 3 spur gears translate

forward and aft. The blue axle is driven by the engine and mates

with the crankshaft via a 24 tooth gear (not shown). The red axle

mates with the 28 tooth ring gear of the differential via the new 14

tooth bevel gear. In 3rd gear (pictured), the path to the wheels

is (8/24) x (24/8) x (8/24) x (28/14) = 1:1.5 (overdrive). In 2nd

gear, (8/24) x (24/8) x (16/16) x (28/14) = 2:1. In 1st gear,

(8/24) x (24/8) x (24/8) x (28/14) = 6:1.

The gearbox is not synchronized in any way, so it is difficult to shift

gears since they tend not to be aligned.

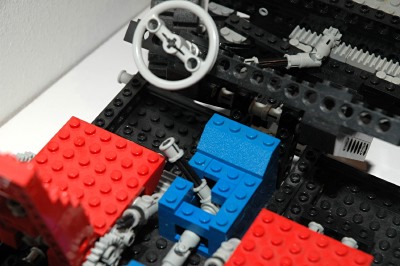

As you can see in the photograph, the shifter only allows two positions

(2nd and 3rd). 1st gear is locked out by blocking it with a

plate. This is due to the fact the gear ratio is so low that the

gear train cannot take the stress if the vehicle is pushed (engine

turns 6 times for every turn of the wheels) and tends to skip. If

the model is motorized (and therefore driven from the engine instead of

the wheels), the shifter is reversed to lock out 3rd instead, since 3rd

gear would tend to stall the electric motor.

|

Click for an animation of the

engine

in motion.

|

|

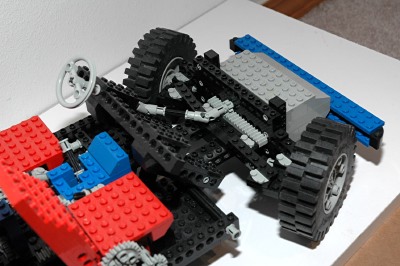

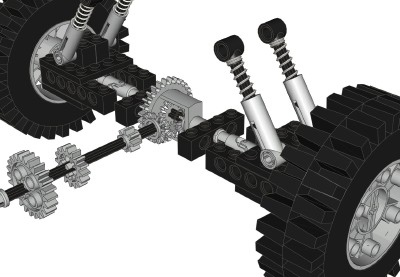

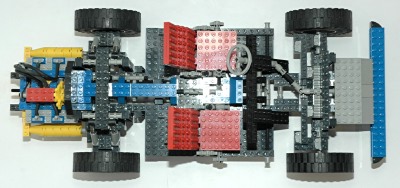

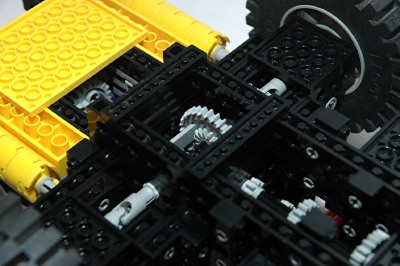

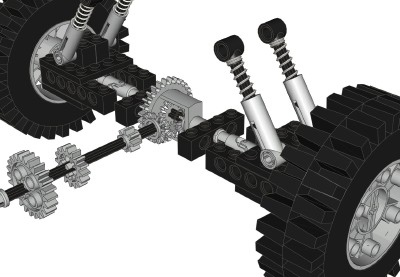

Suspension

This is the first LEGO® set with suspension of any

kind. It is primitive but effective independent rear

suspension. The entire wheel assembly rotates with a cantilevered

lower control arm supported by a pair of new shock absorbers.

This is a swing axle type suspension which results in large

changes in wheel camber as the control arm is raised (see animation).

The wheel is driven through a universal joint. Since there is

only a single u-point, the rotational velocity of the wheel is not

constant, and becomes increasingly erratic at larger angles.

Luckily, the sprng weight of the vehicle is low enough that the control

arm is horizontal under normal load.

|

Click for an animation of the

suspension

in motion.

|

|

Differential

This is the first set with a real differential gear. It

incorporates a built in 28 tooth ring gear which can work either as a

bevel or a spur, similar to the 24 tooth crown gear. It is made

to house 3 of the new 14 tooth bevel gears. One is on each axle,

and one planet gear in the middle allows the axles to turn at different

rates. This addition results in very smooth turns for this model.

|

Click for an animation of the

differential

in motion. |

|

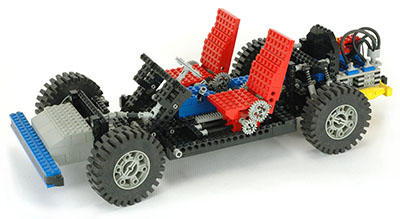

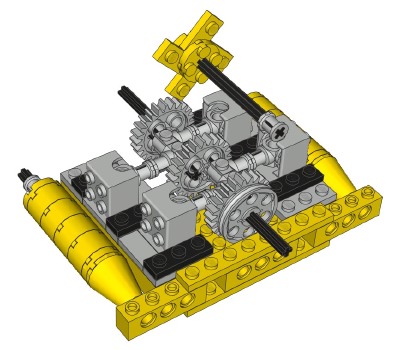

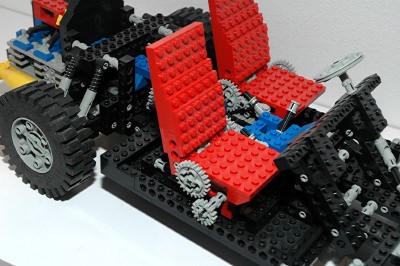

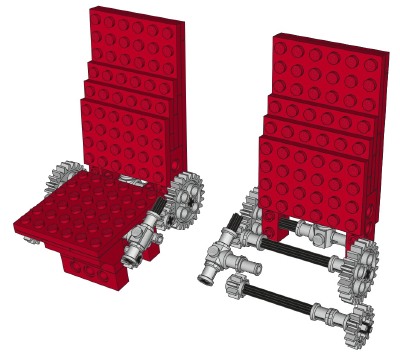

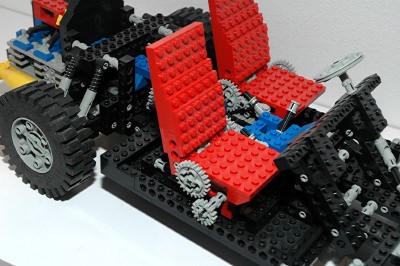

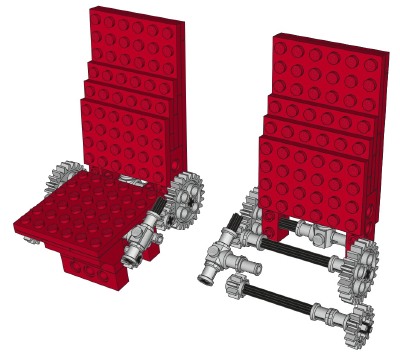

Seats

The bucket seats are among the most technical that LEGO®

ever made. A pair of longitudinal axles support each seat and

allow it to translate forward and back. A rack gear runs parallel

to the axles. A pinion gear attached to the seat can be turned

via a crank, driving the seat forward (see computer image and

animation).

In addition to the ability to adjust the position of the seats, these

seats also can be reclined! A second crank turns a set of 8 and

24 gears, one on the base and one on the seat back. A ratchet and

pawl, spring loaded by a rubber band, keep the seat from falling back

and lock it in any position.

There are no rear seats.

|

Click for an animation of the seats

translating.

Click for an animation of the seats

reclining.

|

|

Wheels and Tires

This set uses four foam 24x43 tires and wheels, the biggest

foam tire that LEGO® made.

|

|