Features

|

|

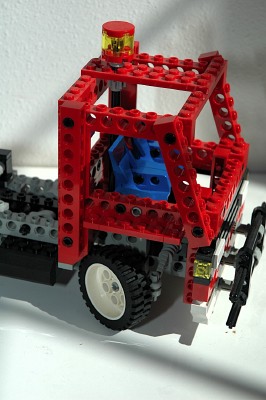

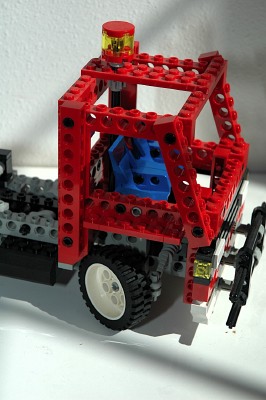

Tractor

The tractor is a single rear axle unit with dual wheels and

tires. It's a bit boxy but does a great job of integrating with

the set of while using minimal parts.

|

|

|

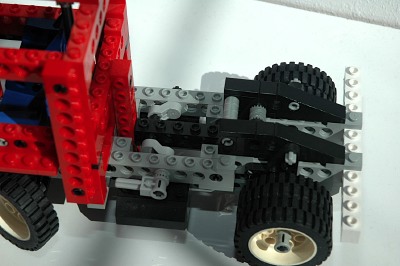

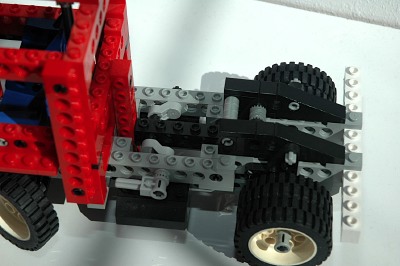

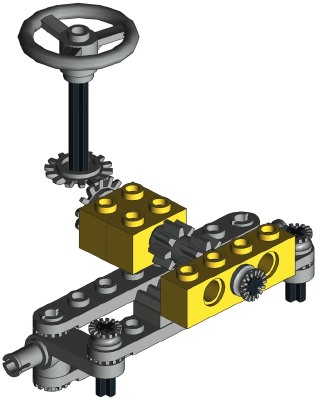

Steering

The front wheels can be steered using an overhead "hand of god" control. The overhead control drives

an axle connected to

a pair of 14 tooth bevel gears.

The second axle drives a flexible rack via an 8

tooth pinion

gear. The steering mechanism itself uses the steering arms

and toothed links as shown in the computer image.

Note that, in this case, the steering arms actually point forward

instead of back. This works OK with these control arms because

there is no caster (the wheel axle is centered under the rotation

point). If there were caster, this would be an unstable

arrangement since the reverse caster will cause the wheels to diverge

from center when moving forward rather than return.

|

Ldraw file courtesy of Benjamin Wendl.

Click for an animation of the

steering in motion.

|

|

Fifth Wheel

Coupling

The 5th wheel coupler works very much like a real tractor. The

coupling hitch on the trailer slides in between the side rails as the

tractor backs up to it. After the pin contacts the forward stop,

the unit is locked.

This coupler is locked via a crank on the left side. The pole

reverser handle turns an axle attached to a pair of crankshaft

elements. These pull a link which is attached to a pair of

triangles. When these triangles are pulled forward, they engage

the trailer pin. Since the crankshaft elements go over center,

this locks the pin in position so that towing force cannot pull it

open. This effect can be seen in the animation.

|

Ldraw file courtesy of Benjamin Wendl.

Click for an animation of the

coupling engaging. |

|

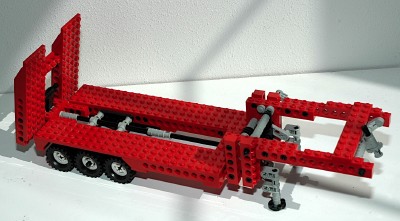

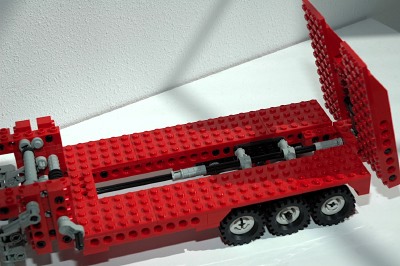

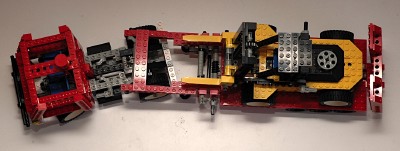

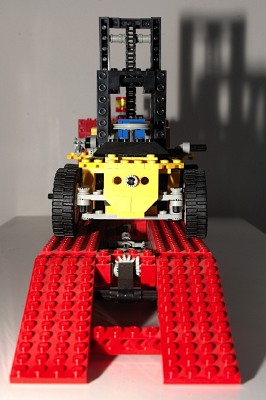

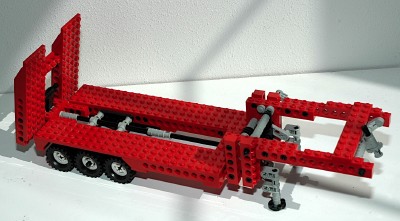

Trailer

This low frame multi-axle trailer is obviously designed for hauling

heavy equipment. It has an open frame and a sturdy loading ramp.

|

|

|

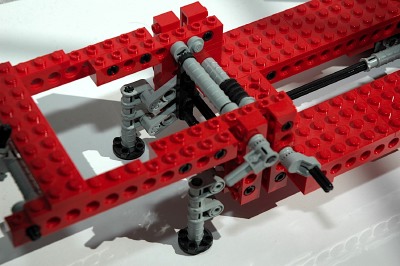

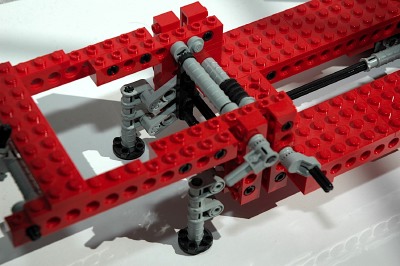

Landing Gear

The "landing gear" is the pair of feet which deploy to support the

front of the trailer when not attached to a tractor. They raise

and lower on a 4-bar linkage, keeping them perpendicular to the

ground. A pole reverser handle turns an axle attached to a pair

of crankshaft elements. These drive a link which moves the 4-bar

linkage. Since the crankshaft elements go over center, this locks

the feet in the down position so they do not collapse under

weight. In the photograph you can see that these parts are

stopped against a pair of 1x1 round plates which prevent further

rotation. |

Ldraw file courtesy of Benjamin Wendl.

Click for an animation of the

landing gear deploying. |

|

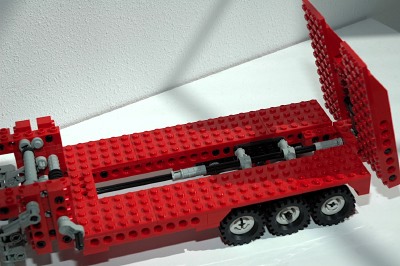

Loading Ramp

The large rear loading ramp is driven by a crank on the front

side. This crank turns a worm gear which mates with a 24 tooth

crown. An axle runs the whole length of the trailer and then

drives a perpendicular axle through a set of 14 tooth bevel

gears. This final axle drives a pair of liftarms which raise and

lower the ramp.

Because the mechanism uses a worm gear, it cannot be backdriven

(because the axial friction is higher than the

backdriving torque due to the screw pitch angle). This

helps keep the ramp up when in transit.

|

Ldraw file courtesy of Benjamin Wendl.

Click for an animation of the

loading ramp

in motion. |

|

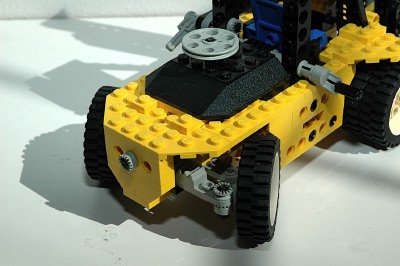

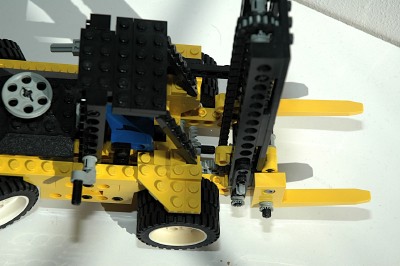

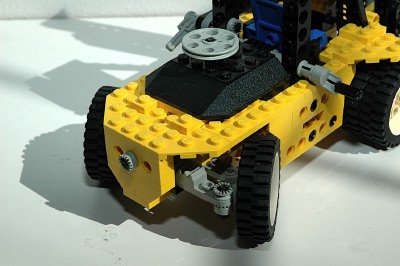

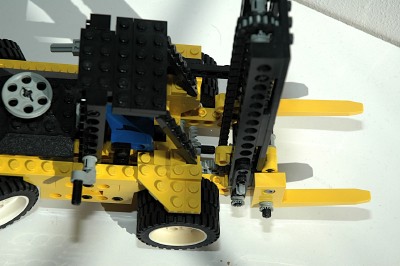

Forklift

If we are to assume that the forklift is to scale with the rest of the

set, then this is a huge forklift indeed. It would be perhaps 30

feet

long. There are forklifts this big which would typically be used

for

heavy loading of things like shipping containers. The double

front tires suggest that this is designed for very heavy lifting.

The train roof used as an engine cover is a nice touch.

|

|

|

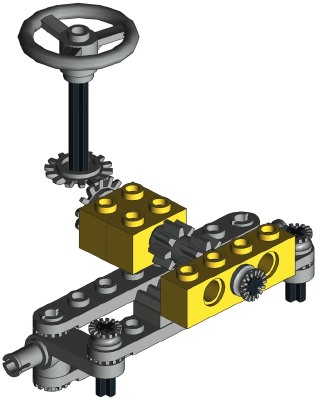

Steering

The rear wheels can be steered using an overhead "hand of god" control

behind the cabin. The

wheel control drives

an axle connected to

a pair of 14 tooth bevel gears.

The second axle drives a rack via an 8

tooth pinion

gear. The steering mechanism itself uses the steering arms

and toothed links as shown in the computer image. |

Ldraw file courtesy of Benjamin Wendl.

Click for an animation of the steering

in

motion.

|

|

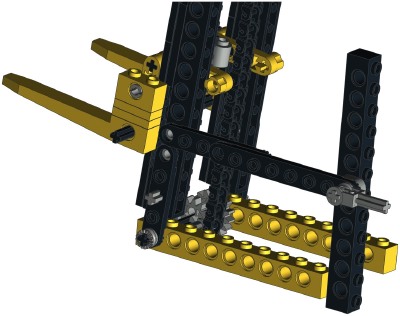

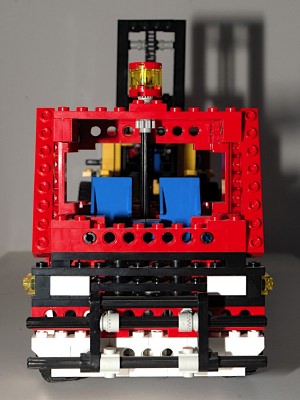

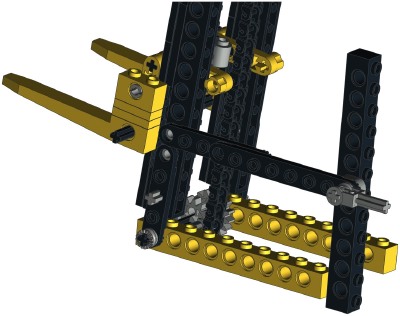

Lift

The forks are lifted via a fairly complex gear train. A crank on

the right side turns a worm gear. The presence of the worm gear

ensures that no weight on the forks will backdrive the system.

Next is a 24 tooth crown followed by a pair of 14 tooth bevel

gears. Then there's another gear pair with a 24 tooth crown and a

16 tooth spur. This drives yet another 16 tooth spur. It is

important to note that this second spur gear is on the same axle about

which the whole fork assembly tilts. This allows torque to be

passed through this joint no matter what position the tilt is in.

A final pair of 16 tooth spur gears are located at the top and bottom

of the fork boom. They are connected by a long chain loop.

A single chain link is the wide (tread) variety. This connects to

the fork assembly and forces it to follow the chain movement.

The fork assembly is one of the least binding of the Technic

forklifts. A series of tiles along the front of the boom keep the

forks from tipping into the boom, and the flanges on a pair of liftarms

keep the forks from tipping away. The semi-round nature of the

liftarms keep everything moving smoothly as it slides along the boom.

|

|

|

Tilt

The forks can be tilted via a pole reverser handle on the left

side. This handle drives a crankshaft element connected to a

link. The link tips the whole boom assembly about the lower pivot

axle.

Since the crankshaft element goes over center, this locks the boom in

the transport position so the lift weight will not cause the boom to

tip forward.

|

Ldraw file courtesy of Benjamin Wendl.

Click

for an animation of the forks tilting. |

|

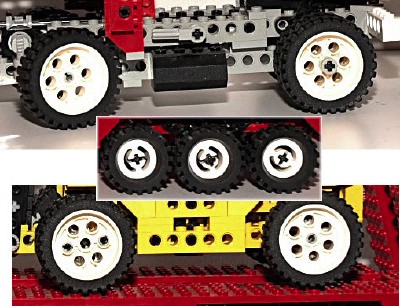

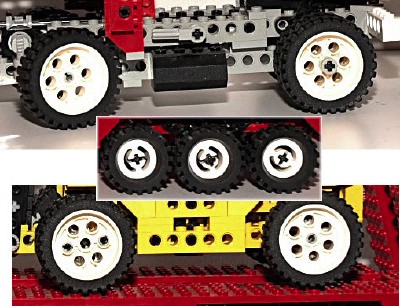

Wheels and Tires

This set is a gold mine of wheels and tires.

The tractor and the forklift each have 6 of the Model Team wheels and

tires, for a total of 12.

The trailer has 6 of the old style small wheels with the medium size

tires.

|

|