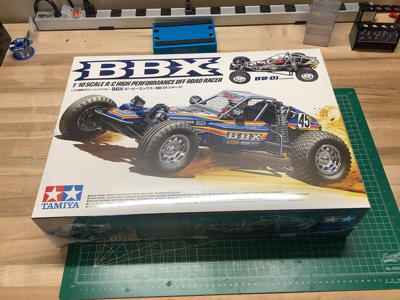

The BBX comes in quite a large box which is separated

on the inside as shown. There are no blister packs, but the body

is in a separate spot from the plastic parts, and the hardware has it's

own inner box. This model gets real, old fashioned, hand drawn box

art!

As usual, I laid out all the parts on my build table

as shown. There are five sequential hardware bags and a large

number of plastic parts sprues. Pretty much all of the plastic is

Nylon (polyamide), but most of the structural parts are glass

filled. On the right I show the contents of hardware bag A which

will built the gearbox and motor mount.

Here are the three shafts making up the gearbox. On the left is

the ball differential which uses Imperial sized balls (3/32") which is

unusual for Tamiya. The center shaft holds the idler gear.

The right hand shaft is the input which will connect to the spur.

The spur gear is 48p (not metric) as well. On the right I've

installed the gears into the housing and mounted it to the plastic

chassis tub. I've also installed a temporary brushless motor until

the right one arrives.

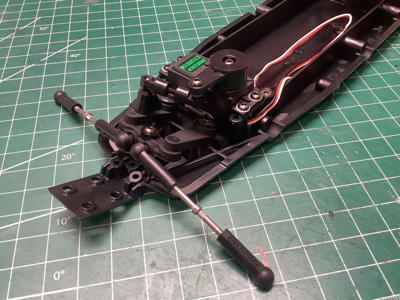

Hardware bag B contains parts for the rear suspension and

steering. On the right you can see the dual bellcrank steering

linkage installed along with the steering servo. Note that a low

profile servo is required and uses a high torque servo saver. The

steering links are turnbuckles.

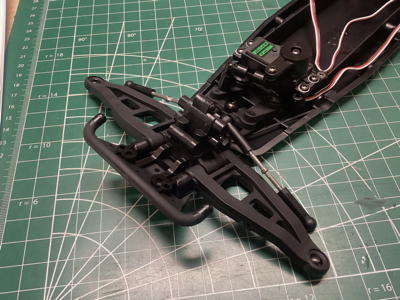

The four links shown on the left are the lateral supports for the rear

trailing arms. The link length is not intended to be

adjustable. On the right I've installed the link assembly onto the

chassis. The angled plate above the area is intended for the

speed controller.

Hardware bag C is for the front suspension and the beginnings of the

roll cage. The right hand image shows the front roll cage which

spans to the front bumper and has numerous cross members. The

driver figure serves as a cover for the receiver. The battery

slips under the driver by removing the lateral aluminum locking bar

shown. The whole driver platform has to be tilted up to access the

battery.

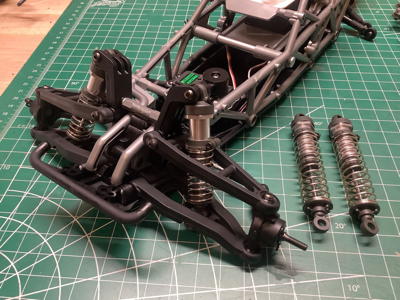

Here I've installed the front suspension. The upper and lower arms

are both wishbone type which provides excellent support. There

are ball joints in the end to support the steering knuckles. The

shock towers are separate plastic supports which are quite thick.

The front bumper is minimal and does not protect the suspension arms.

Hardware bag D is for the shocks and axles. The

shocks have aluminum bodies with plastic caps and rod ends. The

shock bodies are not threaded, so preload adjustment is done with a

clamping collar. The front axles use quite a lot of preload as can

be seen in the picture on the right. The front shocks install

between the wishbone of the suspension arms which makes for a much

stronger installation than a typical cantilever.

The rear shocks connect to the trailing arms which pivot off of a joint

in the roll cage. There is a nut trapped in the roll cage for

strength at this joint. The steel axles are CVD type at the outer

end and dog bones at the inner end. In the right hand photo I've

also installed the rear roll cage above the motor and gearbox, and the

side cages which protect the trailing arms in the event of a rollover.

The tires and wheels are new and (so far) unique to

this vehicle. The wheels have a chrome finish and the tires have

nice internal foams for support. The right hand photo shown the

completed rolling chassis. The buggy would actually look very good

just like this with no body at all.