Tamiya Ferrari F40 Project

Page 1: Assembly

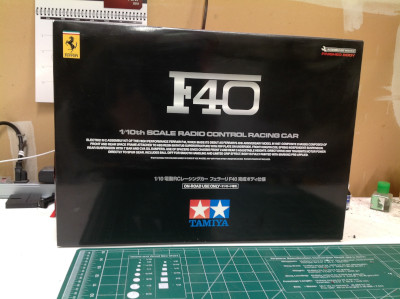

For such a pretty model, this kit comes in a very bland box. There

is no artwork at all on the box, just a plain black background with

some text. I don't know if this was a marketing restriction

related to the license with Ferrari or if there was something else

behind it. There are no blister packs inside but there are boxes

for the hardware and plastic parts and the finished body gets its own

slot. The body is finished just as perfectly as you would expect

from Tamiya.

Upon laying out the parts on the table, you can see that this is a very

simple chassis. There are few parts. There is quite a bit of

hardware though as you can see in the image on the right. In

particular the hardware related the rear axle includes part types I

haven't seen before.

This is the first model I have ever assembled using foam tires and I

didn't know what I was doing. The instructions are quite clear,

but only to a point. The tires are affixed to the smooth

cylindrical wheels using double sided tape. The idea is to have

only a small amount of adhesive exposed when you push on the tire, then

pull the backing off the tape once the tire in in place. This

worked fine for the rear tires, but for the front tires I found that the

tire squished as it was pushed on and was therefore not as wide as the

wheel. I tried to fix this by pulling on the tire but this only

caused chunks to break off the tire and cracks to form. You can

see some of the damage in the photo. It turns out it is OK for the

wheel to protrude beyond the tire. The tire should be pushed on

from the outside so it is flush on the visible edge, but the inner edge

doesn't matter. I paid the price for this mistake on my first run.

The steering on this car is about as simple as it gets. The

plastic servo saver attaches to the servo output spline, and the

steering tie rods link directly to that. No bellcranks. In

fact, the inner edge of the links don't even have rod ends. There

are Z-bends in the wire.

The front "suspension" can barely be called such. Each steering

knuckle has a single vertical steel rod used as a kingpin which is

retained with a set screw. A tiny spring sits on the upper side of

the kingpin.

The opening in the C-hub is bigger than the steering knuckle which

allows it to float up and down. This motion, and any flexibility

in the control arms, accounts for all the movement of the front

suspension. The arms are connected to a small front bumper and an

FRP lower plate.

The steering servo attaches to the base plate with a couple of little

plastic mounting blocks. As you can see on the left, the mounting

holes are slotted which allows you to adjust the servo side to

side. This helps you get a good mechanical center, useful in the

days before electronic sub trim.

Now we can attach the front suspension to the main chassis

bathtub. You can see the large open space available for

electronics and the lateral slot for an old style rounded battery.

From beneath you can see the FRP rear chassis plate. It is

connected by only two screws in a longitudinal line, mounted with rubber

o-rings. This allows the whole plate to rock side to side.

This movement along with flexibility of the plate is the rear

suspension.

This box houses the gear axle and gearbox (what there is of it).

The slot in the bottom makes room for the motor. The round

protrusion at the left is a bearing support. The ball at the front

center is for the single shock. Note that the shock doesn't do

anything to resist side to side motion. It only responds to up and

down motion which is driven entirely by bending on the rear base plate.

Here's the rear axle. This is a heavy duty shaft inserted from the

left. The plastic hub you see is locked to the shaft and screws

to the wheel. This model does not use hexes to drive the

wheels. The right hand end will serve as the support for the

differential and spur gear.

Now the stock Sport Tuned motor has been installed and I've begun

assembly of the ball differential. It uses only 6 small steel

balls carried inside the spur gear itself. These will be

sandwiched between raceway washers.

Now the spur gear has been slid over the axle. It helps to lay the

car on its side when performing this step to allow the axle to be

vertical. The other raceway and hub are then installed completing

the rear axle.

Finally, the single yellow CVA shock can be built and installed and then

the electronics. For some reason I see a standard silver can

motor in this picture, but I have no idea why. I used the Sport

Tuned motor for this build. The right hand image shows the

completed chassis with wheels, tires, and body posts. Note the

extreme width of the rear tires.

Here is the body just as it came out of the box. It has been

trimmed with no burrs, jagged edges, or wavy lines. The paint has

been applied with perfect masking around the windows. The stickers

have also been applied perfectly which is particularly impressive in

the area of the tail lights. My only minor complaint is that the

color of the rear wing does not perfectly match the color of the

body. In fact, it appears that the wing has not been painted as it is

just the color in which it was molded.

The difference between these two photos is subtle and represents the

only additional decoration I did to the body. I smoked the

windows. I didn't like seeing all the radio gear through the

window and the dark colored windows help obscure that.

The whole time I've been building, driving, and thinking about this car

I've been concerned that it is not to scale because it is way too wide,

presumably in order to properly fit the Group C chassis. To prove

this I found an overhead view of the real car and compared it to a photo

I took of the model. Looks like I was wrong; the F40 really is

this wide.

This shows the damage to one front tire after the first run. The

combination of cracking caused during tire installation combined with

the kingpin coming loose and canting the wheel caused a lot of

damage. The tire part number listed in the manual doesn't seem to

exist any longer, but luckily I found that the front tires for the F104

chassis fit just right, and now that I know how to install them I did it

properly.

©2019 Eric Albrecht