Tamiya TRF 414X Project

Page 1: Unboxing

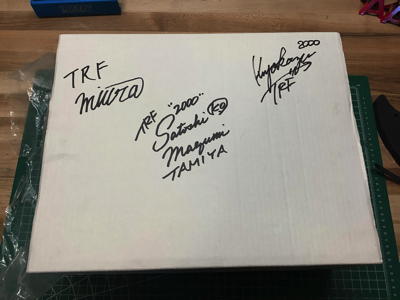

The "standard" TRF 414X (if any version of the model can be called

standard) apparently came in the black box shown on the left.

(This is not my photo; I found it on the Internet). This is the

version that would have been limited to 150 copies and sold only to

racing drivers in the US. The version I got came already assembled

from Japan in the hard case and box shown on the right. My copy

is signed by Tamiya TRF Team members Masayuki Miura, Satoshi Maezumi,

and Kiyokazu Suzuki. This version does not have a kit number (that

I could find), but based on the "2000" date on the box, this came out

after the limited production run of the 93013 kit in 1999. Since

there is no kit number and no information on production numbers I can't

estimate how many of these were made, but it is a safe bet that this

version is even more rare than the "standard" TRF 414X. Maybe this

is the only one?

My copy of the TRF 414X chassis came in this rare 49130 Tamiya Stealth

Box. This is a lockable hard case with foam liner. It has

the appearance of carbon fiber, but I would guess this is just a sticker

layer because otherwise the box alone would have cost a fortune.

There is plenty of room inside the box for the chassis with the setting

dishes as long as the body posts and bumper are not attached.

Those parts, along with the servo saver, spare hardware, spur gear,

spare springs, and plastic sprues are shown bagged on the right.

Also shown are the letter stickers and keys that came with the Stealth

Box. My chassis has clearly only ever been kept in this case and

never driven. It is in pristine new condition.

The first thing I did was disassemble the entire chassis and knoll out

all the parts like an old Tamiya catalog photo. This was quite

cathartic and allowed me an opportunity to marvel at all the unusual

parts, many of which are actually unique to this model. As far as I

can tell, virtually all of the carbon fiber parts are unique because

the later TRF 414 changed the upper and lower chassis plates and shock

towers.

High end Tamiya models typically use button head cap screws, but in this

case all of the screws which aren't countersunk have a larger standard

socket head. The black socket head cap screws are mostly 3mm

diameter and made from steel, while the flat head JIS screws which are

used on the bottom of the chassis plate appear to be titanium (at least

they are the right color for it and non-magnetic). The turnbuckles

shown on the right are unusual in that they use 6mm balls rather than

the much more common 5mm.

There are many different sizes of bearings and they vary from rubber

shielded to metal shielded depending on whether the are installed in a

protected internal environment or external and exposed to the

elements. There are a wide variety of aluminum spacers. The

CVD style drive shafts shown on the right use pressed pins so they can't

be disassembled.

The suspension arms are made from plastic (Nylon), but they

are not injection molded. You can tell that they were machined

from a solid block because the milling marks are visible on the surface

and there is no evidence of a mold parting plane. I don't know if

they did this for strength and resilience reasons or because it allowed

them to prototype dimensional changes more quickly. I'd guess the

latter. On the right you can see some of the machined aluminum

parts. This model predates the modern Tamiya blue anodizing, so

the parts all just look like bare aluminum. Even the pulleys are

aluminum with staked belt shields.

The shock parts are rather beautiful and also have some unique

features. As you can see on the right, they are only gold anodized

on the outside while the inside appears to be fluorine coated for

smoothness. There are 3 different spring rate options but only 2

copies of each spring. By default the soft springs are used in the

front and the hard in the rear with the gold medium springs

unused. Interestingly, this is not how my copy was configured in

the box. The shock bodies are not externally threaded for preload

adjustment, so that needs to be done with plastic spacers (thick and

thin in front, thick only in the rear).

In case you thought it wouldn't be economical to develop molds for such a

low production model, this label on the body posts shows that they were

made specifically for the 93013 kit in July of 1999. These body

posts carried forward into the later versions of the TRF 414.

This model does not come with a build manual in the traditional

sense. Instead, included are a small stack of loose papers with a

parts list and exploded views of various subassemblies. A sample

is shown at left. It is up to the builder to figure out the right

build order and to be smart enough to know what grease and oil to use,

where, and when. There is also a nice letter (in Japanese)

explaining a bit about this finished model and encouraging the buyer to

register it. I've included a redacted copy in both Japanese and

English on the right.

©2024 Eric Albrecht