1st

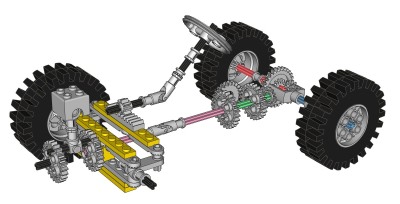

Model: Car

|

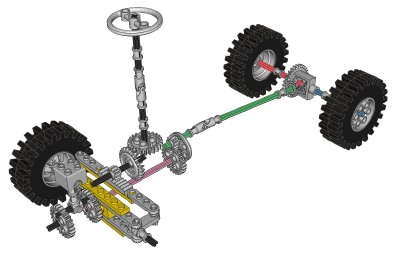

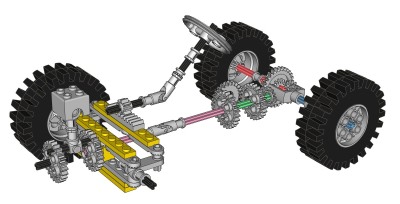

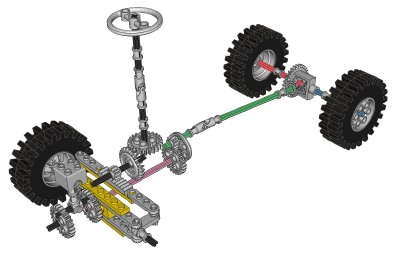

This

little

car has rack and pinion steering, a reciprocating one cylinder

engine, and a rear differential gear.

The front wheels can be steered using a wheel in the cabin. The

wheel drives an 8 tooth pinion gear through a

universal joint. The pinion drives the steering rack. The

steering mechanism itself uses

control arms and toothed links.

The engine uses the offset axle holes of the 24 tooth gears to make a

crankshaft. Connectors placed end to end and clocked 90 degrees

form rods which connect to a specialized 2x2 square piston. The

"cylinder" is actually square. The engine is driven from the rear

axles through a trio of 24 tooth gears (see color coded image).

The rear axle features a differential gear. It

incorporates a built in 28 tooth ring gear which can work either as a

bevel or a spur, similar to the 24 tooth crown gear. It is made

to house 3 14 tooth bevel gears. One is on each axle,

and one planet gear in the middle allows the axles to turn at different

rates. This addition results in very smooth turns for this model.

Oddly, this model does not make use of the shock absorbers which are

part of this set.

|

Click to download the LDraw

file of this model.

Model by Jerome Boulanger

Click for an animation of

the

steering in motion.

Click for an animation of

the engine in motion.

|

2nd

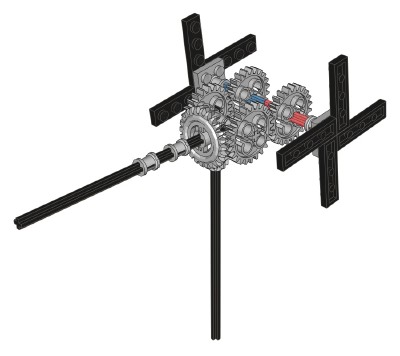

Model: Windmill

|

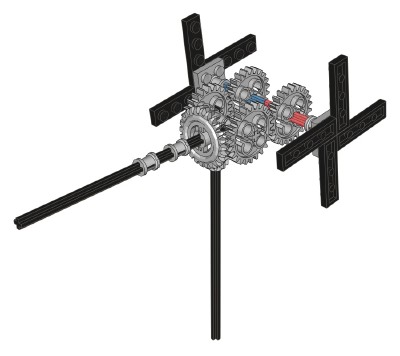

This

model

is a very nice looking, and very tall, windmill with rotating

primary and secondary vanes.

A crank (made of a 40 tooth gear) located in the back of the structure

near the bottom drives a vertical axle through a set of 14 tooth bevel

gears. This vertical axle drives a fairly complex gear box at the

head, shown in the computer image. The vertical 8 tooth pinion

drives a 24 tooth crown gear attached to the axle of the main

rotor. This same crown gear also drives a pair of 24 tooth spur

gears, one on each side, which rotate opposite directions. These,

in turn, drive a second set attached to the secondary rotors.

Because of the gearing, all the rotors turn at the same rate which is

1:3 with respect to the input crank.

|

Click to download the LDraw

file of this model.

Model by Jerome Boulanger

Click for an animation of

the windmill in motion.

|

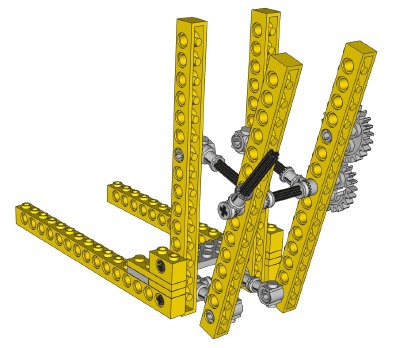

3rd

Model: Forklift

|

This

forklift

is a very nice, fairly complex model. It features

steering, lifting forks, and a kneeling front suspension.

The rear wheels can be steered using an overhead "hand of god"

wheel. The

wheel drives an 24 tooth crown gear through a

universal joint. The crown gear mates with a perpendicular 16

tooth spur gear attached to a pair of pinions. The pinions drive

the steering rack. The

steering mechanism itself uses

control arms and toothed links.

The forks are lifted via a 4 bar linkage. As can be seen in the

computer image, the lower links are shorter than the upper links.

The result of this is that the forks tips back as they are raised,

which can be seen in the animation. A lever attached to a toothed

connector is used to rotate the upper links and lift the forks.

This is a case where significant torque is carried across the teeth of

the bushing, but it performs admirably. A pair of 24 tooth spur

gears on the other side are used as a ratchet with a weighted

pawl. This keeps the forks raised.

The front axle features a differential gear. It

incorporates a built in 28 tooth ring gear which can work either as a

bevel or a spur, similar to the 24 tooth crown gear. It is made

to house 3 14 tooth bevel gears. One is on each axle,

and one planet gear in the middle allows the axles to turn at different

rates. In this model, the differential ring gear is not attached

to anything, so it really only follows along with the front axles.

A pair of springs on either side of the front axle swing arm allow the

entire model to "kneel". This allows the forks to slip under a

pallet before lifting.

|

|

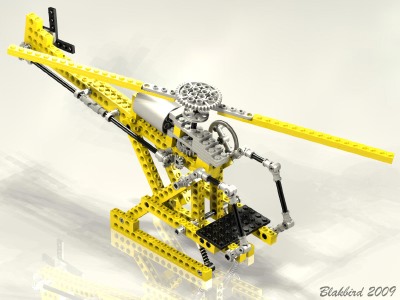

4th

Model: Helicopter

|

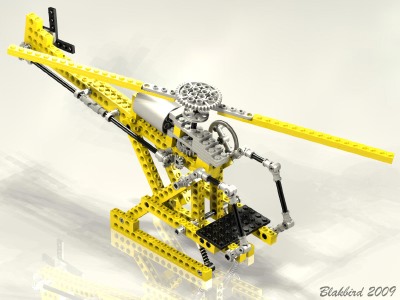

This

fairly

large helicopter features rotating main and tail rotors.

A crank on the port side drives both a 24 tooth crown gear and a 14

tooth bevel gear. The crown drives a 24 tooth spur gear on the

main rotor shaft. The bevel gear drives a perpendicular axle

which, through another set of bevels, drives the tail rotor.

Because of the gearing, both main and tail rotors are 1:1.

The model also uses shock absorbers on the front of the skids.

This is an odd feature which doesn't seem to mimic any part of a real

helicopter, but does provide some dampening on landing, I suppose.

|

Click to download the LDraw

file of this model.

Model by Jerome Boulanger

Click for an animation of

the rotors in motion.

|

5th

Model: Truck

|

This

large

truck has basically the same features as the car,

with the addition of peculiar rear suspension.

The front wheels can be steered using an overhead "hand of god"

wheel.

The

wheel drives an 24 tooth spur gear through a

universal joint. The spur gear mates with a perpendicular 24

tooth crown gear attached to a pinion. The pinion drives the

steering rack. The

steering mechanism itself uses

control arms and toothed links.

The engine uses the offset axle holes of the 24 tooth gears to make a

crankshaft. Connectors placed end to end and clocked 90 degrees

form rods which connect to a specialized 2x2 square piston. The

"cylinder" is actually square. The engine is driven from the rear

axles through a set of 8 and 24 tooth gears (see color coded image).

The rear axle features a differential gear. It

incorporates a built in 28 tooth ring gear which can work either as a

bevel or a spur, similar to the 24 tooth crown gear. It is made

to house 3 14 tooth bevel gears. One is on each axle,

and one planet gear in the middle allows the axles to turn at different

rates. This addition results in very smooth turns for this model.

The rear axle also features a swing arm suspension, but the motion is

forward-aft instead of left-right. The effect of this is that the

drive shaft pulls backward when the suspension travels, usually causing

the u-joint to separate.

The frame is very weak because it is only one beam deep, causing the

chassis to flex quite a bit under load. This is really the first

long truck model that LEGO® made, and this

problem would

be fixed with stiffer frames in later models.

|

Click to download the LDraw

file of this model.

Model by Jerome Boulanger

Click for an animation of

the steering in motion.

Click for an animation of

the suspension in motion.

Click for an animation of

the engine in motion.

|