Features

|

|

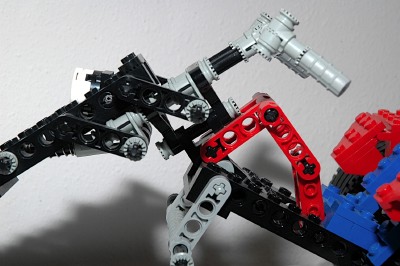

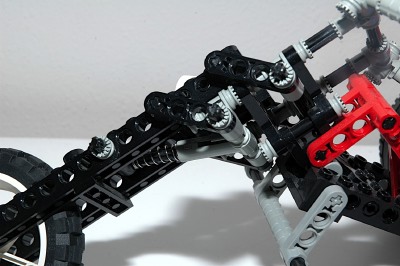

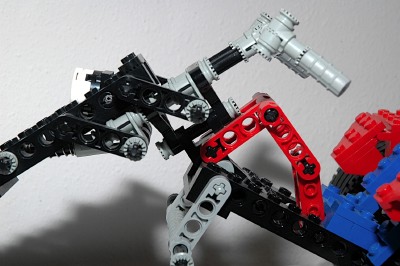

Steering

The front fork can be steered using the handle bars which are

constructed of toothed connectors and axles. The fork

pivots around an axle which passes through the head tube

part. A pair of triangle parts are used as triple trees.

The handlebar angle and is fixed using toothed

connectors. The fork rake angle is set by the head tube. As

you can see in the computer image, the rake angle is further increased

by placing the head tube at an angle using crankshaft elements.

Like a real chopper, the rake angle is very extreme which requires a

very large turning input to get a reasonable turning radius and results

in riding on the side of the tire.

|

LDraw file courtesy of Benjamin Wendl.

Click for an animation of the

steering in motion.

|

|

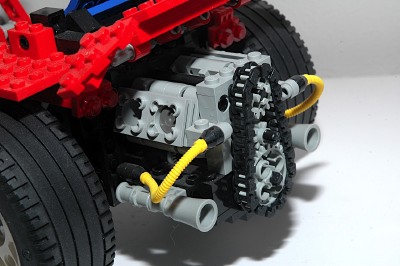

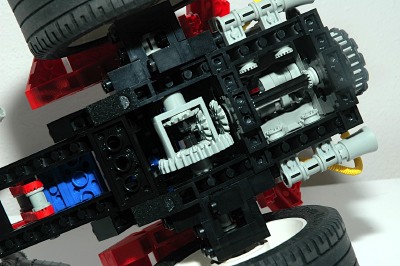

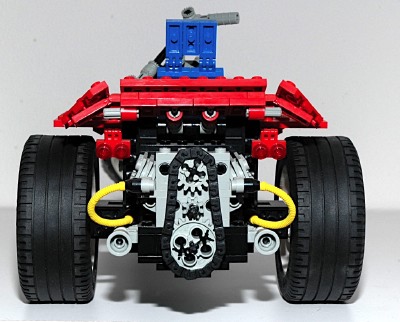

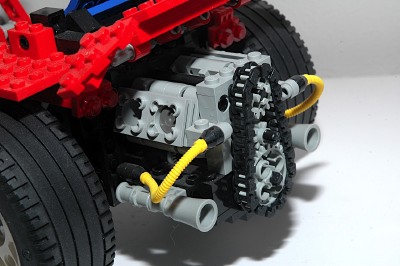

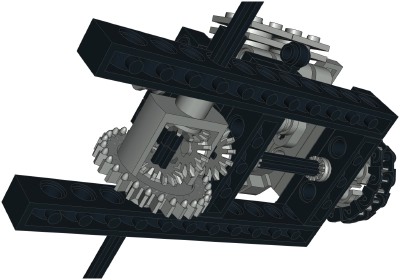

Engine

The V-4 engine is made from cylindrical engine elements and is located

under the seat between the rear wheels. It is driven by the

differential. The 28 tooth ring gear drives a 14 tooth bevel

gear. Next a 24 tooth spur drives an 8 tooth pinion connected to

the crankshaft, resulting in a ratio of 6:1.

The crankshaft is

offset 1/2 stud from center, giving the pistons a stroke of 1 stud.

There is also a chain which runs between the 24 tooth gear at the

bottom and a 16 tooth gear on the top. This top axle does not do

anything but presumably represent a cam shaft.

|

LDraw file courtesy of Benjamin Wendl.

Click for an animation of the

engine in motion. |

|

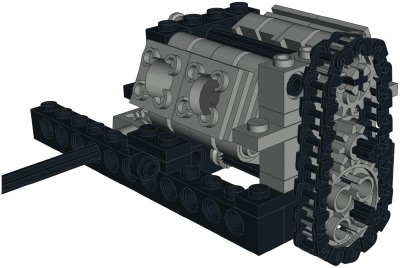

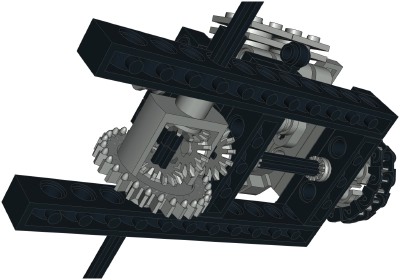

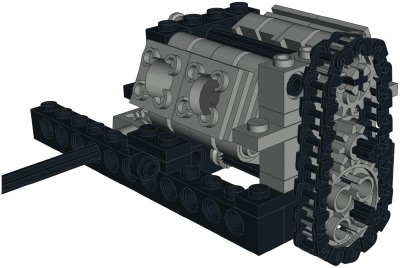

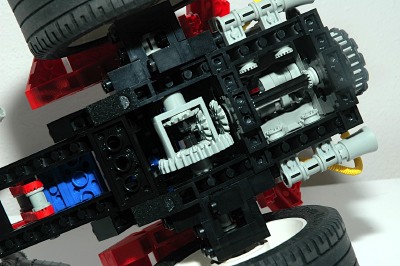

Differential

There is a differential gear between the two main wheels to allow for

easy turning on a powered axle. The diff

incorporates a built-in 28 tooth ring gear which can work either as a

bevel or a spur, similar to the 24 tooth crown gear. It is made

to house 3 of the 14 tooth bevel gears. One is on each axle,

and one planet gear in the middle allows the axles to turn at different

rates. |

LDraw file courtesy of Benjamin Wendl.

Click for an animation of the

differential in motion.

|

|

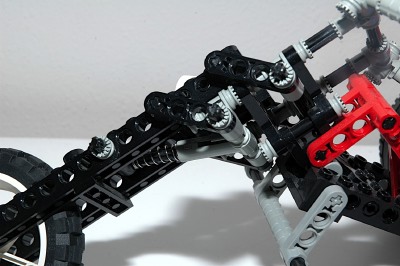

Suspension

The front suspension is a girder type. Instead of having

compressible fork tubes, the forks are actually rigid. Instead a

4-bar linkage is formed between the forks, the triple trees, and some

1x4 side links. A spring at the bottom of this mechanism supports

the weight. As front brakes are applied, this type of suspension

will cause the wheelbase to shorten and the forks and headlight to move

upwards toward the handlebars.

|

LDraw file courtesy of Benjamin Wendl.

Click for an animation of the

front suspension in motion.

|

|

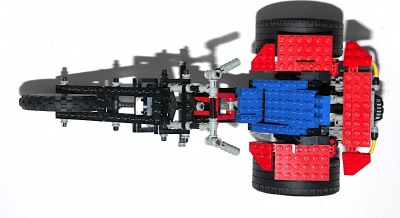

Wheels and Tires

The front wheel is the same motorcycle wheel which had been used in the

previous bikes 8838. It's large diameter

and narrow width make it an ideal front tire.

The rear wheels are enormous, wide, and flat. They are clearly

far too complex to have been designed for this motorcycle, a fact which

would be confirmed in 1994. Only two

models ever used these wheels. The center hole in the wheel is

actually round and does not have a cross slot, so it does not grip the

axle. If you look closely you can see that there is a bushing

inside the hub. Ever since its introduction in 1977, the bushing has had 4 flanges at one end

which allows it to be placed in-between studs on a plate. This

capability was rarely ever used. In this case, those same flanges

grib tabs on the wheel hub which locks the wheel to the main axle.

|

|