With no body, wheels, or tires included, this kit's

box doesn't take up much space for such a large model. The modest

contents are shown on the right. There is plenty of plastic here,

but the chassis is a formed, anodized, and milled 2.5mm thick aluminum plate.

The built starts, not surprisingly, with Bag 1.

The contents of that bag as shown above and consist mostly of the parts

for the steering, but also the ball bearings for the entire kit.

Note that some bearing are rubber shielded and some are metal

shielded. From what I can tell, the metal shielded bearings are

used in sealed areas for minimum friction, but the rubber shielded

bearings are used on external areas to keep them clean.

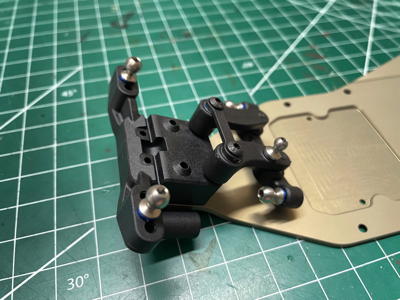

The dual bellcrank steering uses six bearings for

smooth motion. Optional aluminum cranks are available.

Changing the 1mm spacers behind the ball studs will adjust the Ackerman

correction. The cranks are attached to the front upper

suspension bracket as shown on the right. The ball studs are all

installed with

1mm aluminum spacers for vertical adjustability. There are also

multiple holes in the suspension bracket for lateral

adjustability. Different positions would result in different upper

suspension link rotation points which would alter camber response.

While the first set of parts was very small, the parts

contained in Bag 2 are extensive as shown on the left. Parts are

included for the front suspension, bumper, and chassis bracing. I

acquired a set of all Reedy racing electronics to go with this set

including a 6.5T sensored brushless motor, programmable controller, and

aluminum bodied high torque servo. I could have saved a lot of

money using Hobbywing instead, but I felt compelled to keep it in the

Associated family for this one.

The front bulkhead is shown on the left. You can

see the numbers 25 and 30 molded into it along with arrows pointing to

either end. These refer to the kickup angle which can be modified

by flipping the bulkhead over on installation. The vast majority

of the angle comes from the bend in the chassis plate as shown on the

right. The

chassis bend angle is 27.5° and the holes in the bulkhead are drilled

slightly out of plane offering a modification of ±2.5° to that base

value depending on which way it is installed. The default setting

is 25°. Optional aluminum and steel bulkheads add 10g and 30g of

mass, respectively. Note that since the steering cranks are

attached to the

front bracket, they are also angled back with the chassis as shown on

the right.

Next these long side rails are attached which stiffen

the chassis and provide a bit of protection for the electronic

components. The nerf bars on the sides are there to provide some

support for the much wider body in the event of a rollover. Note

the machined pockets in the chassis plate. We'll come back to

those later.

There is no servo saver; the plastic servo horn

attaches directly to the steering servo for maximum control

precision. I suppose the fact that the horn is plastic at least

offers a minimal amount of cushioning compared to metal, although

optional aluminum horns are available. The

steering servo is shown installed at right along with the tiny steering

link. The servo mounts to the plastic side rails, not to the

aluminum chassis plate so it actually floats slightly above the chassis.

The front sway bar is made from a 1.3mm diameter bent

steel wire. Optional thickness of 1.2mm and 1.4mm are available. A collar in the middle will keep it centered in the

front bracket while ball studs on either end will allow short rods to

connect to the lower suspension arms (later). The sway bar is

shown installed in its slot on the right. It will be captured by a top plate later.

There is a milled pocket in the chassis which

accommodates weighted plates used to adjust the weight and balance of

the vehicle. The aluminum plate included in the kit is labeled as

having a mass of 13 grams. An optional thinner 9g aluminum plate

is also available, as are 24g and 36g steel plates, and an 8g carbon

fiber plate. If the electronics are installed onto this plate,

they can be easily changed as a unit. There is a second pocket

under the servo which is empty by default, but can accommodate a 5g

carbon plate, a 9g aluminum plate, or a 24g steel plate. This is

the

sort of thing I will never be changing. In fact, I won't be

changing any of the adjustments available on the chassis at all.

When you can't drive, nothing matters.

The 4mm thick front shock tower is made from carbon

fiber

plate and is attached to a plastic top plate. It is tilted back at

roughly the same angle as the chassis kickup. There are three

hole options for the upper shock mounting point. The center hole

is used by default. The front body

posts are attached to a bracket at the top of the shock tower as

shown. The bumper brace shown on the right is in the shape of a

loop to allow it to deform and absorb a lot of energy without breaking

in the even of a front impact (which happens a lot).

The front shock tower and plate assembly spans the

steering system and provides a closed box for structural rigidity of the

chassis and plenty of support for the shocks. You can also see

that the steering servo is well protected and supported by blue anodized aluminum brackets.

Now it is time to attach the front lower suspension

arms. Like all the plastics in this model, the front arms are

glass fiber reinforced. The arms are thick and riddled with

diagonal bracing. On the right you can see the aluminum brace

against the front bulkhead which helps support the hinge pins.

When the pins see big forces from jumps and impacts, they won't tear out

of the plastic bulkhead. A set screw keeps each hinge pin in

place.

The final step related to the parts from Bag 2 is the

installation of the front bumper. It attaches to both the bumper

brace and the chassis plate (through the front bulkhead), resulting a

very sturdy bumper even though it is quite thin.

The parts for the remainder of the front suspension

and steering are contained in Bag 3 and shown above. It doesn't

look like much, but there is a lot of adjustability built into those

parts.

The steering knuckle assembly is shown at left in both

an exploded view and a completed version. The knuckle itself is

plastic and uses two rubber shielded ball bearings to support the

hardened steel axle with 12mm hex. The "8.5mm" printed on the end

of the axle is the offset, not the hex size. Optional titanium

axles are available in case you want them to be much weaker for some

reason. There are two sets of knuckles

included in the kit which vary by having 3mm or 4mm trail. The

standard 4mm trail will give more straight line stability, while the 3mm

trail would offer sharper steering response. The ball stud is

offset from the knuckle using a carbon fiber plate. This plate is

listed in the manual as "+1", but it is not at all clear what this value

of 1 is added to because there is no baseline part to use for

comparison. After some research, it appears that this part puts

the steering ball stud 1mm further inboard compared to a baseline (not

included) part which will serve to provide additional Ackerman

correction to the steering. Apparently this is better for high

grip surfaces (like carpet) which is too bad for me because I will only

be driving this off road outdoors. The picture on the right shows

an exploded view of the caster block assembly as well as a completed

version. The plastic insert with a "5" printed on it adds an

additional 5° of caster to the 25° which comes from the chassis kickup

for a total of 30°.

It does this by containing an angled hole which will be used as the

pivot axis between the caster block and the lower suspension arm.

Optional 0° and 2.5° inserts are also included. Since they can be

flipped upside down, the amount of caster adjustment they provide can be

positive or negative. Combined with the 25° and 30° options of

the front bulkhead, this means the total caster angle adjustment range

is 20° (25°-5°) to 35° (30°+5°).

There is also a 1mm bump steer spacer under the steering ball stud and

two optional positions for the upper ball stud to adjust kingpin

inclination. The steering angle is limited by contact between the

knuckle and the caster block. A spacer can be installed to limit

the maximum angle.

What does it look like if you make every single

adjustment option the default? It looks like this. The front

steering parts have been installed, but the camber links will have to

wait until later because all the links in the whole kit get installed in

one step near the end. Although you can't really see it in the picture,

there is a 1mm spacer on the hinge pin just behind the caster block

which moves it all the way forward. Moving the spacer to the other

side would slightly reduce the wheelbase.

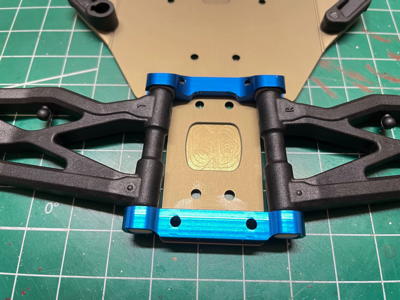

Bag 4 contains the parts for the rear

suspension. Most parts are plastic, but you can see the blue

anodized aluminum suspension mounts.

The left and right rear lower suspension arms are

identical. Those inserts you see in the left hand picture are used

to change the position of the lower shock attachment. There are

two types, one with a slightly off center hole, and one with a very off

center hole. Since they can also be flipped, that results in four

position options. The advantage of this system over just having

multiple holes in the arm is that the optional holes can be much closer

together without overlapping and losing strength. The stock

position is the second most outboard option. According to the

manual, the name for those white bits you see on the right is "pill

inserts". Zoom in and you'll see a mark on the back of each

indicating the relative position of the hole in the square. The

hole can be either in the center, 0.35mm toward an edge or a corner, or

0.7mm toward an edge or a corner. Selecting a pair of matching

inserts with holes further inboard or outboard will result in a change

in track width while selecting a pair of matching inserts with holes

further up or down will result in a change in roll center. Mixing

inserts from side to side results in 0.5° or 1° changes in rear toe

angle while mixing them front to back changes the anti-squat

angle. Standard toe angle is 3° but can be adjusted from 1° to

5°. Standard anti-squat angle is 2° but can be adjusted from 0° to

4°.

Here one of the rear suspension mounts has been

installed and you can see the default boring inserts with central

holes. The aft suspension mount is wider as you can see on the

right which results in a toe angle even when using the central insert

holes. That milled pocket you can see between the suspension arms

makes space for the teeth of the differential gear allowing it to be

mounted as low as possible.

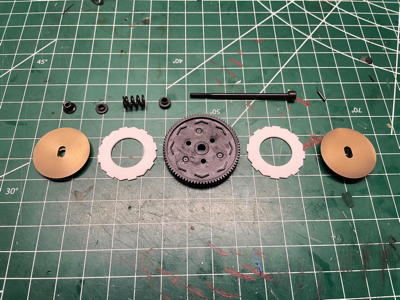

Bag 5 contains the parts for the ball

differential. On the right you can see that it is built with a

total of 14 balls with a diameter of 3/32". There is a tiny

container of clear ball diff grease in the kit. The differential

outer spur gear has 52 teeth.

The thrust bearing uses 6 balls of 5/64" diameter that you have to be

careful not to get mixed up with the diff balls since they vary by only

1/64 of an inch. There are no extra balls, so you'll have a real

bad day if you lose any of them. A tiny screw is used to clamp the

diff together across a compression spring allowing easy adjustment.

Things just keep getting more complicated. Bag 6 contains parts

for two different version of the transmission, and the names of those

options are not at all helpful. One is called "lay back" and the

other is called "lay down" which pretty much sound like synonyms.

Both have the same gear ratio and low mounted motor height, but the lay

down option has the motor 6mm further forward. The lay back option

is default and the more aft motor position gives you more traction on

loose surfaces. Moving the motor forward with the lay down version

would provide more steering traction instead. To achieve the more

forward motor position, the lay down transmission uses a larger idler

gear. The names of the parts for the different transmission

options are all mixed together in the manual making it very difficult to

figure out which parts to use. For the kind of driving surface I

am going to use (gravel), and standard "stand up" transmission

arrangement would actually be better, but that's not one of the

options. That's what I get for buying a racing chassis and using

it for bashing.

We will be building the lay back transmission starting with the

(apparently) aluminum top shaft and the Nylon idler gear shown on the

left. After the gearbox halves are joined, the aluminum rear ball

stud mount is installed spanning them. There are 2mm of spacers

underneath each ball stud which are installed in the center of three

hole options. There is also a slot for a rear sway bar, but this

is not included in the kit.

These inserts which support the bearings can be used

to slightly change the height of the differential within the gearbox

housing. It is not at all clear to me why this would make any

difference in how the car performs. The manual claims setting the

diff higher for high grip tracks is a good thing, but does not explain

why. It is probably to keep the drive shafts as close to

horizontal as possible. Moving the diff would also change the way

the gear teeth mate with the idler gear. The extreme high or low

positions would have less tooth engagement, but this must be a minor

impact since there is no adjustment for it. The default position

is the lowest so that's what I used.

Here the cover has been screwed onto the gearbox

housing as shown on the left. On the right I've attached the

aluminum motor mount plate, the gear guard, and the chassis brace which

will help stabilize the gearbox on the chassis plate.

The slipper clutch uses two friction pads, one on

either side of the spur gear. The friction pads are keyed to the

spur gear and spin with it, but the gear itself is not keyed to the

shaft it rides on. Rather, the aluminum slipper hubs have slots

which key to the shaft. So when torque is introduced into the spur

gear teeth from the motor, the only path into the shaft is through the

hubs via friction. Thus, the clamping force across the slipper

determines the maximum torque that can be transmitted. This is a

high power model, so the slipper needs to be pretty tight. It

protects the gears and axles from very abrupt changes in torque.

Now we can make the whole assembly more gangly by

adding the 4mm thick carbon fiber shock tower. It seems to me that

the plastic mounting interface to the gearbox housing is a bit small

for a tower this large, but so far it seems to work. There are

three hole options on either side for the upper shock support (the

center hole is default). On the right I've also added the rear

body posts which cantilever quite far behind the shock tower.

Let's add even more parts before connecting this to

the chassis. The final bits shown at the left are for the rear

bumper. Unlike the front bumper, the rear doesn't have a big

flexible loop to absorb impact. it is pretty sturdy being braced

in multiple directions.

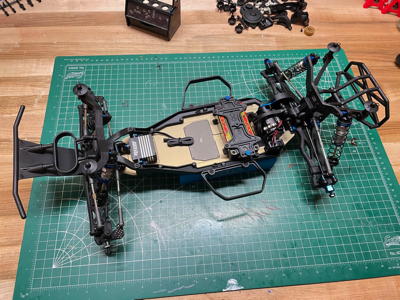

At long last the rear gearbox assembly can be attached to the chassis

resulting in the nearly complete version shown at left. The photo

on the right shows the unused parts left over which are for the "lay

down" transmission option.

Bag 7 contains the parts for the rear hubs and axles. There are

not very many parts here and not as many adjustment options as for the

front hubs, but still plenty of complexity.

The inserts shown in the photo on the left have holes either 1mm or 2mm

off center which can be flipped, thus offering four different

options. The hinge pin will pass through this hole and control the

position of the hub relative to the lower suspension arm. There

are a pair of 2mm spacers positioning the ball stud for the camber link

in the lateral direction, and another 2mm spacer in the vertical

direction. Any of these could be altered. The axles have a

CVA style universal on the inboard side and a dogbone end on the

outboard side.

When the rear hubs are attached to the lower arms,

they are installed with a spacer on either side. Moving both

spacers to a single side would either slightly increase or decrease the

wheelbase. The hinge pin is retained with a tiny 2mm screw.

The rear hexes are aluminum clamping type.

Bag 8 contains six titanium turnbuckles and twelve plastic rod

ends. These comprise the four suspension camber links and the two

steering links. Since turnbuckles use reverse threads at one end,

rotation of the rod in a single direction lengthens or shortens both

ends at one allowing easy adjustment (if you have a dedicated turnbuckle

wrench). Now the suspension operates properly as a 4-bar

linkage. Since the upper and lower arms are not exactly the same

length, the camber changes as a function of suspension travel.

Now we get to build the beautiful shocks. The parts are contained

in Bag 9 and shown above. There are a lot of parts that go into

building these.

The rods are titanium nitride coated and the pistons are Delrin with two

1.6mm holes in the front and 1.7nn holes in the rear. The

aluminum

cylinders have a 12mm bore for both front and rear, though rear have a

longer stroke. Each shock has two dynamic seals and two rod

guides. All four shocks use 30wt silicone oil out of the

box. The shocks do not have a volume compensation bladder; instead

they use a

bleed screw to set the fluid level when compressed. When extended

there is a void, making these emulsion type shocks. The springs

have a substantially different rate: 4.45 lbs/in in the front and 2.40

lbs/in in the rear. Many multiple variations of spring rate (3.75 - 4.45

lbs/in front, 2.2 - 2.7 lbs.in rear), rod end length (standard to

+2mm), fluid viscosity (10 - 70 wt), and spring cup height (0, 5, 9mm)

are available as well as completely different larger 13mm bore

shocks. A completed shock is compared with an exploded view at

left. At right they've all been installed, completing the

suspension.

Bag 10 finishes the model with the parts for the battery strap.

This model uses a shorty hard pack (as opposed to the rare square pack

used on the 5M) held down by a rigid strap with two thumbscrews.

On the left I've test fit the battery and installed the motor and pinion gear. I'm using a 6.5T motor, so I matched it with an 18T pinion. The side rail also has a spot to install a cooling fan for the motor so I did that as well. On the right I've also added the electronic speed controller and the receiver. I'm using a Spektrum receiver with AVC (Active Vehicle Control) to keep things stable and compensate for my driving skills. There is a second fan on the ESC. Finally, I've added a set of Proline KR2 tires.