Features

|

|

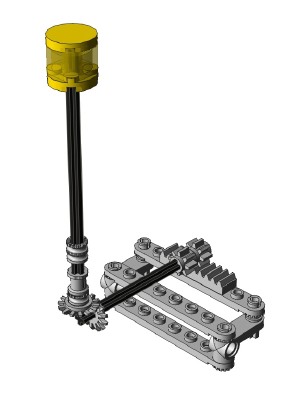

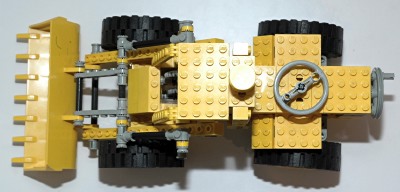

Steering

The rear wheels can be steered using an overhead "Hand of God" control.

The overhead control drives an axle connected to a pair of 14 tooth

bevel gears. The second axle drives a rack via a pair of 8 tooth

pinion

gears. The steering mechanism itself uses steering arms and

toothed links as shown in the computer image.

|

Ldraw file courtesy of Benjamin Wendl.

Click for an animation of

the

steering in motion

|

|

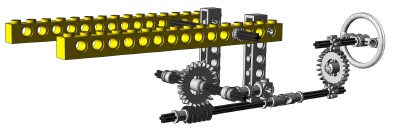

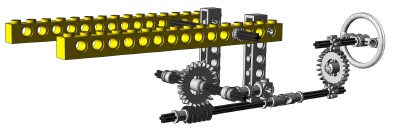

Bucket Lift

The front bucket can be lifted via a crank in the rear of the

vehicle. The crank drives an 8 tooth pinion which passes through

a 24 tooth crown gear and then another 8 tooth pinion, cancelling out

the gear ratio change. The torque the passes through a U-joint

and turns a worm gear. The worm gear mates with a 24 tooth crown gear,

resulting in 24:1 gear reduction. The crown gear axle attaches to

toothed connectors which rotate a pair of crank arms. The crank

arms

push and pull 6L beams used as links which drive the bucket boom up and

down.

The use of a worm gear results in a system which cannot be backdriven

(because the axial friction is higher than the

backdriving torque due to the screw pitch angle) which allows the

bucket to be supported so that it does not fall under its own weight.

Because the boom pivot and the dumping mechanism share an axle, their

movement is dependent. As you can see in the animation, even

though the dumping mechanism link remains fixed in space, it rotates

with respect to the boom as the boom lifts resulting in the bucket

dumping.

|

Ldraw file courtesy of

Benjamin Wendl.

Click for an animation of the

bucket

lifting.

|

|

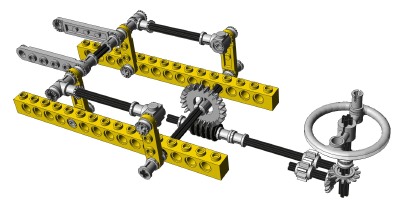

Dump

The front bucket can be dumped via a crank on the top rear of the

vehicle. The crank drives a pair of 14 tooth bevel gears and then

a pair of 8 tooth spur gears, one of which is connected to a worm

gear. The worm gear mates with a 24 tooth crown gear,

resulting in 24:1 gear reduction. The crown gear axle attaches to

toothed bushings which rotate a pair toothed links used as crank

arms. The crank arms drive a set of push/pull rods which control

rotation of the bucket.

The use of a worm gear results in a system which cannot be backdriven

(because the axial friction is higher than the

backdriving torque due to the screw pitch angle) which allows the

bucket to be supported so that it does not fall under its own weight.

The orientation of the toothed bushings and connectors in this system

is very important. If the bushing faces a link, they lock together

and move with the axle. If the bushing faces away from the link,

the link can rotate freely on the axle. The top

view shows this clearly.

|

|

|

Wheels and Tires

This set uses four of the smaller size foam 20x30 tires and wheels.

|

|