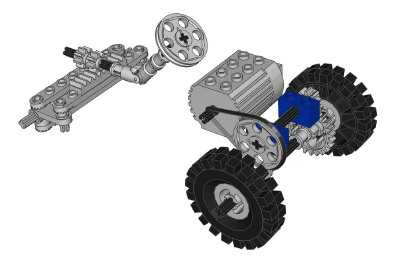

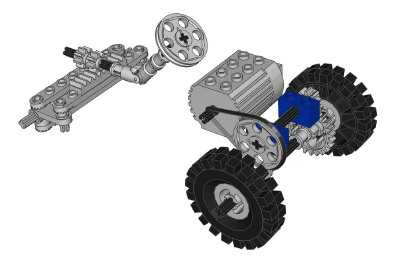

1st Model: Car

|

This

little car has manual steering and a motor driven rear axle.

The front wheels can be steered using a wheel in the cabin. The

wheel drives an 8 tooth pinion gear through a

universal joint. The pinion drives the steering rack. The

steering mechanism itself uses

control arms and toothed links.

The motor is mounted on the driver's seat and drives a pulley via a

belt which results in considerable gear reduction. The pulley

drives through a set of 8 and 24 tooth spur gears for yet another set

of

gear reduction. The 24 tooth gear is on the rear axle.

The rear axle helps hold the frame together and consequently carries a

bit of shear load which tends to make the axle bind.

|

Click for an animation of

the

steering in motion.

Click for an animation of

the car in motion.

|

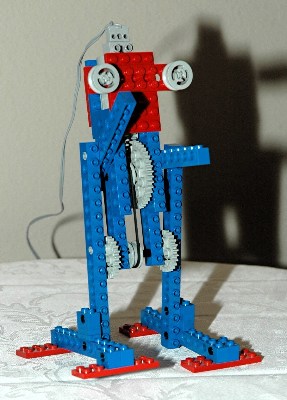

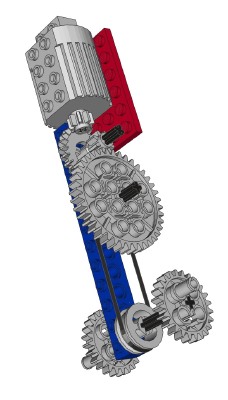

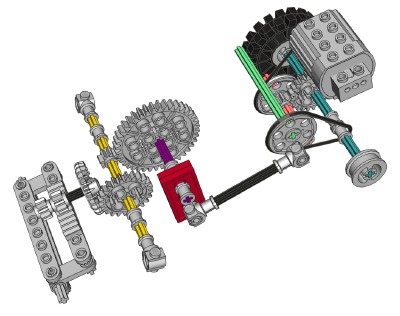

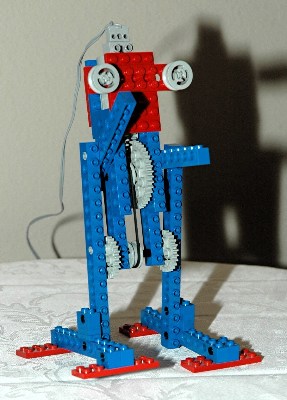

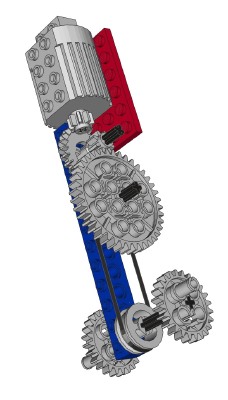

2nd

Model: Robot

|

LEGO®

gets big points from me for doing something other than a vehicle, but

this little robot isn't exactly Asimo. It "walks" in a manner of

speaking, but more realistically looks like it is having a seizure.

A motor mounted in the head of the robot has an 8 tooth pinion on the

output shaft which drives a 24 tooth crown gear. The next stage

is a set of 8 and 40 tooth spur gears which then drive a belt down to

the robot's "waist" where a pair of 24 tooth gears act as cranks using

the offset pin holes (see computer image). This final ratio of

15:1 sounds like a lot, but the legs still move way too fast to make

this guy stable. One of the Technic gear reduction boxes would do

wonders here, but would move the center of gravity even higher.

The top end of the "legs" attaches to the second hole of the "arms"

which makes them flail wildly while the robot attempts to "walk".

As you look at the animation, you can see that the motion is highly

nonlinear. First it moves very slowly, then it suddenly lurches

as the balance shifts to the next side.

|

Click for an animation of

the robot in motion.

|

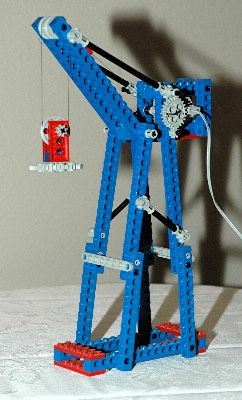

3rd

Model: Stationary Crane

|

This

free-standing stationary crane looks nice but doesn't do much.

A pair of trusses support a hoist system. The motor drives a

pulley via a belt, after which a set of 8 and 24 tooth gears turn a

cable drum. The cable then proceeds up the fixed boom and down to

a sheave. The sheave has its own pulley which further reduces the

motion 2:1 compared to the cable.

This system is hampered by the fact that the pulley axle (shown in red

in the computer image) also supports

the weight of the motor on the legs and therefore tends to bog down and

not turn

well.

|

|

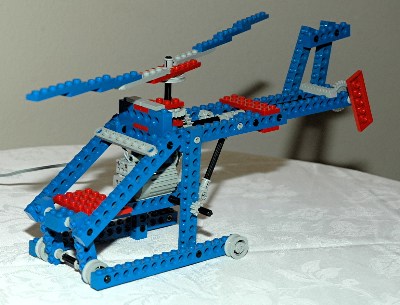

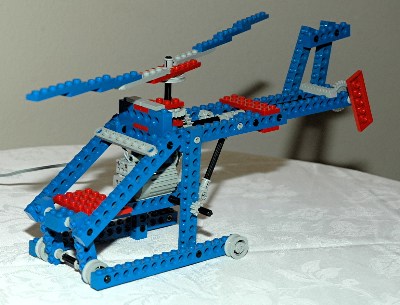

4th

Model: Helicopter

|

This

fairly large helicopter features rotating main and tail rotors.

The motor is mounted in the cockpit and drives a pulley via a

belt. Next, a set of 8 and 24 gears lead to an axle heading back

to the tail rotor. In parallel, a second 24 tooth spur gear is

actually used as a bevel gear. This is the only place I have seen

this done. Normally a crown gear would be used here, but the spur

gear was needed for other models in this set so it was all that was

available.

The rotors rotate well although the angular velocity of the main rotor

is far too fast with respect to the tail rotor (3:1). It should

be

the other way around.

|

Click for an animation of

the rotors in motion.

|

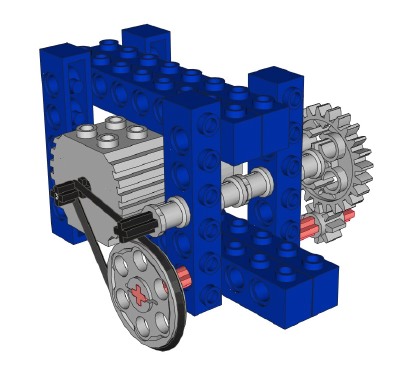

5th

Model: Buggy

|

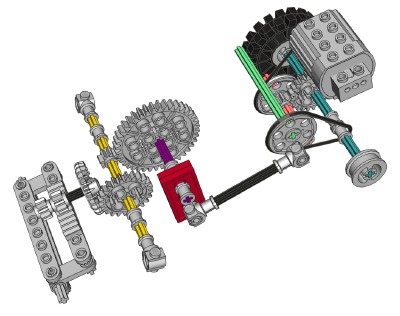

This

buggy has a unique mechanism which couples the motorized rotation of

the rear wheels to an oscillation of the front wheel steering.

As can be seen in the color coded computer image, the motor belt

drives a pulley

(red axle) which, through a set of 8 and 24 tooth spur gears, drives

the rear

axle (blue). The rear axle drives another pulley (green axle)

through a belt. This pulley acts as a crank and drives a

pushrod. This pushrod turns a crank in the middle of the vehicle

(purple axle) which controls the rack and pinion steering through a set

of 40

and 8 tooth gears, followed by a pair of 24 tooth gears (yellow

axle). The

steering mechanism itself uses

control arms and toothed links.

It is very important that the correct gear tooth be chosen when rigging

this system or it will tend to steer more in one direction that the

other.

Because the steering is belt driven, it tends to slip much of the

time. Even when working, the model doesn't turn very well because

of the solid rear axle. Still, this is a great model to

demonstrate how a variety of functions can work.

|

Click to download the LDraw

file of this model.

Model by Eric Albrecht

Click for an animation of

the mechanism in motion.

|