1st

Model: Hockey Game

|

This

seems

to be a hockey player taking a slap shot at the goal. A

lever coming out of his backside rotates the whole upper body and

allows the stick to hit the puck, which is actually a 24 tooth crown

gear.

He's actually a pretty good shot!

|

Click

to download the LDraw

file of this model.

Model by Benjamin Wendl

Click for an animation of

the

slap shot.

|

2nd

Model: Handcar

|

Here

we

have a handcar such as you might see used by someone maintaining

railroad tracks. Movement of the front wheels turns a gear with

an offset axle which oscillates a vertical link. This link is

attached to the handle and causes it to pump up and down. Since

the "driver" is also attached to the handle and is hinged at the waist,

he follows along.

|

Click

to download the LDraw

file of this model.

Model by Benjamin Wendl

Click for an animation of

the handcar in motion.

|

3rd

Model: Rowboat

|

Now

here is something which never appeared in Technic before or since, a

rowboat! The motion of this oarsman is excellent.

The partially hidden rear wheels turn a gear with an offset steering

arm which oscillates a link. This link

is attached to the pelvis of the oarsman. His feet are pinned to

the boat, as are his hips. As the link oscillates, his body

position changes. The oars attached to his hands pass through oar

locks pinned to the boat. The animation shows all of this motion

very clearly.

|

Click

Click

to download the LDraw

file of this model.

Model by Benjamin Wendl

|

4th

Model: Motorcycle

|

This

little

motorcycle is clearly the weakest model of the set. It

doesn't really do anything other than turn the handlebars. No

animation necessary; use your imagination.

It could be argued that this is really a part of the next model since

it can be loaded in the back of the truck.

|

Click

to download the LDraw

file of this model.

Model by Benjamin Wendl

|

5th

Model: Flatbed Truck

|

This

truck

is quite sizable and full featured with steering, an adjustable

ramp, and a tilting cab. The flatbed in back fits the motorcycle

quite nicely.

|

Click

to download the LDraw

file of this model.

Model by Benjamin Wendl

|

|

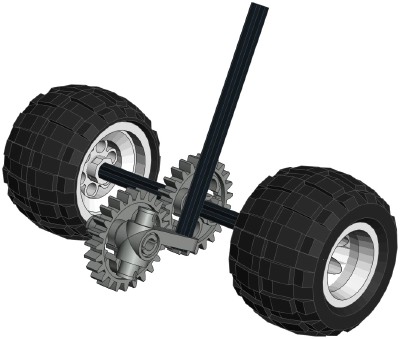

Steering

The front wheels can be steered using an overhead "hand of god"

wheel.

The

wheel drives set of 14 tooth bevel gears attached to a pinion.

The pinion drives the

steering rack. The

steering mechanism itself uses

control arms and toothed links.

The vertical axle actually disengages the bevel gears when the cab is

tilted forward.

It is unusual that this model has the steering arms facing forward

instead of backward like is usually seen.

|

Click for an animation of

the steering in motion.

|

|

Ramp

The ramp is driven by a crank on the left side. The crank turns a

worm gear which drives a 24 tooth crown. A universal joint moves the

axle up by one brick height, then a pair of bevel gears end the gear

train. The final axle uses a pair of pole reverser handles to

actually lift the ramp.

Because the mechanism uses a worm gear, it cannot be backdriven

(because the axial friction is higher than the backdriving torque due

to the screw pitch angle). This helps keep the ramp up when

in transit.

|

Click for an animation of

the ramp in motion.

|

|

Cab Tilt

The cab tilts forward via a crank on the right side. The crank

drives a pair of 14 tooth bevel gears which drive a worm. The

worm drives a 24 tooth spur gear attached to a pair of liftarms which

pivot the cab.

|

Click for an animation of

the cab tilting.

|

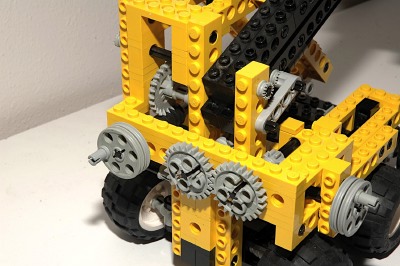

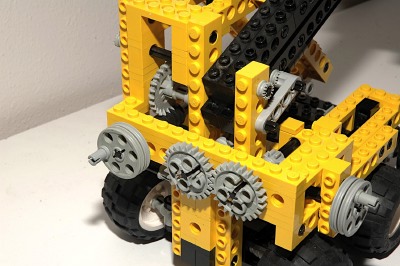

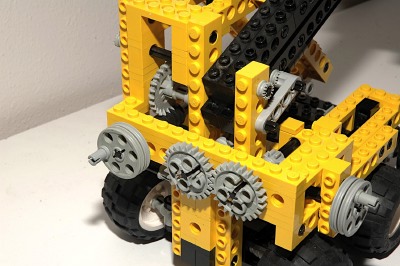

| 6th

Model: Loader |

This

interesting

model is something like a log loader, although the vertical

claw indicates something more like the machines which cut down

trees. In any case, it's pretty cool and has many features

including 4 wheel steering, a lifting boom, and a working claw.

|

Click

to download the LDraw

file of this model.

Model by Benjamin Wendl

|

|

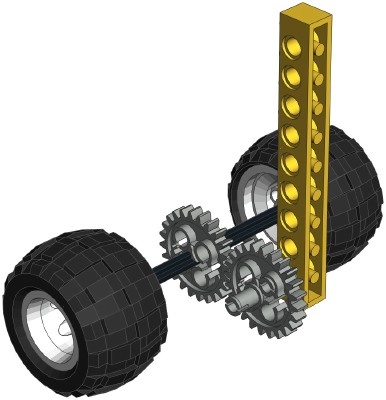

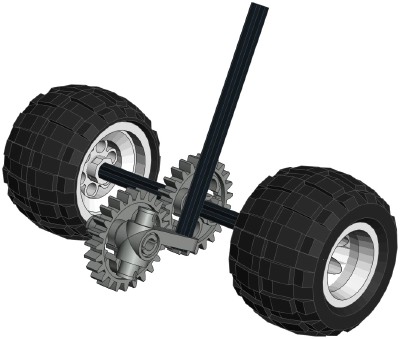

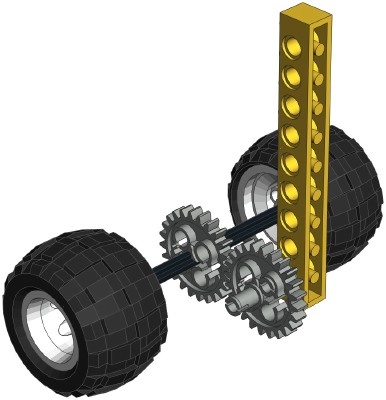

Steering

The front and rear wheels can be steered using an overhead "hand of

god" control which drives an axle connected to a pair of 14 tooth bevel

gears. Another set of bevel gears lead to a final axle which runs

to both the forward and rear gear racks which drives them in opposite

directions at the same ratio.

The steering mechanism itself uses the control arms and toothed links

as shown in the computer image.

|

Click for an animation of

the steering in motion.

|

|

Boom Lift

The boom luffs via a crank on the back. This crank turns a worm

gear which drives a 24 tooth crown. A pair of liftarms connect to

the boom.

Because the mechanism uses a worm gear, it cannot be backdriven

(because the axial friction is higher than the backdriving torque due

to the screw pitch angle). This helps keep the boom up so

it does not fall under its own weight.

The boom utilizes a 4 bar linkage to keep the end claw parallel to the

ground as the main boom angle changes.

|

Click for an animation of

the boom lifting.

|

|

Grasping Claw

The claw at the end of the boom opens and closes via a crank on the

right side. The crank turns a worm gear which drives an 8 tooth

pinion. Next come a pair of 24 tooth spurs. A pair of

u-joints allow the next axle to pass up the length of the boom and

still operate as the boom angle changes. At the end of the boom

are a set of 8 tooth pinions which feed a set of 14 tooth bevel

gears. Finally the two claws are linked together with a pair of

16 tooth spur gears which allows them to move in opposite directions.

Despite all the gears in this complex system, only one of them alters

the gear ratio and that is the worm set. Final ratio is therefore

8:1.

|

Click for an animation of

the claw in motion.

|

| 7th

Model: Helicopter |

This

tandem

rotor helicopter resembles a CH-47 Chinook. Though it is

mostly empty space, it is one of my favorite Technic helicopters as it

captures the look and feel very accurately.

|

Click

to download the LDraw

file of this model.

Model by Benjamin Wendl

|

|

Loading Ramp

The ramp is driven by a crank on the right side. The crank turns

a worm

gear which drives a 24 tooth crown. Next a pair of bevel gears end the

gear train.

The final axle uses a pair of pole reverser handles to actually lift

the ramp.

Because the mechanism uses a worm gear, it cannot be backdriven

(because the axial friction is higher than the backdriving torque due

to the screw pitch angle). This helps keep the ramp up when

in

transit. |

Click for an animation of

the ramp in motion.

|

|

Rotors

The tandem rotors are driven by a crank on the left side. This

crank drives a set of bevel gears. The first of these goes

directly up to the forward rotor. Another set of 14 tooth bevel

gears send the torque aft through yet a 3rd set and finally into the

aft rotor.

The rotors are counter rotating. Because they are geared

together, they can be clocked to not hit each other.

Additionally, the rotors are in different planes (aft is higher), so

they could not come into contact anyway.

|

Click for an animation of

the rotors in motion.

|