Tamiya Porsche 959 Project

Page 2: Assembly

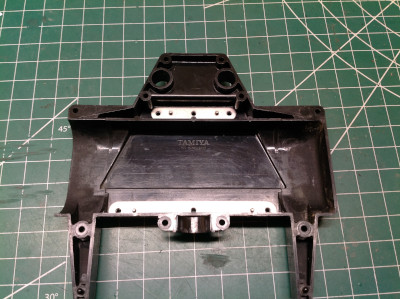

Assembly begins by installing a pair of sheet metal reinforcing braces

as shown on the left. The bulk of the plastic chassis part shown

acts as a battery compartment. At the time, pretty much all

batteries were the same size and shape so a vintage or NiMH battery

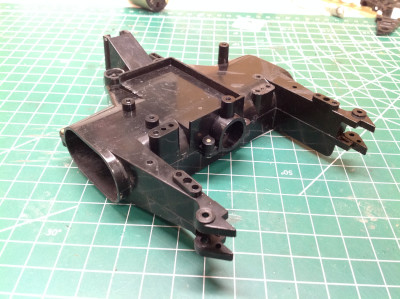

really needs to be used with this model. On the right you can see

the battery slot has been covered with the mating half of the

chassis. I wouldn't really call this a bathtub chassis. I'm

not sure we have a good name for this style since it is not shared with

any other Tamiya chassis. This was in the days when most of the

screws were still self tapping JIS style.There is no hex hardware in

this model. A total of 10 screws are used to join these two halves

together.

The dual bellcrank steering seems to be made from PA and incorporates an

integral servo saver. The spring and collar shown are used to

adjust the slip torque on the servo saver. The bridge is not

actually screwed to the cranks, instead it is trapped by the chassis

after installation. There are no bearings on the cranks, instead

they just rotate inside slots in the chassis halves. This means that the

shafts and bore are wear surfaces.

The manual shows that the original kit came with two gearing options: a

41T spur with a 16T pinion (2.56:1) or a 40T spur with an 18T pinion

(2.22:1). The higher speed gearing is intended for pavement and

the lower speed gearing for off-road use. My copy only came with

the low speed gearing which is probably the safer of the two to avoid

damage. There is a bevel gear integral to the spur gear as

shown. Because the motor is mounted longitudinally in this

chassis, the spur gear connects to the drive shaft to power the front

axle directly, and the bevel gear will lead down to the rear

differential. The thrust bearing shown on the right isn't

something I've seen Tamiya do before. Unlike spur gears, every

bevel gear set produces thrust loads as a consequence of the tooth

separation forces. Usually these thrust loads are effectively

ignored in RC chassis design, but in this case a thrust bearing and a

pair of thrust washers sit behind the gear to react these forces and

minimize rotating friction. Nice! On the other hand, this

shaft uses a 5x8 ball bearing at one end but only a plastic bearing on

the other end. Why?

Here the main shaft has been installed in the rear gearbox

housing. The little sheet metal clip grips a slot in the shaft and

keeps it from sliding out axially. That orthogonal shaft you see

in the left hand picture is one of the drive cups that I couldn't

remove.

Now the differential bevel gears can be slid over the splines on the

drive cups as shown on the left. These are the first metal gears

used in the kit. On the right you can see how the internals of the

differential are built up. The differential ring gear houses the

two metal spider gears which are inserted from opposite sides and rotate

on steel pins. The counter gear is also shown, and rides on

plastic bearings. I found it quite odd that Tamiya went to all the

trouble of using a thrust bearing to minimize friction on the bevel

gears, but then also used useless plastic bearings on high torque

rotating parts.

Here the rest of the gears have been installed in the rear gearbox

housing. The spur gear drives the counter gear through a set of

bevels, then the counter gear drives the ring gear of the

differential. After the gears have been lubricated, the gearbox

halves are joined together with only two machine screws which thread

into nuts for extra strength. The two white parts shown attached

on the right are adapters to connect the gearbox to the rest of the

chassis.

These rear lower suspension arms certainly don't look like traditional

wishbones. They are very wide and basically rectangular. In

the photo on the right I've actually installed them backwards.

That "horn" sticking out should be on the inboard side and will serve as

a down stop. The upper arm is just a straight link that sits all

the way at the back.

The rear uprights originally used plastic bearings but I replaced them

with ball bearings. The white parts attach to the uprights and

serve as the lower spring perches. The springs are separate from

the shocks which will attach to the lower arms later. The axles

are dogbone style. If you look closely at the picture on the

right, you can see the two pieces of vinyl tubing that protrude from the

back of the gearbox and contact the horns on the lower arms to act as

down stops. This gives the suspension a bit of cushion when it

hits the stop and prevents the shocks from bottoming.

Here are a couple of pictures of the completed rear gearbox. The

picture on the right illustrates the total amount of suspension travel

which is pretty significant. You can also see the large change in camber between extended and compressed.

The 959 kit came with a legendary Technigold motor out of the box, one

of the only models ever to do so. This 21T motor might seem a bit

tame by modern standards, but it was more than adequate for this little

1/12 scale rally car. The picture on the right shows the white

rings which serve as motor mounts. This motor connects to the

chassis in a way different from every other model I've seen. No

screws bolt it to the chassis.

The motor plugs into the slot in the rear gearbox as shown. You

can't see the gear mesh and also can't do anything to adjust it.

You are relying entirely on the parts lining up. Only two vertical

bolts connect the chassis to the rear gearbox as shown on the

right. The motor is sandwiched between the two which is all that

holds it in place. So what prevents the motor from spinning in

place? There is screw head on the pinion side of the motor that

protrudes slightly. It fits into a slot on the gearbox that you

can see if you zoom into the picture on the left. The motor also

effectively serves are the retainer for the suspension pins you see in

the same picture.

One nasty surprise I found is that the previous owner took a razor saw

to the right side of the chassis for some reason and sawed off one of

the MSC support and one of the servo supports. He kept the removed part

and then used it as a spacer. This is invisible when the MSC is

installed so I didn't know about it until now.

Time to start on the front gearbox. While the gearbox housing is

quite a bit smaller than the one in the rear since there is no motor

attachment, the basic internals are the same. We start with

another bevel gear with a thrust washer behind it just like in the rear.

Next we can install the front differential which is also identical to

the one we already built for the rear. The addition of a counter

gear between the input and the differential ring gear reverses the

rotation so that the axle will spin the right way even though the input

points backward. The counter gear has no impact on the

ratio. You can see how full this housing is. There is no

extra space.

Now we can start working on the front suspension. The lower arms

are the weakest part of the chassis design and the most prone to

failure. The problem is that the pivot balls for the lower shock

supports are cantilevered from the lower arms. Those mounting

holes have very little material around them which, coupled with the fact

that the pivot ball stretches the hole when threaded in, produces a lot

of stress. Mine were actually in good shape when I got the model

but I found them cracked a month later just from sitting on the

shelf. The metal kingpin balls are molded right into the

knuckles. These balls are then captured by split spherical plastic

bearings that get clipped into the suspension arms. It is a

complicated setup full of unique parts. The axles are dogbone type

and the pivot pins are unthreaded.

Here is the completed front suspension and gearbox assembly. On

the right you can see the modular nature of the chassis.The front and

rear gearboxes are separate from the center chassis which serves as a

bridge and electronics container. The motor is sandwiched between

the chassis and rear gearbox.

The front gearbox installs by sliding into a slot on the chassis as

shown. This makes for very easy removal. A single screw

installed laterally secures the joint.

This picture shows the very significant caster angle on the front

hub. The straight vertical section on the front on the steering

hubs acts as a steering travel stop.

The drive shaft needs to be installed when the gearboxes are

attached. There was apparently a running change to this component

during production of this model. Early copies used dogbone style

ends while later copies (like mine) used a flattened end. The

steering links have also been installed at this point. They use

straight threaded rods, not turnbuckles.

This view from the bottom shows the steering system which is still

exposed at this point. The front bumper serves as an undertray and

protective shield for the whole front of the chassis. A similar,

wider tray does the same for the rear.

The shocks are tiny, unique, and tricky. These are real aluminum,

oil filled shocks but at a scale different than all other Tamiya

models. The first thing to note is that the gland cap is swaged

onto the cylinder and therefore not removable. According to the

cross section in the manual, there are two o-rings in there but there is

no access to them for replacement. The piston is a solid metal

ring with no holes or slots, so the rate orifice is just the clearance

between the piston and the cylinder. Bleeding these shocks takes a

very long time because it is so difficult for air bubbles to escape

past the piston. Note also that the rod continues past the piston

head but with a smaller area than the threaded end due to the flat on

one side. More on this feature later. The front shocks are

coilover type which mount vertically to a cross bracket as shown.

The rear shocks work essentially the same except that they have no

integral spring and the mounting bracket employs a 90 degree bend.

Most shocks have different fluid areas on either side of the piston

head. On the head end the area is the entire inner diameter of the

cylinder while on the gland end this area is reduced by the area of the

rod itself. This means that when the shock compresses, the

internal volume of the shock reduces and the extra fluid needs somewhere

to go, a phenomenon called volume compensation. If there is no

outlet, this results in a hydraulic lock and the shock cannot

compress. Most Tamiya shocks use a hemispherical

bladder inside the head end cap for volume compensation but these shocks

do something different. Firstly, because there is also a rod on

the back side of the piston, the difference in internal volume between

the extended and compressed states is very little. It amounts to

only the volume of the flat on the rod. This means that very

little fluid needs to be forced out of the shock to compress it.

However, this flat serves another function: dual rate damping.

When the shock first starts compressing, the fluid squeezes past the

piston and then out the head end port. The extra volume serves to

swell the diameter of the plastic tubing on the cap (not yet

installed). As the shock compresses further, the rod actually

extends inside the outlet port on the head end of the shock, partially

blocking it. This results in a reduced outlet orifice effectively

snubbing the shock. Genius!

Here the shocks have been installed on the chassis. Note the

unusual arrangement of the rear suspension. The springs and

dampers are installed separately. The dampers sit behind the

suspension arms while the springs sit slightly forward of the

axle. Note that the spring upper perch is a cantilevered bracket

that also acts as a body post. This is the second weakest part of

the chassis. These brackets can crack quite easily. On the

other hand, because the dampers and springs have been separated, the

pivot an the arm does not need to support the weight of the vehicle so

the rear arms are less likely to crack than the front arms. No

matter what breaks, it is going to cost you. Aftermarket aluminum

or Delrin arms are available, as are coilover rear shocks.

At this point a large plastic plate that the manual calls a "practice

bumper" can be installed. Ideally this would be removed for scale

realism. The second "inner bumper" is made from a much harder,

heat resistant materal (G-10?) and holds the resistor. That metal

bracket you can see over the motor stiffens the whole chassis. The

front body posts have also been installed.

The 959 chassis does not use, cross pins to drive the wheel hexes, it

uses splines like the Clod Buster (which actually came out later).

The hexes are 10mm instead of the much more common 12mm which limits

wheel choices. On the right I've also added the steering servo

link.

Here's the mechanical speed controller that I tried to clean up and

getting working as smoothly as possible. Naturally I spend a bunch

of time studying the current paths to figure out how it worked.

I would normally upgrade a vintage model to modern electronics for

runability, but in this case I decided to stick with the classic

electronics that came with the model. There were two identical

analog servos and an AM receiver. Note that this model has no

place for a radio battery pack, so you need to use a receiver with a

built-in BEC. Nobody really makes these anymore since BECs are now

part of the electronic speed controller. The completed model is

shown on the right with all electronics installed. It is fully

ready to be tested at this point.

Here I've put on the wheels and tires and attached the body. This

allowed me to get out an run the model to see how I liked it. I

attempted to restore the flexibility of the tires with glycerin and was

partially successful, but they remain pretty stiff. I also did not

have any oil in the shocks at this point because I was waiting for

delivery of gasket material and tubing. This also negatively

impacted the handling.

These final two pictures compare the chassis as I received it (left)

with what I ended with after cleaning and restoration (right). The

improvement may not be immediately obvious, but every single part was

touched and addressed.

©2022 Eric Albrecht