TW-715 Project

Page 7: Installing the Electronics

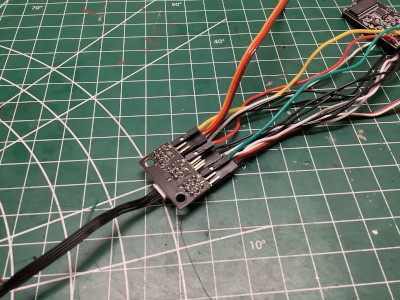

There is a reason I left the electronics until the very end on this

model. There is a tremendous amount going on here. The above

picture shows my first attempt at connecting everything together, and

even this is a simplified version for reasons I'll discuss

shortly. As a baseline, here is the channel breakdown:

- Channel 1: Steering. I originally planned to use a

ProTek Black Label 370TBL with 650 oz-in of torque at 7.4V powered by a

Hobbywing 10A UBEC. I needed a Y-harness to run the steering wheel

servo

off the same channel where I installed a Protek high voltage micro

servo. The steering wheel turns the wrong direction compared to

the axle, so I installed a servo reverser in series with the micro

servo.

This channel also needs to run to the lighting system so the turn

signals know when to flash. The instrument panel also indicates

the turn signals.

- Channel 2: Throttle. This carries the power from

the

Hobbywing 1080 ESC to the receiver. When using an external BEC,

the positive wire to the receiver would be disconnected.

This channel needs to be split

to the lighting system so brake lights can work. Instead of

traditional white reverse lights, the tail lights flash when backing

up. The headlights also get brighter when moving forward.

Finally, the throttle position is shown on the tachometer on the

instrument panel.

- Channel 3: Transmission. This controls shifting of the

2 speed transmission with a Protek high voltage micro servo. This

needs to be split to the instrument panel which indicates selected

gear. This is mapped to a 3-position switch with neutral in the

center. I discovered later than multiple shift inputs switch the

lighting system between modes: all off, indicators only, all on.

- Channel 4: Transfer Case. This controls a Protek

high voltage micro servo to shift between RWD and 4WD. This is

mapped to a 2-position

switch.

- Channel 5: Locking Differential. This

controls an EcoPower 120T with 400 oz-in of torque at 7.4V to pull the

differential locking cables. Both front and rear axles lock

together. This is mapped to a 2-position

switch.

- Channel 6: Winch. This is used to drive the

winch. The winch is powered from the receiver rather than directly

from the battery like some other winches. This is mapped to a

3-position momentary switch.

If you were reading closely you may have noticed that I was intending to

run the entire system at 7.4V from a UBEC. When I hooked

everything up the steering wheel didn't work, and I eventually

discovered that my servo reverser only functioned at up to 6V. My

next plan was to run almost the entire system off the 7.4V UBEC but run

the steering wheel servo only from the 6V BEC in the ESC. This

would have been quite painful to wire. While experimenting, I

discovered that an external UBEC wasn't really necessary. The

Hobbywing 1080 ESC has a maximum of 6A of output which was plenty

without any brown out problems, so I just eliminated the UBEC from the

circuit entirely. Later I got a higher voltage servo reverser

allowing me to switch the internal BEC back to 7.4V. The

instrument panel includes a battery charge indicator, so that meant I

had to split power directly off the battery with a JST connector to

power the panel. Luckily it is capable of 2s or 3s voltage so I

have battery options. I also eventually realized that my temporary

EcoPower 120T steering servo had plenty of torque so there was no

reason to spend an additional $100 on the Black Label.

The lighting system and instrument panel were a big surprise because

they were not documented at all on the web site or promotional

material. The PCB shown on the left is a splitter for Channels 1-3

with additional outputs to an external lighting board and an

instrument panel. That instrument panel is shown on the

right. The speedometer, tachometer, and the area between are all

part of a single rectangular panel. Let's start with the center

area. That "N" in the center is indicating that the transmission

is in neutral and it will change to 1 for Low and 2 for High. The

upper portion of that area is currently blank but it has green arrows

for when the left or right turn signals are flashing. The

tachometer is on the right and it indicates throttle position. The

ring around the outside of the tach indicates battery charge. The

red and yellow arcs shown indicate semi-low battery. Additional

green arcs would be present for a more full battery. The

speedometer on the left doesn't really indicate speed, but it parallels

the tach when the transmission is in gear. It is smart enough not

to show anything on the speedo when the transmission is in

neutral. The speedo does not indicate any more speed in high gear

than in low gear even though it has all the necessary information to do

so. The additional panel in the center of the dash is a

clock and the three buttons beneath it are for setting the time.

There is a button cell battery in the clock PCB so it remembers the time

even without a battery in the model.

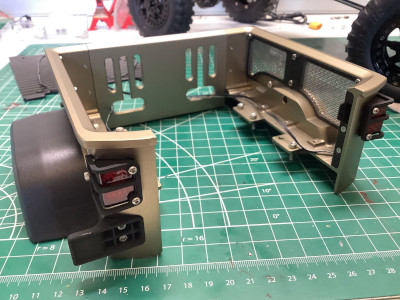

This model doesn't use individual 3mm or 5mm LEDs for lighting, instead

everything uses chip mounted LEDs. On the left you can see the

backs of the boards for the headlights. The turn signals each

consist of 5 LEDs that move sequentially to indicate turn

direction. It's pretty cool.

There are 5 chip LEDs for each tail light as shown. The two on top

are red and are used for tail lights, brake lights, and reverse

flashers. The three on the bottom are amber and are used for turn

signals. The amber seems to show up OK through the red painted

lens. The wires can

be completely hidden behind the plastic tail panel and then under the

bed deck.

I procrastinated doing the diff lock cables until the very end, but it

turned out not to be all that difficult. Again, there was

absolutely nothing about how to do this in the basic instruction

videos. There was a separate video just for rigging the cables,

but it was only in Chinese. This photo shows how the cable shrouds

terminate and how the cables clamp to the actuation mechanism.

There are spring cartridges in series with each cable that help to

reduce the load on the servo when the locks are engaged.

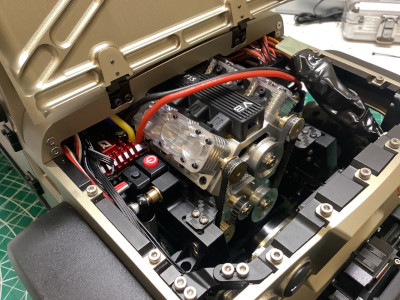

These pictures show the best I was able to do to consolidate and hide

all the wiring. The piles of servo connections are inside that

bundle of electrical tape. That wire running over the top of the engine

is the battery cable. I ran out of bandwidth in my brain to do any

more work on routing.

©2022 Eric Albrecht