Technical Fundamentals

Gears

Fundamentally, gears are devices which transmit rotational motion from

one axis to another. Certain types of gears may also result in

translational motion. There are dozens of different types of

gears in industry, only a few of which are replicated in LEGO®.

The

existence

of

LEGO® gears actually

predates the

Technic or Expert

Builder lines and goes back to the Samsonite gear wheels of the

1960's. The different types of LEGO® gears and

their basic

function and usage will be explained below.

Gear Ratios

In the simplest case, a set of gears

results in the same rotation speed on both the input and the

output axle. This happens if both gears have the same number

of teeth. However, in most cases gears are used to change the

speed and mechanical advantage between axles. For simple gears

like those used in LEGO®, calculating

this gear ratio is

simply a matter of counting the number of teeth on each gear and

comparing by dividing the number of output teeth by the number of input

teeth. For example, if the input gear has 8 teeth and the output

gear has 24 teeth, then the gear ratio is 24/8 = 3. The standard

nomenclature for this is to use a colon and relate the gear ratio to

one, for example 3:1.

So what does it mean to have a gear ratio of 3:1? Firstly, this

is the ratio of the rotational speeds of the axles. The gear with

fewer teeth always rotates faster, so in this example the 8 tooth gear

rotates 3 times faster than

the 24 tooth gear. Secondly, the ratio of torque is the inverse

of this ratio. In this example, the 8 tooth gear has 3 times less torque than the 24 tooth gear.

When you use gears to make something rotate faster and produce less

torque, it is called "gearing up". You might use this to

protect

downstream components from the high torque of a motor. When you

use gears to make something rotate slower

and produce more torque,

it

is

called

"gearing

down".

You

might use this to lift something

heavy with a small motor or crank. Sometimes you might not gear

up or down, but simply use gears to get torque from one point to

another with no change in speed or torque.

Spur Gears

Spur gears operate on axes which are

parallel. In the animation below, the gray 16 tooth gear on the

green axle is driving the red 24 tooth gear on the yellow axle.

Note that the relative speeds are 3:2 which is the ratio of their

number of teeth (24:16). Note also that the contour of the gear

teeth is not flat. The profile used is called an involute and it allows the gear

teeth to roll against each

other rather than slide which

minimizes

friciton

and

maximizes

efficiency.

Also note that each

axle has two Technic bricks used as bearings for support. In

general, you want at least 2 bearings supporting each axle to balance

the gear tooth loads, although it is possible to use just one axle pin

with reduced efficiency. The closer you can locate the bearing to

the gear (like the black brick), the more efficiently it will provide

support. It is also generally better to locate bearings on either

side of the gear (like the blue bricks) than to put them both on one

side. One side effect of a pair of spur gears is that the output

axle rotates the opposite direction as the input axle, an effect which

can be clearly seen in the animation. Spur gears are the most

common gear type in Technic.

There were some spur gears made before Technic and Expert Builder even

existed in the 1960's and 1970's, but those are not covered by

Technicopedia. They were very large and ranged from 9 to 42 teeth.

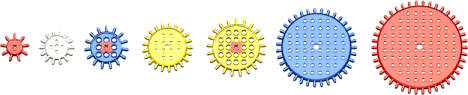

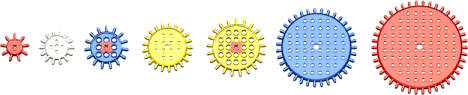

The image below shows the "standard" spur gears. The three shown

in light gray (8 tooth, 24 tooth, and 40 tooth) existed from the

beginning in 1977 and are still in production. The 16 tooth shown

in tan came out in 1979. The 24 tooth shown in dark gray was a

stronger replacement for the older 24 tooth beginning in 1998.

The 24 tooth shown in white is a "clutch" gear which can slip

once a certain torque is exceeded. It is rare and was first seen

in 1997. All of these use the same tooth profile so any spur gear

can be used with any other spur gear. Note also that all tooth

counts are a multiple of 8 which makes gear ratio calculations easy.

Finally, the "double bevel" gears can also be used as spur gears.

These will be explained further in the section on

bevel

gears. They have wider teeth than the regular spur gears and

can handle more torque.

Bevel Gears

Bevel gears operate on axes which are

not parallel. Bevel gears can be made specifically for axles at

virtually any angle, but LEGO

® bevel

gears are all made

for perpendicular axles (90 degrees). In the animation below, the

red gear on the

yellow axle is driving the blue gear on the green axle. The axles

are turning at the same speed because the gears have the same number of

teeth. Bevel gears have complex tooth shapes which also generate

complex forces on the supporting axles. Therefore, it is even

more important than for spur gears that there are proper bearings for

support of the axles. In

general, you want at least 2 bearings supporting each axle to balance

the gear tooth loads, although it is possible to use just one axle pin

with reduced efficiency. The closer you can locate the bearing to

the gear, the more efficiently it will provide

support. In the animation, a special gearbox is used specifically

for this purpose. Spur gears are the second most common gear

type in Technic.

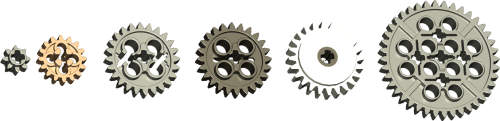

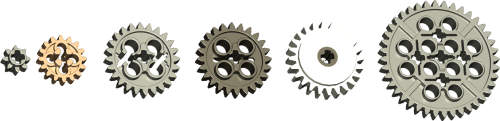

The image below shows the basic bevel gears. The light gray 14

tooth bevel gear was introduced in 1980 and used for many years,

including as part of the old

differential

assembly. In 1995 it was replaced with the 12 tooth bevel gear

shown in tan. This gear has a web between the teeth and it is

therefore much stronger and was used in the newer

differential.

The

uncommon

20

tooth

bevel gear shown in dark gray was

introduced in 1999.

The double bevel gears shown below are so titled because the teeth are

beveled on both sides on the face of the gear. This makes them

somewhat more versatile than the regular bevel gears, but they are also

twice as thick and therefore take up more space. They come in 3

sizes: 12 tooth, 20 tooth, and 36 tooth and began to be introduced in

1999.

Worm Gears

A worm gear (or screw) can be thought

of as a gear with a single tooth. The LEGO

®

worm gear

operates on an axle which is perpendicular to a mating spur gear.

Worm gears have some special properties which make them differ from

other gears. Firstly, they can achieve very high gear reductions

in a single stage. Because the worm gear has only one tooth, the

gear ratio is simply the number of teeth on the mating gear. For

example, a worm gear mated with a 40 tooth spur gear has a ratio of

40:1. Secondly, worm gears have much higher friction (and lower

efficiency) than the other gear types. This is because the face

of the worm gear's tooth is constantly sliding across the teeth of the

mating gear. This friction gets higher the more load is on the

gear. Finally, worm gears cannot (generally) be backdriven.

In the animation below, the worm gear on the green axle is driving the

blue spur gear on the red axle. But if you turn the red axle as

an input, the worm gear will not turn. This is useful for locking

things in place like using a crank to raise and lower a lift

gate.

One final thing to remember about worm gears is that there is force

created which pushes the gear along the axle (green axle in the

animation). Something needs to be used to prevent this motion or

the gear will slide away. One possibility is the yellow gearbox

in the animation.

The worm gear is a little less than 2 studs long. Multiple worm

gears can be put in a row to make a longer screw. It is even

possible to mate a worm gear with the rack gear, although the fit is

not quite right.

Rack Gears

A rack gear is like a spur gear that

has been unrolled to lie flat. It is a means of transforming

rotational motion from the mating spur or pinion gear to translational

motion of the rack. A the pinion rotates, it pushes the rack gear

along as subsequent teeth mesh. There is no gear ratio in the

traditional sense, but the fewer the teeth on the driving gear the more

power will be delivered to the rack. The lateral movement of the

rack is proportional to the number of teeth on the pinion. These

gears are most traditionally used for vehicle steering, but have many

other uses including the extension of a telescoping boom on a crane.

The gear racks range widely in size. The most common size is 4

studs long and attaches to a plate via studs. These can be placed

end to end to create a longer rack. There are a series

of even length racks (8, 10, 12, 14) which have pin holes at the end

and are open underneath so they can slide along studs. There is a

small 2.4 stud length rack with ball joints in the front.

Finally, there is a 13 stud long rack with perpendicular axle joiners

at the end (shown in black).

Differential Gears

Section in work

There have been 3 different differential gear carriers available over

the years. The one shown in light gray was released in 1980 and

was typically used with the old 14 tooth bevel gears. The ring

gear had 28 teeth. It was replaced by the one shown in old dark

gray in 1994. This was typically used with the 12 tooth bevel

gears. The large ring gear had 24 teeth at the large end and 16

teeth at the small end. It also had a recess for a driving

ring. The last version shown in new dark gray was released in

2008. It has a 28 bevel teeth on its ring gear and is used with

the 12 tooth bevel gears.

Driving Rings

The driving ring, in combination with a

pair of idler gears which do not turn with their axle of support, allow

functions to be engaged or disengaged. It slides over the

ridged axle joiner

which we first saw in 1993. Small tabs on the driving ring allow

it to lock along these ridges, but still slide with some extra

force. The driving ring grips the longitudinal grooves on the

axle joiner causing them to rotate together. A circumferential

groove in the middle of the ring allows it to be pushed along the axle

joiner in either direction. A set of 4 driving dogs on either end

then mate with a 16 tooth idler gear allowing the idler's rotation to

be either synched with the axle or allowed to spin freely.

The animation shows how the new driving rings work to engage and

disengage the clutch/idler gears. The driving ring is shown in

red. The

lower axles are joined with the gray axle joiner. The driving

ring rotates with the axles. At first, the driving ring is

disengaged so both the dark gray and green gears are not driven and

slip on the axle. The driving ring then engages the green gear

and

thus drives the blue gear. Because the driving ring does not use

gear teeth but

rather uses four tapered driving dogs, there is considerable backlash

between the driving ring and the gear. The allows the driving

ring to be engaged even while it and the mating idler gear are turning

at different speeds.

A fairly small number of sets have contained these parts over the

years. It is generally used either in a transmission used for

gear changes or in a gearbox used to select between multiple motorized

functions. The driving ring originally always light gray but has

more recently been typically red.

Adjustable Pitch Rotor

Section in work

Ackerman Rack and Pinion Steering

Section in work

Suspension

Section in work

Trailing Arm Suspension

Section in work

Double Wishbone Suspension

Section in work

Many parts can be used to create the

upper and lower control arms including simple beams and liftarms, but

there are also a number of special purpose parts available. The

long Formula-1 style links shown in black first appeared in 2000, but

these appeared in only a few sets. The left dark gray control arm

appeared in 1988 and was replaced with the one on the right in

2008. The arm shown in yellow has appeared in a large number of

sets since 1994.

A number of special hubs have appeared over the years with ball joints

at the king pins and with additional provisions for a steering

attachment. The two in the center were only available in a single

set each, a

Supercar (

8880

and

8865).

The others are easier to find and the yellow one on the left also

supports connecting a driven axle to the hub with a constant velocity

joint.

4-Bar Linkage

Section in work

Engines

Original (Square Piston)

Section in work

Revised (Round Piston)

Section in work