Features

|

|

Steering

The rear wheels can be steered using an overhead control or a steering

wheel in the cabin. This is the first Technic model to combine

both steering inputs. (The

8846 Tow Truck had a backdriving steering

wheel but it could not actually be used to steer the vehicle because

the belt would slip.)

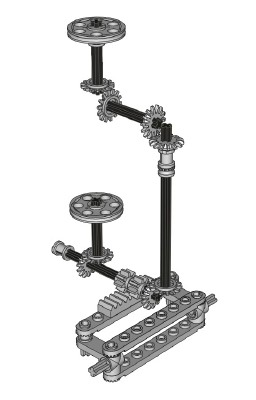

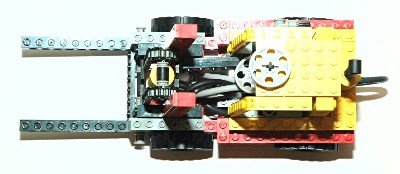

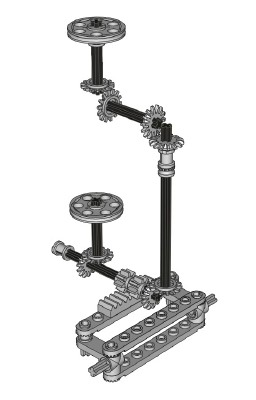

The path from the overhead control to the wheels is quite convoluted to

hide the axles. The overhead control drives an axle connected to

a pair of 14 tooth bevel gears. The second axle drives

another set which runs vertically down the aft of the cabin.

A third set of bevel gears drives a rack via a pair of 8 tooth pinion

gears. The steering mechanism itself uses the new control arms

and toothed links as shown in the computer image.

On the other side of the steering rack, on the same axle as the pinion

gears, another pair of 14 tooth bevel gears drive the steering wheel in

the cabin.

|

Click for an animation of the

steering in motion.

|

|

Pneumatics

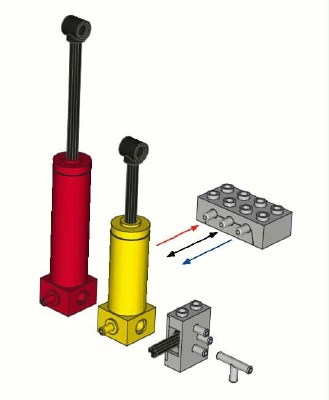

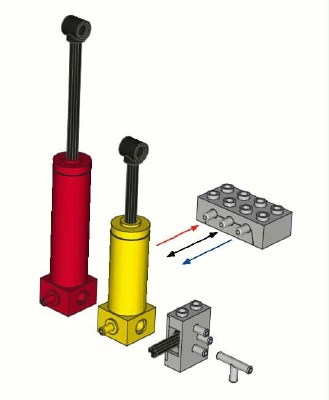

This model contains a single acting pneumatic system. The components of

this system are connected with rubber tubing routed through the holes

in the beams.

A single pump provides air pressure. Depression of the piston

produces positive pressure, and raising the piston produces negative

pressure (suction), limited by atmospheric pressure.

The pressure is fed to a distribution block with an input (pump) and

two outputs (switch). One output has a check valve which flows

out and the other a check valve which flows in. Each of these is

routed to a different inlet of a selector valve (switch) with one

output. Selection of the switch in one direction therefore allows

pressure output, while selection in the other direction allows suction.

Finally, there is a pneumatic actuator which has a port at the head end

to accept input from the switch. Positive pressure extends the

piston, while suction retracts it.

This model has the long stroke (64mm) pneumatic actuator which is only

found in two models.

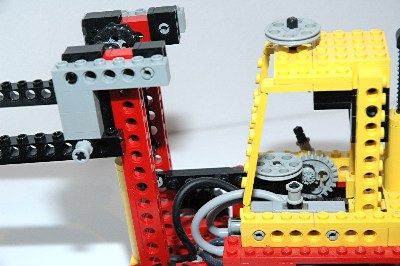

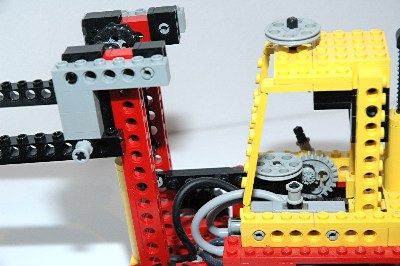

In the picture, the actuator is on the left, the selector valve is in

the middle, and the pump is on the right. The distribution block

is not visible.

|

|

|

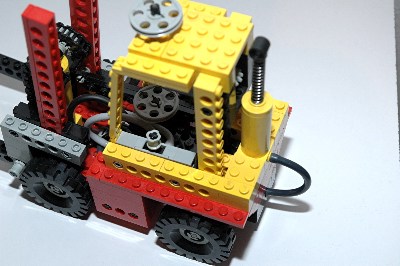

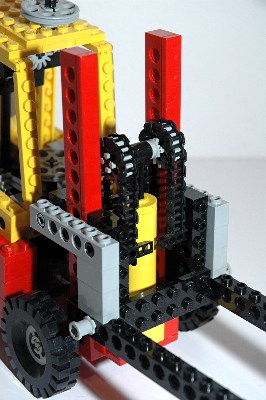

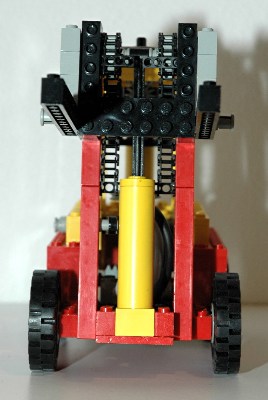

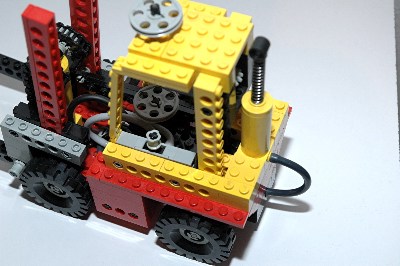

Forks

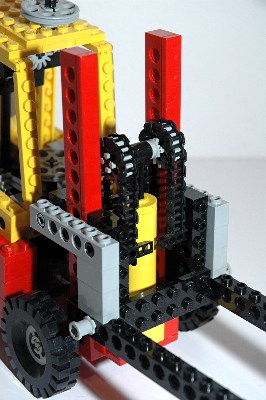

The forks can be raised and lowered using a pneumatic actuator.

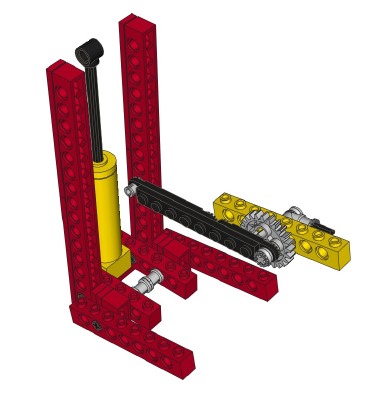

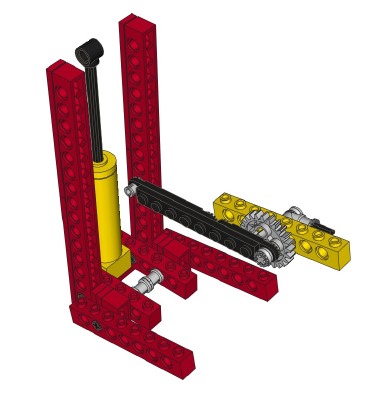

The actuator does not drive the forks directly, but drives a pair of

chains via two 16 tooth gears used as pulley wheels. One end of

the chains is fixed to the vertical structure via a long chain link

(track), while the other end is attached to the moving forks (see

picture). Since the chain doubles back on itself, the chain has

to move twice as far as the pulleys to which it is attached. The

effect of this (a reverse pulley system) is that the forks can raise

and lower twice the distance of the stroke of the actuator.

When retracting, the actuator does not really pull the forks down, it

only lowers the pulley, removing the force which holds the forks

up. The forks must descend under their own weight, which works as

long as there is no binding in the system.

The moment created by the cantilevered weight is

reacted by a force couple: the upper forward load is reacted by a

set of tiles on the back of the vertical structural assembly, and the

lower aft load is reacted by contact of the

lower tiles against the vertical structural assembly. This use of

tiles on both sides makes the motion of this forklift quite smooth,

among the best of all the Technic forklifts.

|

Click for an animation of the forks

lifting.

|

|

Fork Tilting

The entire fork and lift assembly can also be tipped forward to aid in

picking up a pallet from the ground (or dumping one on someone's

head). A lever on the right side made of a toothed connector

turns a 24 tooth gear used as a crank. A series of linear links

attached to the crank connect to the vertical structural assembly which

pivots about an axle on its base.

|

Click for an animation of the forks

tilting.

|

|

Wheels and Tires

This set uses four rubber 17x43 tires and standard old gray wheels.

|

|