Features

|

|

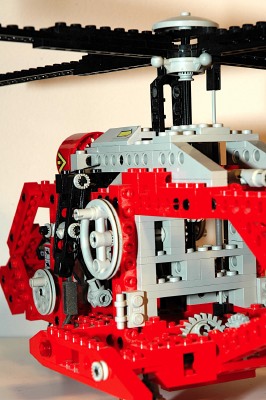

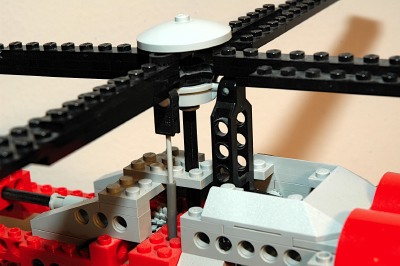

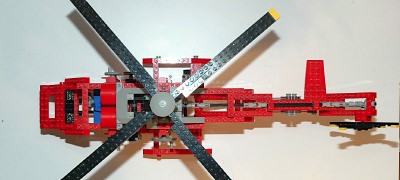

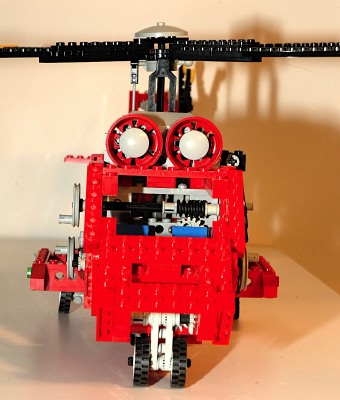

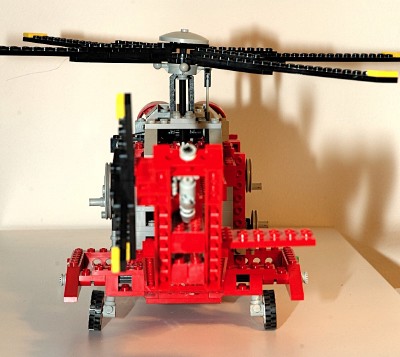

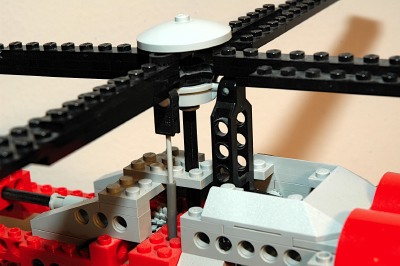

Rotors

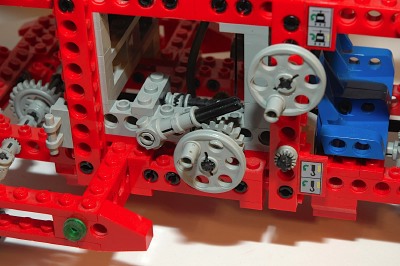

The rotors' rotation is driven by an input crank on the left

side. This crank drives a set of 14 tooth bevel gears giving the

main

rotor a ratio of 1:1. The crank axle also drives a set or gears

made up of a 24 tooth crown mating with two stacked 14 tooth bevel

gears (one of the rare places this pairing is made) which passes torque

along the length of the boom to the

tail through 3 universal joints. Here another set of 14 tooth

bevel gears drives the 4 blade tail rotor.

A pair of simulated turbine engines are nestled beneath the main rotor

head.

|

Ldraw file courtesy of

Benjamin Wendl.

Click for an animation of the

rotors

in

motion.

|

|

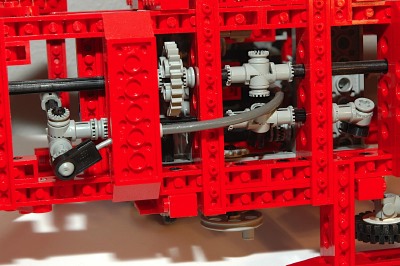

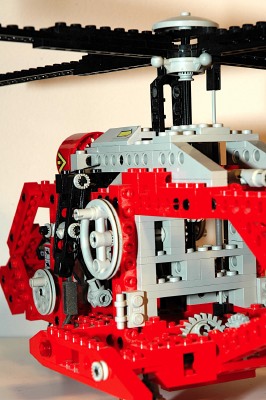

Cyclic Pitch

A number of new parts made a simulated cyclic system possible.

Real helicopter cyclic works by changing the pitch of individual blades

as they rotate using a swashplate. For example, the leading and

trailing blades may be at 10 degrees of pitch, while the port and

starboard blades are at 5 and 15 degrees respectively. This model

pivots the entire rotor head instead. If a real helicopter did

this it would risk striking the rotor against the frame.

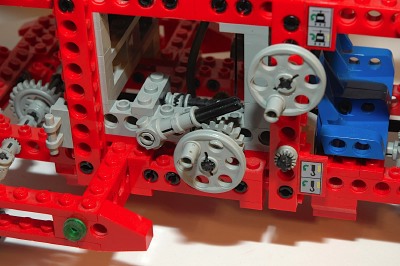

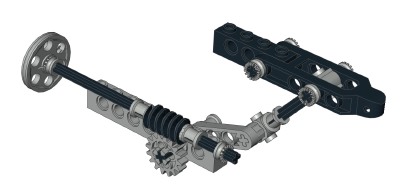

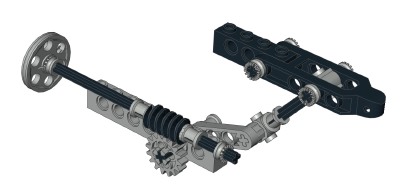

The rotor axle drives a spherical ball gear. A part with 4

ball joints which is similar to a swashplate connects to a pair of flex

cables to allow the head to pivot on two axes. The ball joints

also keep the swashplate from rotating. Inside the swashplate is

a four blade rotor part. The rotor has tabs on the inside which

mate with the ball gear to transmit torque. Because of the

shape of the gear, the rotor can pivot on two axes while still rotating.

The control of the cyclic is from a stick at the pilot's

position. There is one flex cable and sleeve for each axis.

Fore-aft motion of the stick pushes and pulls the cable using a ball

joint. The flex cable runs up to a link which lifts the

swashplate using a suspension control arm! Lateral motion of the

stick rotates an axle which runs aft. At the end of the axle is a

ball joint which connects to another flex cable. This flex cable

attaches to a ball joint on the side of the swashplate.

|

Ldraw file courtesy of

Benjamin Wendl.

Click for an

animation of the cyclic

in motion. |

|

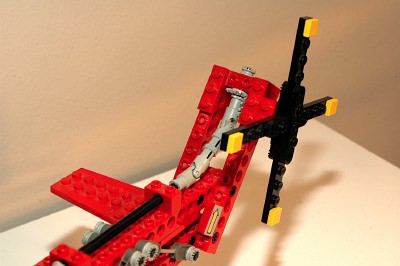

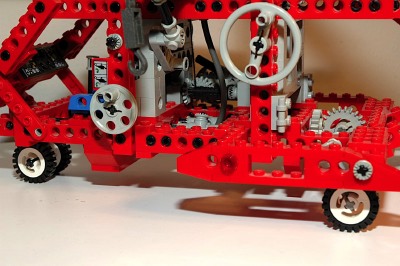

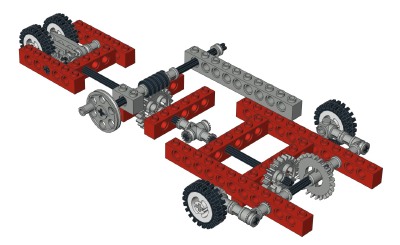

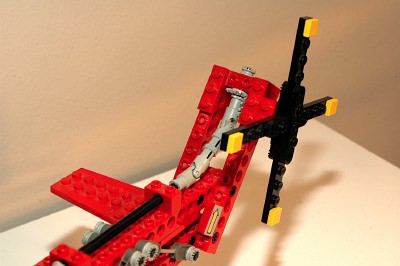

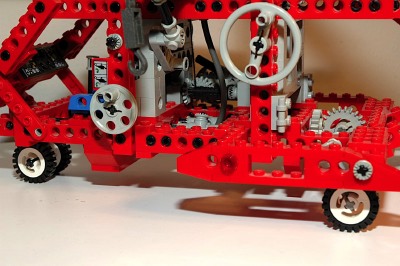

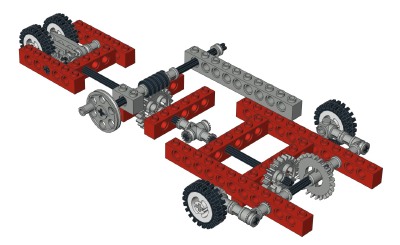

Landing Gear

The 3 point landing gear retracts using another crank on the port

side. The crank turns a worm gear which mates with a 24 tooth

spur gear. The spur gear drives an axle which runs both forward

and aft. The nose gear retracts forward via a set of 14 tooth

bevel gears. The main gear pivots forward via a 24 tooth crown

and spur gear. The final gear ratio is 24:1.

Each gear pivots a little over 90 degrees. In both the extended

and retracted positions the gear rests against a hard stop.

|

Ldraw file courtesy of Benjamin Wendl.

Click for an animation of the landing

gear in

motion.

|

|

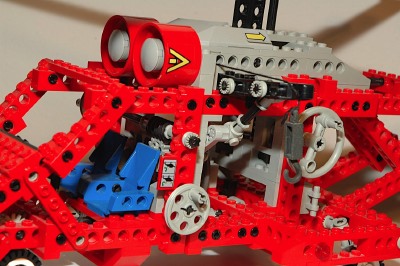

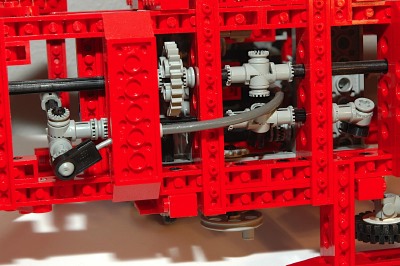

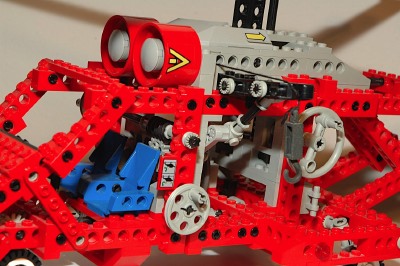

Rescue Winch

A pair of cranks on the starboard side operate the rescue winch on the

port side.

The first crank turns a worm gear which drives a 16 tooth spur

gear. The next axle pivots a lift arm which deploys the winch

boom.

The second crank attaches to a 16 tooth spur gear used as a ratchet

plate. A set of 14 tooth bevel gears drive the second axle which

works as a cable drum. The cable runs out to the winch and

attaches to a metal hook.

|

Ldraw file courtesy of Benjamin Wendl.

Click for an animation of the winch

boom deploying.

Click for an animation of the

cable in motion.

|