Features

|

|

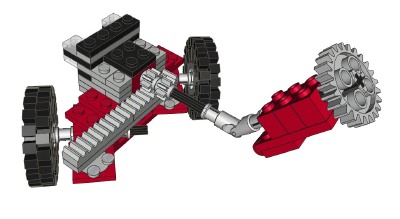

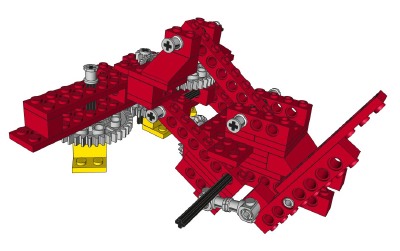

Steering

The front wheels can be steered using a wheel made from a 24

tooth gear at the driver's

position. As can be seen in the computer generated image, the

wheel drives an axle connected to a pair of 8 tooth pinion gears via a

universal joint. The pinions

drive a pair of racks. The steering mechanism itself uses 6

traditional 2x2 swivels with 2 pair allowing rotation of the wheels

about the vertical axis and another pair acting as control arms

attached to the rack gears. Simple axles allow the wheels to

rotate freely.

|

Click for an animation of the

steering in motion.

|

|

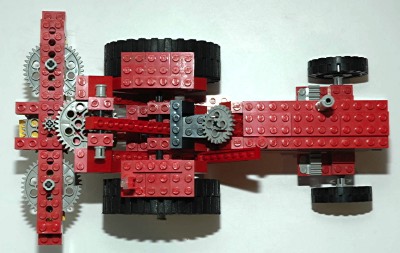

Implements

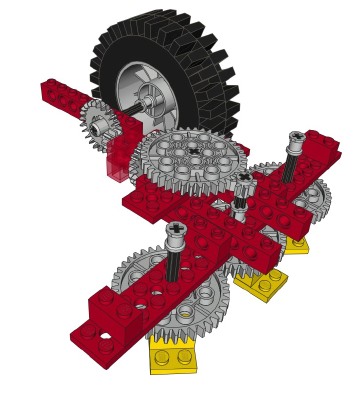

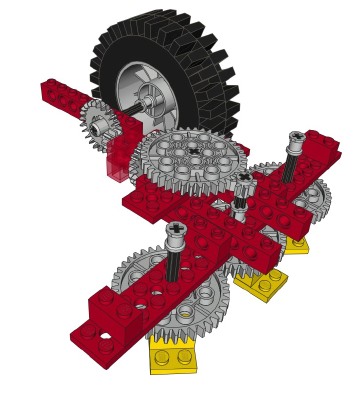

The right rear wheel of the tractor drives a PTO (Power Take Off) via a

bevel set using an 8 tooth pinion and a 24 tooth crown gear. This

gives the PTO a gear ratio of 3:1. The left rear wheel is not

connected to this mechanism.

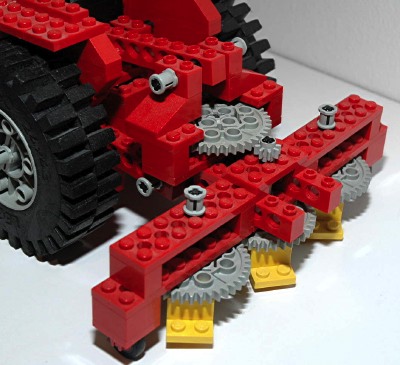

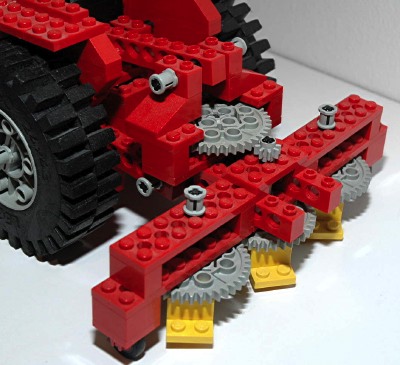

The implement for the primary model is a thresher. The PTO drives

a 40 tooth spur gear on the thresher which, in turn, drives an 8 tooth

spur gear. This final set of gear reduction drives a trio of 40

tooth gears acting as cutting wheels. Yellow bricks are inserted

into some of the stud holes in the gear to act as cutters.

The final gear reduction at the cutters is 9:1 with respect to the rear

wheels, so these turn very quickly when engaged (see animation).

They turn so quickly that this creates a lot of drag on the tire and

tends to make it slip.

|

Click for an animation of the thresher

in motion.

|

|

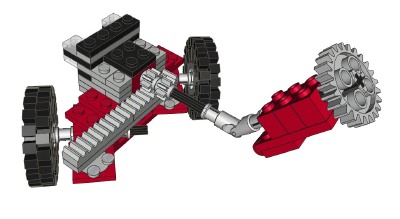

Lift

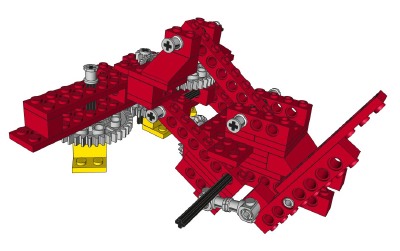

The thresher can be raised and lowered via a lever at the driver's

position on the right side. The lever pivots about the frame and

drives a push-pull link made from connectors. This link pushes a

four bar linkage which raises the implement, keeping it (almost)

parallel to the ground during motion. The reason it is not quite

parallel is that the vertical distance between the upper and lower

links is not equal at the front and the back, so the links are not

quite parallel.

As long as the model is right side up, the push-pull linkage is always

in compression so it tends to stay together. If the model is

inverted, this is in tension and can pop apart.

If the thresher is lowered too far, the 40 tooth gear will fall under

the PTO and jam. There are wheels on the thresher to make it

level and prevent this from happening.

The original mechanism (pictured) had a weak spot at the aft end of the

connector link. Only the friction on the studs kept this

together, so it tended to come apart often. In 1978, LEGO®

changed the design to have a vertical 1x4 beam at this location to hold

things together. This resulted in a slightly different parts list

and count for this set.

|

Click for an animation of the lift in

motion.

|

|

Wheels and Tires

This set uses two rubber 17x43 tires and standard old gray wheels on

the front. The rear uses a foam 24x43 tire and wheel, the biggest

foam tire that LEGO® made.

|

|