TW-715 Project

Page 6: Building the Body

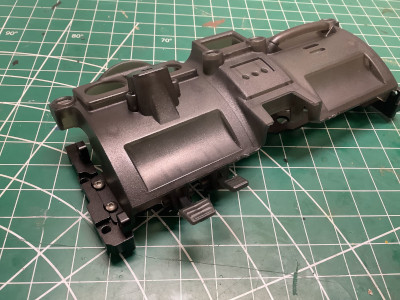

The dashboard actually forms an integral part of the front of the body,

so assembly starts with that. The dashboard is backed by an

aluminum support bracket which is then fastened to a pair of supports

forming the top of the front wheel arches as shown on the right.

The geometry of these front brackets is quite complex. The angled

supports and cross braces shown form the structural backbone of the

front of the truck. However, since all the body panels are also

metal, they significantly stiffen the entire assembly once installed.

The machined front of the truck is shown from the back side along with

the photo etched grille. The light lenses would normally be

installed now, but I am coming back to do the painting and electronics

later so I only installed the mounting screws.

This picture shows the machined front face attached to the backing structure. It is starting to look like a truck!

The fender flares on this truck are massive and required me to make a

difficult decision. According to the pictures of the real truck,

the fender flares are painted the same color as the rest of the

vehicle. I knew there was no way I was going to be able to paint

the molded flares and get them to actually match. My next option

was just to paint them black. I finally decided that since many

Jeep's actually have plastic fender flares and the texture of those used

on the model was a very good match, I'd just leave them alone in their

unpainted condition. I don't feel like they look unfinished at all

compared to the rest of the model. I did decide to tap all the

holes into the plastic to prevent and chance of splitting. I also

used double sided tape

to attach the photo etched side vents as shown.

The next step is to install the A-pillars and windshield support.

This is a heavy machined component that is actually suitable as a roll

bar. Next is the air intake area behind the hood. Oddly,

even though the model is clearly provisioned for wipers (probably

motorized wipers), they do not come with the kit and are not available

as options either.

Now I can install the hardware which will attach the hood. These

trapezoidal hinges (left) look just like those on the real truck.

On the right you can see the front corner hood latches.

That completes the front end assembly (left). This assembly is

amazingly heavy even without the hood installed. When it was

placed on the truck (right), I was able to see the compression in the

front springs. You can again note how far back the engine

is. There is a lot of space up front, and the rear two cylinders

are actually tucked under the body. I don't know how accurate this

placement is compared to the real vehicle, but it doesn't even have a

V-8 so none of the engine bay is particularly representative. It

looks good though.

The instructions do not call for installation of the hood until the end,

but I went ahead and installed it anyway just to see how it

looked. It only takes four cap screws.

When it comes to making strong parts, the designers of this model were

not messing around. Take a look at that frame consisting A, B, and

C pillars made of machined aluminum. Those green panels fastened

over the top are aluminum as well. Considering the fact that both

the real truck and the model have removable doors, this structure needs

to be solid to protect the occupants.

The picture on the left shows the installation of the sliders which

sit just underneath the rocker panel. On the right I've installed

the door hinges which is where I ran into one of my only quality

problems with the body. One of the 8 hinges was not drilled for a

hinge pin. Drilling a 1.5mm hole in a tiny hinge with normal sized

tools is very difficult, to say the least. I did manage it

though.

I'm quite confident that the rear panel on the real truck interior is not

covered with slots like this one is. Those slots were useful

though. I was able to run a lot of the rear electrical wires under

the bed, through those slots, under the seats, and into the radio

equipment in the front.

Did I mention everything on this truck is complicated? Here you

can see the parts for a door on the left next to a completed door.

That mechanism inside is for the spring loaded latch. You

actually rotate the external door handle to turn the aluminum gear which

slide the acrylic rack gear connected to the latch. The internal

door card has a separate handle and a pocket. These photos show

the rear doors.

The front doors are mechanically identical to the rear but they are a

bit larger and are more rectangular. Just like the real vehicle,

you can lift the doors off the hinges any time they are open. The

front doors also have the large rectangular Jeep side mirrors.

Let's get started on the bed. Like the front arches,

these were left unpainted. The side panels and front wall are all

machined aluminum like almost everything else on the body. Those

slots of the front line up with slots on the back of the cabin.

Now I've attached the tail lights, the protective brackets, and the

license plate holder. It is hard to see what I've added on the

right, but is a small plastic cover to conceal the back side of the tail

lights where the wires will be.

The three sided bed can now be attached to the chassis. This is

effectively a step side bed with the wheel arches on the outside

and therefore has a flat bottom. Unlike most step sides though,

it is

still full width. The bed is the width of the cabin and the wheel

arches stick out even farther.

The tailgate latching mechanism is pretty complicated. The release

button sits on top of the gate and pushes down vertically. This

button compresses the spring shown on the left and also moves those two

large inner bearings down. As they move down, the angled slot

forces the side latches inward. Those side latches slide on two

more bearings each to stay level. This whole mechanism then gets

hidden by a machined carbon plate and hinged off an aluminum bracket as

shown on the right.

Now I've installed the tail gate onto the chassis. At this point I

can install the bed deck which is an aluminum plate. The real

truck has a wooden bed deck.

There are big cutouts on the sides of the bed, so to close those off

we'll use some photo etched screens. More carbon plates are used

to support and attach the screens. This is one of the few places

on the model in which we don't have tapped holes so we need to use tiny

nuts instead.

The real truck has a soft top, but the model uses a thick aluminum plate

with an open sun roof. This makes a convenient hand hold for

lifting the model. Even the rear window frame is a massive chunk

of aluminum. Note that there are no windows in the doors, rear, or

roof. Only the windshield will have a transparency, but I'll

install that last to keep it pristine.

The chassis and body are done, so now we add the final structural

detail, the bumpers. Like everything else on this truck, these

have to be assembled from many pieces. The bumper itself is a

monolithic machined aluminum part that bolts directly to the frame, but

it is covered in the rubber like plastic covers shown on the left.

These are black and quite flexible. They attach to the bumper

with tiny M1.4 cap screws. I ran into another major problem

here. Many of the holes in the bumper were either not tapped to

full depth or tapped poorly so that the screws fit very tight. I

didn't have an M1.4 tap so I foolishly just applied extra torque trying

to get them in and sheared off one of the heads as you can see on the

right. Many of the others could not be fully tightened leaving

waviness in the flexible parts. This was a problem on both the

front and rear bumpers.

I ordered an M1.4 tap and waited a few days for it to arrive.

After re-tapping all the holes with a pin vise, everything went together

perfectly. The broken screw could not be removed though.

The next issue was with the D-ring shackles. The shackle itself

was drilled and tapped for M2.5, but the screw and hole in the bumper

were 3mm. I had to oversize the bores in the shackles and re-tap

to M3 resulting in the installation shown. Then I could finally

install the bumper onto the chassis. This is a seriously solid

bumper.

The rear bumper assembled in exactly the same way as the front, and it

had all the same problems. After correcting all the holes and

threads using what I'd learned on the front, it went together fine.

There were a couple of things I didn't like about the shackle

details. The first was that the shackle hinge bolt was way too

long (see photo from previous step) and looked terrible. I cut off

several mm with my Dremel and now they look much better. The four

bolts surrounding the shackle would be part of a plate bolted to the

bumper on the real truck, but on the model they are just for show.

I did not like that they were cap screws so I replaced them with tiny

hex bolts which I think look much better. Zoom in and you'll see

that I am (predictably) right.

The instruction videos make no mention of a battery box, and this two

piece machined box was actually in a separate container inside the kit

packaging. I wonder if it was added as a last minute

addition? It wasn't hard to figure out how to bolt it into the bed

right behind the cabin. It does a nice job of hiding the battery,

but it is kind of annoying that you need a hex driver to access the

battery. I've more than once taken this truck out to a trail only

to realize I didn't have a tool to install the battery and therefore

couldn't use it.

That's it! The initial assembly is completed. At this point

I've done only assembly; there are no electronics hooked up and nothing

has been painted. Now it is time to go back and do some detail

work.

The transparent parts come on an acrylic tree. It makes sense for

the lenses to be transparent, but the light buckets should be reflective

so I painted them with my liquid chrome paint pen as shown on the

right.

My next step was to paint the turn signal lenses in transparent

orange. I'm not entirely sure what those lights inboard of the

headlights are supposed to be, but on the real truck they are blacked

out with only the rectangular center illuminated in amber so I tried to

paint them the same way.

Let's paint some tail lights next. I painted the transparent

housings black and the lenses transparent red. Ideally the lower

portion of the lens would have a clear rectangular inset for the reverse

lights, but this model doesn't have reverse lights so I left them all

red. There should also be a rectangular inset on the outer side of

the housing for the turn signals but that level of fine detail is too

much for me. I think they look pretty good. The other parts

in the image were painted in black.

I'm pretty sure these insets behind the rear doors are supposed to be

steps. They look dark gray on the real truck so I painted them the

same way. It is the only place on the vehicle I used that

color. I wish they had been molded with a textured step instead of

just a smooth bottom. Finally, I painted the hood grilles in

black and glued them in place. This was the only place on the

model I used glue.

©2022 Eric Albrecht