Tamiya TRF 417X Project

Page 2: Assembling the Chassis

While writing about this build, I am going to concentrate on the

differences between this and the last chassis in the TRF line I built

(the TRF 416)

The TRF 417 (and the prior TRF models) had a ball differential but the TRF 417X came with these GV

parts which are the internal gears for a rear sealed gear

differential. The carbon filled Nylon parts were first introduced

with the TA-06 earlier in 2011, about the same time as a special edition

of the TRF 417 was released with the same option. The plastic

cross piece which supports the spider gears was not used for the TRF

models; metal shafts were used instead.

Here we can see the Delrin housing for the gear differential along

with the gears, bearings, shafts, seals, and oil. The kit comes

with clear (900 weight) shock oil for filling the differential which is

actually pretty thin and offers only minimal resistance to motion.

The 37T pulley is built into one side of the housing. On the

right I've inserted one of the aluminum drive cups and placed an o-ring

over it. This will serve to keep the oil inside the differential

where it belongs. There are no bearings supporting the drive cups;

they ride directly on the diff housing.

A 0.1mm shim is then placed over the seal followed by a 1.6x8mm

pin. Inserting the pin is an exercise in frustration because of

the very limited access. You'll need a sharp pointed tweezers to

manage it. The side gears fit over the pin which lock them to the

drive cups. On the right you can see that I've also installed the

gasket which should seal the two housings together.

The four spider gears are supported by titanium coated cross shafts

which are notched to overlap at the center as shown on the left.

Optional steel gears are available if you want to make more noise.

After this step the volume is filled (mostly) with oil. On the

right the two housings have been connected with four tiny 2x8mm countersunk

screws and then the large 15x10mm bearings and tensioning cams have been installed.

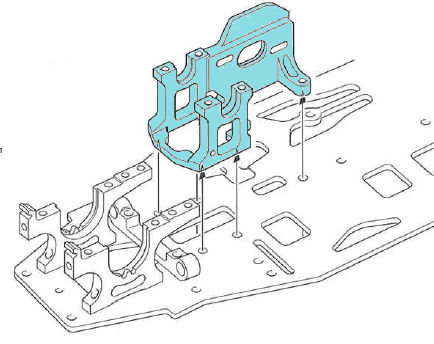

My personal suspicion is that

the primary reason for the TRF 417X was to get rid of the one-piece

center bulkhead which had to be machined out of a giant block of

aluminum and replace it with a three-piece version that could be much

more simply machined out of thin plates. Tamiya says "the previous

one-piece motor mount has been replaced with a three-piece type to

allow further adjustment of chassis flexibility by linking them

together", but that sounds like marketing spin to me. I compare

the center bulkheads in the images above, and you can see how difficult

it would be to machine the one-piece mount with only the minimal base

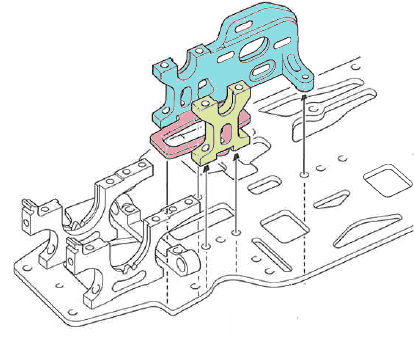

connecting the vertical sides. The new bulkhead could potentially

be installed omitting the center (red) part which would reduce stiffness

in the chassis, though the manual makes no specific mention of this

option. These images also convey the relief

cuts that were added to the lower chassis deck to add flexibility.

Here we can see the parts for the new three-piece center bulkhead as

well as the rear bulkheads and suspension mount. Whereas previous

models had used unique front and rear bulkheads, for the TRF 417 models front and rear use the same parts.

These upper bulkheads are very similar, but not identical, to those from

the TRF 416. After the rear differential is installed with the

short rear belt, the upper bulkheads capture the bearings as well as

providing three mounting hole options for the upper suspension links.

These pictures show the belt tensioning cams. The picture on the

right shows the little triangular indexing mark which is aligned with

the tang on the bulkhead for the default position. The cam can be

rotated to move the bearings forward or backward to add or relieve

tension on the belt. The whole cam can also be flipped 180 degrees

(aligning with a circular mark instead of the triangular mark) to

decrease the ride height.

The 105T spur gear from the TRF 416 has been replaced with two options:

111T and 113T (left). Those six large holes around the outer edge

are used to access the motor mounting screw. The 15T center

pulleys have also been replaced with larger 19T versions (right).

These seem to be made from three parts: an aluminum housing and cap, and

a bronze toothed pulley. It is not immediately clear how these

are connected, but I suspect they are just pressed together. They

cannot be disassembled.

The pulleys are connected directly to the spur gear so there is no

center one-way bearing in this design. The center shaft assembly then

drops into the center bulkhead. One subtle difference from the TRF

416 is that now the short rear belt is on the left side of the spur

gear instead of on the right. This leaves slightly less room for

the battery but more room for electronics. This may have been done

because the TRF 417 was the first Tamiya chassis designed for brushless

motors which use larger controllers, and lithium batteries which are

much lighter and can be installed further outboard.

Now we can install the front bulkheads, front suspension mount, and

steering posts. That black steel part with "TRF" written on it

doubles as both a 15g ballast weight and a side positioning stop for the

battery.

All of the TRF chassis had used a front one-way through the TRF 416

until the World Edition. The TRF 417 models all use a front direct

coupling which is just a solid shaft that passes through (and locks to)

the front

pulley and attaches directly to the drive cups. These are plastic

drive cups with an aluminum retaining ring over them, presumably to keep

them from ballooning at high rpm. I'm not sure this strategy

saves anything over just making them from aluminum to start with. I

suppose the plastic provides some amount of cushioning when applying

sudden power to the front axles.

Here the front pulley has been installed and captured by the upper

bulkheads. The front upper bulkheads are the same parts used on

the rear. Both belts are now installed and tensioned.

These steering cranks and bridge are very similar to those from the TRF

416. One difference is that there is now no bracket

connecting them together and to the upper chassis deck; instead they just float above the lower chassis deck. This

supposedly adds more flexibility to the chassis.

The upper deck connects the front and rear bulkheads and also captures

the bearings for the center shaft. This means the whole upper deck

has to be removed to access the center shaft for maintenance.

There is also a smaller upper brace that connects the rear bulkheads to

the center bulkheads. There is a center belt support

built into the upper deck as shown on the right.

Tamiya sure does like changing suspension arms. These new arms

(front and read) were introduced with the TB Evolution 5 and have more symmetric bracing

compared to the older arms. They are made from carbon filled

plastic and are quite rigid. Flipping them allows access to different ball joint positions.

The uprights have not changed, but the CVD axles have. Whereas the

TRF 416 axles retained the cross pin with a set screw, the TRF 417

axles use a circular retaining ring with a tang that clips into a hole

in the axle. These retaining rings are installed symmetrically on

the left and the right so that their direction of spin tends to keep

them installed rather than loosen them. The clamping wheel hexes

have stayed the same.

As previously discussed, the front arms have also been changed.

Here the integral plastic ball joints are being used to connect to the

vertical rods for the sway bars. The plastic balls are 4mm (versus

5mm for the aluminum versions), so smaller ball cups (black) need to be

used, and the larger cups (gray) at the other end need to be trimmed to

fit.

Here's a closer look at some interesting parts of the front

suspension. Can you spot the

difference between those bushings (left)? Probably not because one

of

them is 4.5x3.5mm and the other is 4.6x4.7mm (both with a 3mm

bore). The difference in

height may have some explanation, but why the 0.1mm difference in

outer diameter? Is it to prevent installing the larger one in the

wrong

hole? Nope, the hole tolerances are such that it fits

anyway. The primary effect is that it is really easy to get them

wrong when building the front suspension which uses one for the upper

kingpin and the other for the lower. These parts are carried over

from the TRF 416. Can you spot the

difference between those pins? Probably not because one is 2x9.8mm

and the other is 2x10mm. The shorter one is used in the CVD

axles and the longer one to drive the wheel hex. The length of the

shorter one is presumably dictated by fitting inside the

retaining ring. Why not make all four 9.8mm? Probably

because no one makes 9.8mm pins so Tamiya has to cut them down from

standard 10mm pins. That's my guess anyway. Can you spot the

difference between those two shims? Probably not because one is

0.5mm thick and the other is 0.7mm thick. Unless you have a

digital caliper (which I don't), it is pretty hard to figure out which

is which. The thicker one is a spacer for the steering knuckle, so

inadvertently installing the thinner one instead will introduce some

vertical play. The thinner one is a spacer for the upper ball

joint. The bearings are shown just to highlight the light gray

annular rings which identify these as fluorine sealed bearings, the best

that Tamiya makes.

The hub carriers (F-parts with integrated 4° caster angle) are carried

over from the TRF 416 which in turn came from the TA-05 IFS. The

steering knuckles (C-parts) are also from the TRF 416. Only the CVD

axles have changed by introducing the retaining ring.

While the sway bar system appears to be identical to that used on the

TRF 416 with a soft rear stabilizer and medium front stabilizer rod, the

part numbers are different. Other stiffnesses are possible but

not included in the kit.

These photos show the completed front sway bar installation (left), and

rear sway bar installation (right). Like all of the other TRF sway

bar installations up to this point, I find that they are not very

effective due to insufficient support at the pivot axis.

Time to build the shocks which is always one of my favorite parts.

These TRF Special Dampers are the same size and use most of the same

parts as the TRF 416 dampers, but with very subtle differences.

The position of the rod seal and rod support ring have been swapped

(same parts, different assembly position). The TRF 417 also uses

the HL (High Lubrication) version of the cylinders which have a special

coating on them for reduced friction. This is visible as a slight

bronze color on the cylinder versus black on the TRF 416. Finally,

my copy of the kit included "bonus parts" which appear limited to the

extra set of springs shown at upper left. Based on the wire

diameter and pitch, these appear to be stiffer than the stock springs

and are labelled as being for use on carpeted (high traction)

tracks. The carbon shock towers are shown at right. These

have more hole positions that those from the TRF 416, but I'm not a fan

of overlapping holes since they are very structurally weak.

These photos show the completed front (left) and rear (right) suspension

assemblies with the shocks installed. This chassis is complete

apart from the electronics.

The TRF 417 is the first TRF chassis to have been specifically designed

for brushless motors and hard case racing batteries. I happened to

have an old unused Speed Passion brushless motor which seemed about the

right vintage for this chassis so I installed it. A regular silver can

brushed motor actually won't fit, although other Tamiya brushed motors

(like Super Stock) will. I've also installed a cheap steering

servo just to hold the wheels straight.

This side view shows the two ways to bolt the motor to the motor

plate. I've used the upper and lower holes which are located

diagonally but are partially blocked the the belt and therefore hard to

access. The other option is to use the center horizontal

holes. If these are used the left hand hole is only accessible by

passing your hex tool through one of the large holes in the spur gear.

The lovely steel battery supports double as12g ballast weights.

They don't provide any vertical support so glass tape is still needed to

secure the battery. The supports are therefore not strictly

necessary to use at all, but they do provide extra lateral

support. I've also added the body posts, front bumper, and carbon

bumper support.

This model came with dish wheels but no tires so I've added a set of

cheap racing slicks to be consistent with my other TRF chassis

models. The completed chassis is shown at the right.

©2024 Eric Albrecht