TW-715 Project

Page 4: Building the Axles

The axles come pre-assembled in the box which theoretically means you

don't need to re-build them. I can't abide anything I didn't build

myself so I completely tore them down and it's a good thing I did

because there were a number of problems. The instruction videos

have no content at all for the axles; they just assume the axles are

already assembled. This means you are on your own figuring out how

they come apart, function, and go back together. I photographed

the front axle as it came out of the box for reference as shown on the

left. Disassembly took over an hour primarily because of the

threaded kingpin bushing shown on the right. Some of the bushings

had flats on them as shown which made it easy to grab them with a wrench

and remove the mating bolt. One of them did not have flats so I

had to try to hold it with a needle nose pliers which would have been OK

if not for the fact that this particular mating bolt was so slathered

with thread lock that it wouldn't turn at all (zoom in to see the

compound remaining on the threads). I ended up brutalizing the

bushing getting it apart. Luckily it will be completely hidden

once re-assembled.

Here is the complete set of parts from a dis-assembled front axle

(left); at least 84 parts not counting sub parts of the universal joints

or tie rods. On the right you can see the parts for the locking

differential assembly, 5 of which are large bearings. The brass

diff housing has the dogs which will mate with the steel driving ring to

lock the diff when engaged. There are 4 spider gears in the

differential which seem pretty small for the weight of this truck.

Here's hoping that they hold up to the stress. The ring gear has

34 teeth and the pinion has 14 teeth so the axle ratio is 34:14 = 2.43:1

for a final drive ratio of 37.5:1 in low gear. This is not

particularly low for a truck of this size, making it more of a trail

truck than a rock crawler.

It's pretty dark down inside that differential housing so you can't see

much, but rest assured there's an output gear down there. The

picture on the right shows the spider gears installed. The grease

that you see was present already from the factory so I didn't need to

add any here.

Here is the pinion gear installed into the housing, ready to accept the

differential. This is a very complex machined part, but not very

precise as we're about to discover.

The picture on the left shows the differential assembly dropped into the

housing. On the right hand of the assembly is the locking ring

which is preloaded away from the differential with a small compression

spring. In the right image you can see the locking fork

installed. The upper right of the fork has a small horn with a

cable installed (facing away from the screen). When the cable is

pulled, the the crank rotates the fork and forces the locking ring to

the left, compressing the spring. The locking ring is keyed to the

right hand axle, so when it engages with the differential housing it

prevents relative motion and effectively locks the diff. In

theory.

I added the differential cover and figured I better try out that cable

actuated diff lock. Nothing. The cable wouldn't move at

all. I tried the still assembled rear axle and found exactly the

same problem. The diff locking mechanism was completely

non-functional from the factory. I tried loosening all the bolts

on the diff cover and all of the sudden it worked fine. I could

now pull the cable and feel the spring compress, engaging the locking

function. The problem, as it turned out, was that the recesses machined

into both the diff housing and cover had too small a diameter which

resulted in a mild interference fit with the pins on the locking

fork. This meant that as soon as things were clamped up there was

no clearance for the fork to rotate. I had to use my Dremel to

manually grind away some of the material (circled at right). It

was an all afternoon affair trying to get it to work right without

mutilating the parts too badly, but it fixed the problem and will be

hidden once assembled. I could have also solved the problem by

reducing the diameter of the pins on the locking fork (which I tried),

but they were too small for me to effectively sand or grind, so opening

up the housings was the only option.

Now that the diff locker is working properly I can start the rest

of the axle assembly. On the left I've inserted the axle housings

which fit into triangular slots on the diff housing. Note that

they are vastly different lengths because the differential is off

center. On the right I've also added the spring perches and lower

link mounts.

Now I've inserted the axles which have integrated universal

joints. You can see that the C-hub has no kingpin

inclination. On the right I've added the steering knuckle which

required re-installation of that mangled bushing from earlier.

Looks fine and, more importantly, works fine.

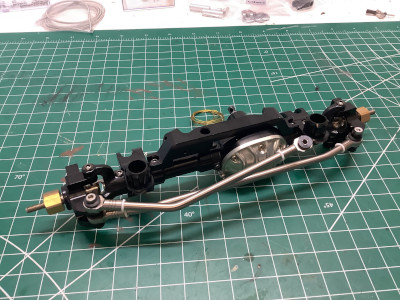

Here I've installed the stiffening truss which incorporates the upper

link mounts. On the right I've also added the steering link and

drag link in front of the axle. This would normally result

in reverse Ackerman geometry, but this model correctly locates the

steering link attachments outboard of the kingpins which

compensates. Good job again!

Done. Now let's compare the assembly as it came out of the box

(left) to my rebuild (right). Do you see the difference?

Neither did I. It wasn't until a month later when I powered it up

for the first time that I realized the front and rear wheels were

rotating in opposite directions meaning one or the other of the

differentials was installed upside down. It was the front.

It is hard to even see in these images, but pay attention to where the

cable comes out of the differential and you can see that it moved to the

other side of the pinion after my rebuild. It took me quite a

while to fix this.

I had originally planned to only rebuild the front axle since the rear

axle would be pretty much the same thing, but after the problems I found

I assumed modifications would be needed in the rear as well. I

was right. Oddly, even though the front differential was nicely

greased, the rear differential ended up being completely dry

inside. I added some grease and put it back together.

The rear locking mechanism required exactly the same grinding procedure

as the front to get it to operate smoothly. After that was done I

started adding the axle tubes. This differential is not as

obviously off center as the front, but the tubes are still slightly

different length so I had to pay attention to get it right.

Unlike the front axle, the rear axle uses separate parts for the

spring perches and lower link mounts. The springs are quite a bit

further inboard here. On the right I've also added the truss,

completing the rear axle assembly.

Here are the suspension links which appear to be titanium.

Interestingly, the kit came with a full package of plastic rod ends and

metal balls, but none of them are used by default. These metal rod

ends use rubber inserts and straight spacers instead. Without the

ball joints these rod ends have less rotational capability than the

plastic parts would, but it seems to be enough for full suspension

articulation. On the right I've installed the upper links on the

front axle as well as the brackets that will attach them to the

chassis. They are well triangulated.

Now the front axle can be installed onto the chassis. We start by

sliding the drive shaft halves together and then bolt the upper link

brackets to the frame. On the right I've added the brackets for

the lower links which connect to a frame cross member. The upper

links end up having almost no triangulation. Ideally there would

have been a panhard bar to help with lateral motion.

This vehicle does not use coilover shocks. The damper and spring

are totally separate components with different mounting locations as

shown on the left. I really like this arrangement. On the

right I've connected the drag link to the steering servo. Note

that the instruction video shows a clamping servo horn with multiple

holes which is different than what actually comes in the kit. It

is still a nice metal horn though.

The rear links connect quite differently. Both the upper and lower

links connect to the same bracket and actually cross over each

other. This results in considerable triangulation for all

links. The installed rear axle is shown on the right. The

link brackets attach to the rear frame cross member.

Finally, the rear springs and shocks can be attached to complete the

installation of the rear axle and the entire chassis assembly.

At this stage of the build it was possible to make a rolling chassis and

actually try out the model with minimum functionality so I had to skip

ahead and assemble the wheels (left). The metal beadlock wheels

use an inner spacing ring, a primary wheel part, and a locking

ring. There is also a hub to cover the wheel nut. The 8

countersunk silver screws you see on the back of the wheel are what

actually lock the bead. The 25 tiny cap screws around the

perimeter on the front are just for show. There are also 8 cap

screws to hold on the hub. The inner foam is quite stiff and is

ribbed as shown. The tires are perfect scale examples of NDT

(non-directional tread) military tires used on the real truck

(right). These are 9.00-20 tires from STA (Specialty Tires of

America). This means they fit a 20" wheel and are 9" wide at the

tread. Tires of the early 1960's were generally made with a 90%

aspect ratio, but these are a bit taller with an overall diameter of

over 40". The model tires are a very good match.

©2022 Eric Albrecht